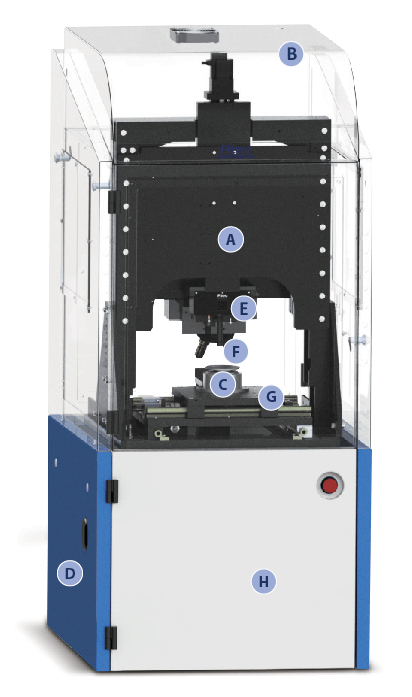

Tribometer MFT-5000 Overview

Main Features:

- Integrated 3D Profilometer

- Load Range Nano, Micro, Macro

- -120 °C to 1200 °C

- Modular with Interchangeable Modules

- Coatings, Lubricants, Materials Surface and Tribology Studies

Our Multi function tribometer is globally regarded as the most versatile and advanced. With patented force sensors, the MFT-5000 reaches super high speeds. As well as an extensive environmental control range, the MFT-5000 provides modularity. No other commercially existing tribometer performs our speeds and environments on one platform.

In addition, the tribometer contains a patented integrated 3D profilometer. This allows surface analysis of change vs. time. As a result, the MFT-5000 is perfect for comprehensive analysis of coefficient of friction, wear, hardness, adhesion, and more.

Need help or have a question?

A Tribometer Like No Other

Versatile and Customizable For Your Needs

Upper Z structure

High precision multiple Z stages to move load cell, and profiler in Z-axis

Open Platform

Open platform architecture allows easy access and use. In addition, large available space provides current or future application modules to mount on one platform.

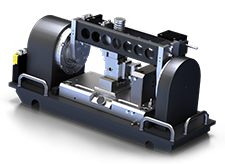

Lower Interchangeable Module

Interchangeable fast-exchange modules perform several tests on the same platform. These include rotary, block on ring, reciprocating, fretting, scratch, and more.

Environmental Control

Wide temperature (-120 to 1200°C), humidity (5 to 95% RH), pressure (up to 200 psi), vacuum (10-7 torr).

Force Sensors

Interchangeable load cells across a wide range—nN to 10,000 N. Capacitive, piezo, and strain gauge technology.

Patented In-line 3D Profilometer

In-line Lambda 3D optical profilometer. Inspect any sample with nm resolution. Four imaging modes on the same profilometer–confocal, interferometer, dark field, and bright field.

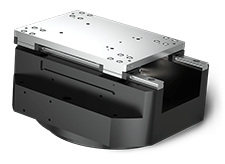

XY Stage

Long-stroke, high precision, close loop XY stage. The stage moves modules between test and image positions to create custom motions. Also, slow speed reciprocating, scratch, and combined X-Y motions.

Data Acquisition, Motion Controller

Advanced high speed, low noise, fast feedback. Multiple channels, and highest data acquisition rate (200 kHz) controllers.

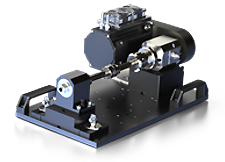

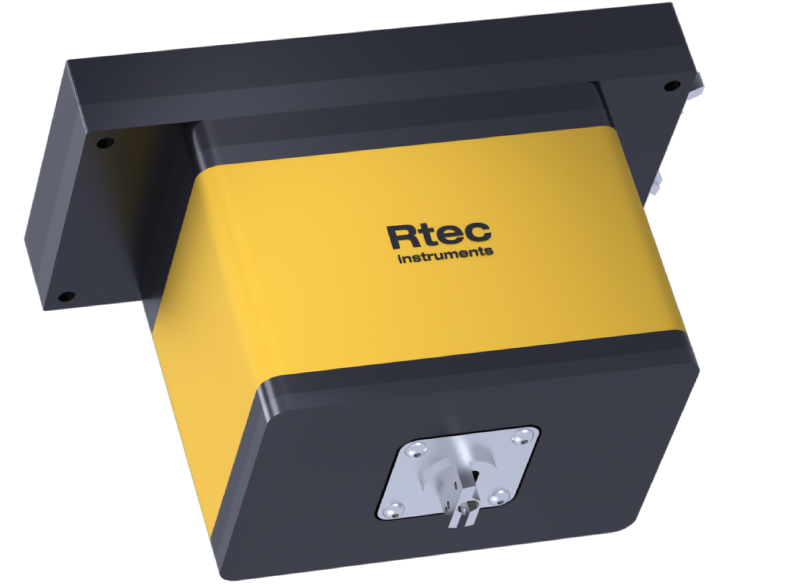

Interchangeable Drives

Our interchangeable modular drives boast versatile adaptability, seamlessly integrating electrified capabilities for precise control and enhanced functionality. These drives mount easily on the MFT-5000’s flexible platform, accommodating customizable tests tailored to diverse experimental requirements across a spectrum of research and developmental applications.

Rotary

0.001-10,000 RPM rotational speed

Upper Rotation

Twist compression up to 10,000 N loads

Linear Reciprocating

Wear, pin on plate up to 80 Hz

Block on Ring

Test bearings, shafts, lubricants, and grease

Mini Traction

Downforce 0 to 200N, speeds 6 to -6 m/s

Fretting Voice Coil

10 µm-2.8 mm stroke, up to 300 Hz frequency

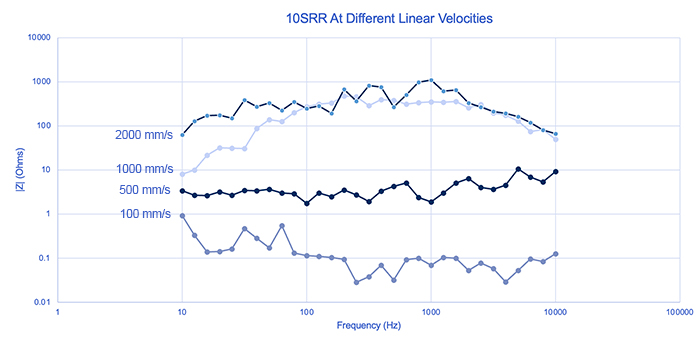

Measure Impedance vs. Changing Linear Velocities

Transition from Ohmic to Capacitive Behavior over lubrication regimes. By precisely measuring impedance against varying linear velocities, we provide valuable insights into the dynamic tribological behavior of materials under different speed conditions.

Patented Integrated In-line 3D Profilometer

The in-line integrated 3D profilometer provides 3D surface change plots with nm resolution. Thus, the profilometer easily correlates the tribology data with surface topography. This technology is specifically optimized for tribology-related tests.

Notably, the lambda head model combines four optical techniques on one head. These techniques include interferometer, confocal, dark field, and bright field imaging. Thus, it can measure any surface– transparent, rough, smooth, and steep slopes surface.

In addition, the XY stage on the tribometer allows for automatic stitching of volume wear and roughness calculations.

Two widely used optical head options are available for integration:

- Sigma head – White light interferometry

- Lambda Head – White light interferometry + Confocal microscopy + Dark Field + Bright Field Imaging

Unmatched Load Cell Technology

Capacitive, Piezo, And Stain Gauge

The universal mechanical tester has a wide range of patented load cells. This provides unparalleled stability and resolution. In fact, the wide load range extends from nN to 10,000 N with easily interchangeable load cells. In addition, the sensors come with various configurations: forces measured in 1, 2, or 6 axes.

Capacitive Load Cells

Highest resolution load cells with rigid design

Piezo Load Cells

Highest resolution load cells with high frequency response

Strain Gauge Load Cells

Sensors with widest load range

Dynamic Torque Sensors

Sensors for measuring in-line torque during rotating motions

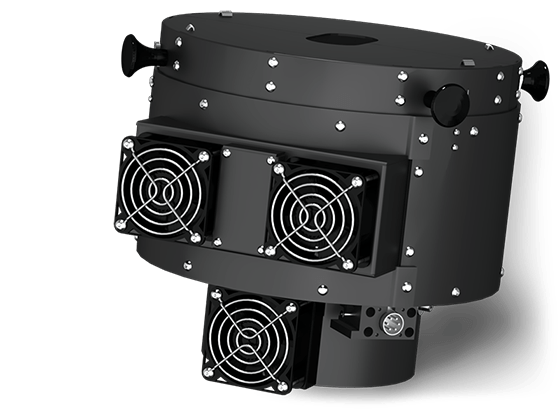

Environmental Chambers

Tribology testing highly depends on environmental conditions. Therefore, tests require conditions close to the real application. The MFT-5000 has a wide range of options. These include high temperature, corrosion, pressure, vacuum, cooling, inert gas on one tribometer.

Contact us for more application-specific information. Watch environmental control in action here.

High Heat and Cryogenic

Cryogenic to high temperature close loop chambers: -120 °C to 1200 °C.

Controlled Humidity

Control humidity from 5 to 95% RH to simulate real-life scenarios.

High Pressure and Vacuum

Solution from 10-7 Torr up to 200 PSI gas pressure with temperature control.

Environment

Salt Spray, tribocorrosion, inert gas chambers for various applications.

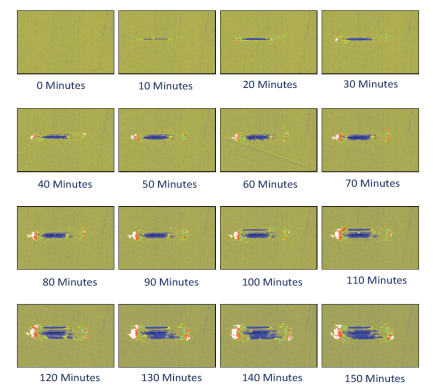

Automatic Sub nm Surface Change Image vs Time

The data shows 3D wear mark progression during a linear reciprocating test. Calculate and study:

- Volume wear progression

- Roughness change

- Crack initiation and propagation

- Debris creation

- Topography change

- Effect of textures for tribology testing

- Effect of surface roughness

Applications

Application-specific solutions

Rtec Instruments’ Universal Tribometer provides versatility and modularity. It supplies several tribological and mechanical testing solutions for various industries. Today, the MFT-5000 is widely used to measure the friction coefficient for lubricants and grease. Testing applications also include bio, automobile, semiconductor, aerospace, ceramics, space industries, and more.

It is essential to conduct experiments in conditions close to the real application. This is required for valuable tribological data. Meaningful data is now easy with the Universal Tribometer. This is because it provides custom motions and a wide load range, as well as customized holders and drives.

High Temperature (Up to 1200° C)

Mechanical

- Materials Summary

- Hot Hardness

- 3,4 Point Bending

Cryogenic

Corrosion Testing

- Tribocorrosion

- Salt Spray

Industrial

- Brake Materials Screening

- Lenses

- Cutting Tools

- Electric Vehicle Tribology

- Piston Ring Cylinder Liner

- High Pressure Chamber

- Space Tribology

- Textile

Solution To

Due to its multiple configurations, Multi Function Tribometer MFT-5000 tribometer is used extensively across a wide range of industries:

Aerospace

- Thermal Spray Coatings

- Wear Resistance

- Fretting

- Vacuum

- High Temperature

- Cryogenic

- Abrasion, Erosion Resistance

Automotive

- Brake Testing

- Marr Resistance, Scratch Adhesion

- Thermal Spray Coatings

- Oil, Lubricant, Additives Testing

- Fretting and Wear Resistance

- Engine Related Tests

- Tribology, Friction, and Wear

Bio-materials

- Coatings Adhesion

- Scratch Resistance

- Fretting and Wear Resistance

- Corrosion

Ceramics

- Scratch Resistance

- Tribology and Friction Testing

Hard Coating

- Indentation

- Scratch Resistance

- Fretting

- Turning and Tapping Torque

- High Temperature

Lubricants

- Block on Ring, Timken, OK, EP

- 4Ball Wear and EP

- Rotary pin, ball, ring on disk

- HFRR

- SRV

- Tapping Torque, TCT, Drilling

- Piston Ring Liner

- Thrust Washer

- Low Temperature Testing

- High Temperature Testing

- Linear Reciprocating

- Variable Rolling to Sliding

Metal

- Hot Hardness

- Scratch Hardness

- Tribology and Friction Testing

- High Temperature

Optics and Glasses

- Scratch Resistance

- Indentation

Pharmaceutical

- Tribology and Friction

Polymer

- Scratch Resistance

- Indentation

- High Temperature

- Turning and Tapping Torque

Semicon

- Indentation

- Scratch Resistance

- Tribology and Friction Testing

Need Compact Tribology?

Check out the benchtop Multi Function Tribometer, the MFT-2000 Series.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved