Multi Function Tribometers

The versatile MFT series tribometers offer multiple precise and comprehensive tribology tests across various applications. Whether examining friction, wear, or material properties, the MFT tribometers deliver accurate and reliable results, making them indispensable tools for researchers and engineers in various industries.

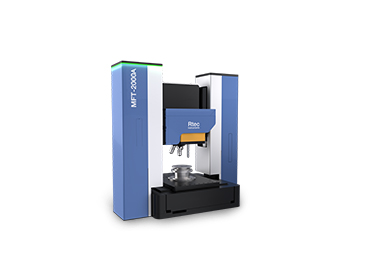

Single Function Tribometers

These tribometers are optimized to provide specialized testing solutions, offering focused and reliable assessments for specific tribological parameters. Designed with precision and expertise, these instruments cater to the distinct needs of industries, delivering targeted insights into friction, wear, and material properties.

Reasons For Choosing Rtec Tribometers

Rtec-Instruments integrates cutting-edge tribology testing technology into their tribometers, enlisting the latest innovative features that often address emerging industry needs, ensuring that users stay at the forefront of tribological testing technology.

Technology

The only global tribometer manufacturer that possesses wide technology experience: from force sensors (capacitive, strain gauge and piezo load cells) to optical profilometry (Nipkow disk confocal microscope and white light interferometer) through voice coil and servo motors. With this in-house expertise, we provide world-class tribology solutions.

Future

Rtec Instruments is an application-driven company. We work closely with our international industrial and university partners to develop new functionalities in mechanical surface testing and optical profilometry, resulting in numerous patents. With constant innovation, we are today’s de facto standard for future needs.

Diverse Application Usage

Today several Fortune 500 companies and top global universities use Rtec Instruments products. With an ever-growing number of users, our tribometers have become the tribology testing equipment standard across a wide range of applications.

Application Support

Our team has 20 years of experience manufacturing tribology testing equipment for the most advanced applications. Additionally, our US, Europe, and Asia tribology experts are ready to provide outstanding application and local support, from understanding tribology data to full application development.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved