Semiconductor

With a large range of analytical systems, Rtec Instruments provides several semicon solutions to evaluate touch screens, devices, organic layers, coatings, PCB, consumer goods, and more. Whether it’s research or development, our versatile instruments supply the semiconductor industry with the knowledge to produce quality products.

Semiconductor Testing Solutions We Offer

So many choices. So much data. Our instruments investigate and yield comprehensive analysis for every stage of semiconductor production and quality control.

Scratch Adhesion, Hardness

Friction, Durability, Wear Resistance, Perception, Touch

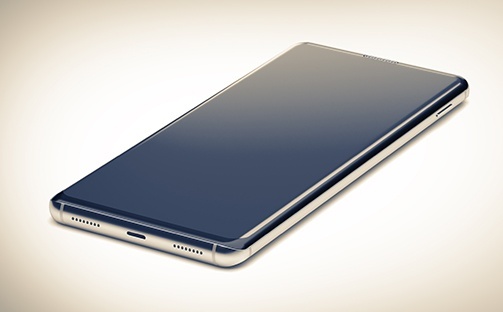

Characterize friction, durability, and wear of coatings, touch screens, optical surfaces, consumer goods, and lenses with various multi level coatings. Quantify perception, touch, static, and dynamic coefficient of friction under wide testing parameters, motion, and controlled environmental conditions.

Curved and Flat Screen Surfaces

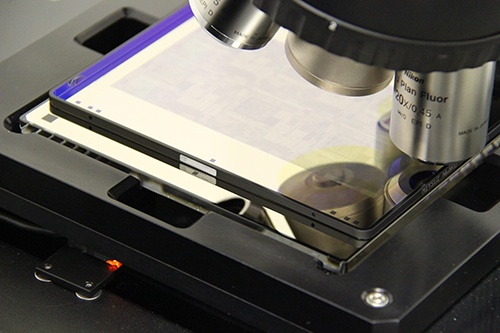

Characterize the roughness, defects, scratches, and features using our unique optics technology. Study transparent, curved, or flat screens and glass surfaces with ease. In addition, study coating adhesion on surfaces or devices with our scratch tester.

Pellicles

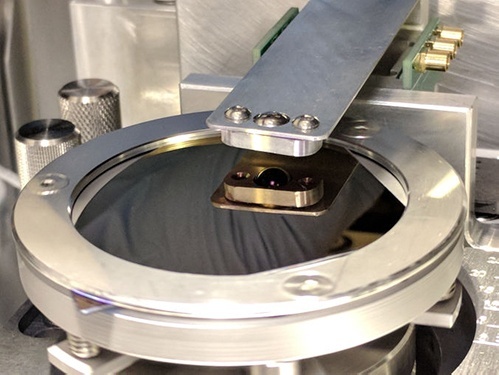

Increase the yield and process efficiency by avoiding stripping and remounting pellicles. Test the position of the particles on pellicle. The unique technology allows quantification and finds if particles are below or above pellicle surface.

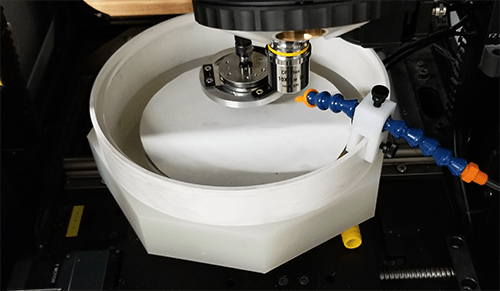

Chemical Polishing

Study and characterize the CMP process like never before. In addition to polishing wafers & substrates, the tester comes with in-line surface profilometer.

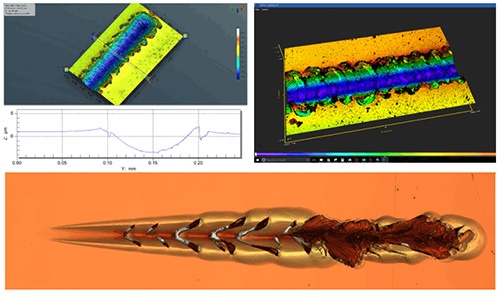

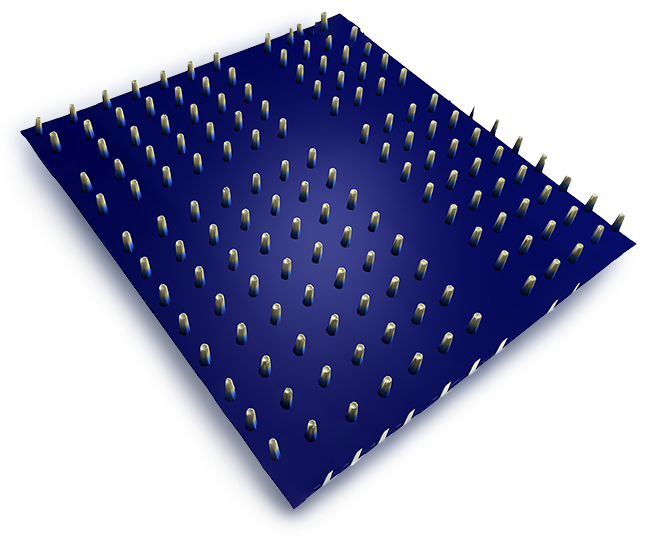

Semicon 3D Imaging

The unique all-in-one universal profiler combines 4 imaging modes (confocal, interferometer, dark field and bright field) on one head. This is very beneficial for semicon industry as advantages from all techniques are available to use together seamlessly. Few industry standard applications include particle on pellicle, highest XY dimension resolution on devices, and imaging transparent screen surfaces in one instrument.

Semiconductor Testing In Action

Watch as we demonstrate how our instruments provide semiconductor testing solutions.

Need Versatility?

Need Fretting?

Need Indentation and Scratch Testing?

Need 3D Microscopy?

Check out our 3D Optical Profilometers, the UP Series

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved