Automotive

Rtec Instruments provides automotive industry solutions for evaluating friction, wear, adhesion, hardness, roughness, and mar resistance on coatings, materials, and components.

Automotive Solutions We Offer

We deliver mechanical and surface testing automotive industry solutions for all quality control and and research applications

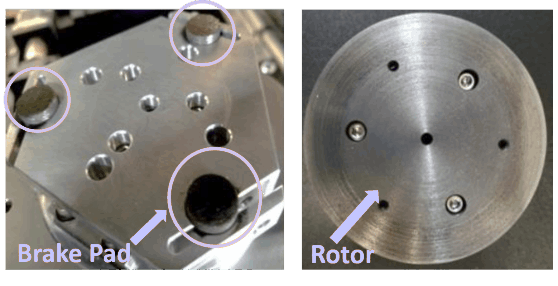

Brake Testing

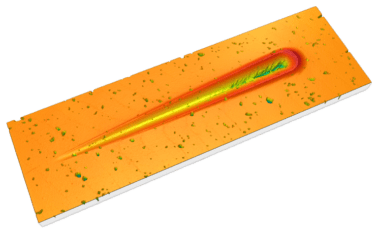

Marr Resistance, Scratch Adhesion of Paint, Coatings

The automotive industry has extensively used composite coatings for automotive body panels. Faced with environmental challenges, top level coatings require high clarity and gloss to achieve the desired visual effect over long periods of time. Study marr resistance, scratch adhesion, scratch hardness, durability, wear resistance at nano, micro, and macro scale.

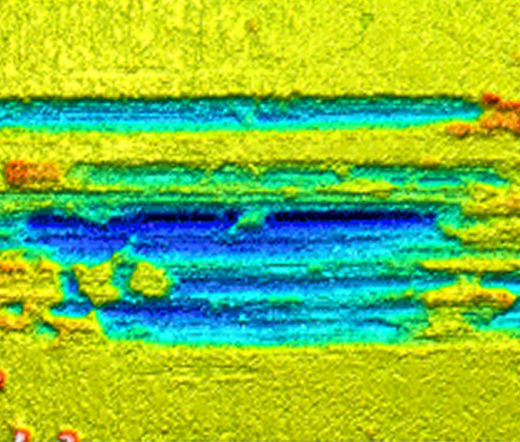

Thermal Spray Coatings

Various thermal spray coatings for a wide range of engine transmission, steering, suspension, and several other components on automobile parts are used to reduce wear and corrosion. Rtec Instruments offers solutions to measure thermal spray coating adhesion, friction, hardness, wear, durability, roughness, corrosion resistance, abrasion resistance, surface roughness and many more across a wide range of test conditions.

Oil, Lubricant, Additives Testing

Test oil, lubricants, additives, grease, and more using several ASTM, DIN, ISO standards. Test several standard and customized tests across a wide range of load, speeds, test temperatures. These can be rotary, block on ring, 4 ball, SRV, HFRR, linear reciprocating, EP wear modes, and more.

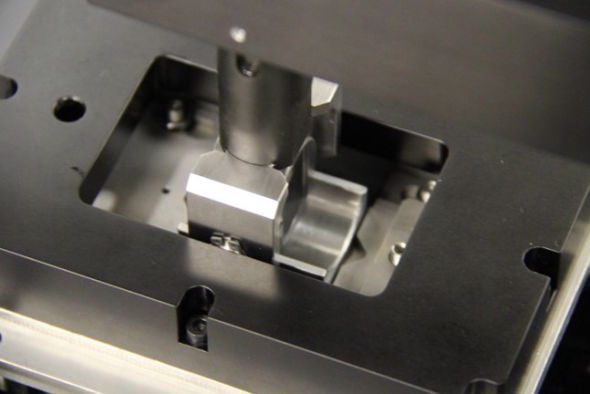

Fretting and Wear Resistance

Our tribometers and fretting testers provide unequaled specifications for stroke and frequency in the industry. Controlled stroke from 5 microns at 500 Hz frequency across a wide temperature range makes it an ideal fretting wear tester for both automotive industrial quality control and university research.

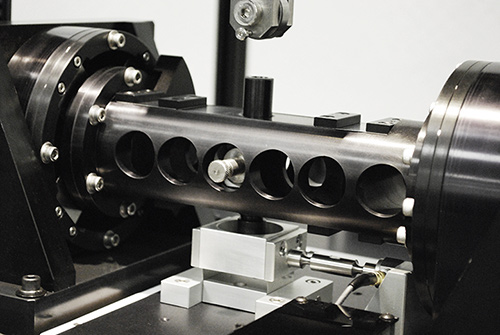

Engine Related Tests

Rtec Instrument offers several solutions for engine related tests to measure friction, wear, adhesion, roughness, fretting and more. Study piston ring liner friction and wear at engine speed on a lab scale. Test engine additives using our HFRR and SRV test setup. Study DLC and other coating adhesion using our scratch test setup. Study fretting failures on engine component due to constant vibrations.

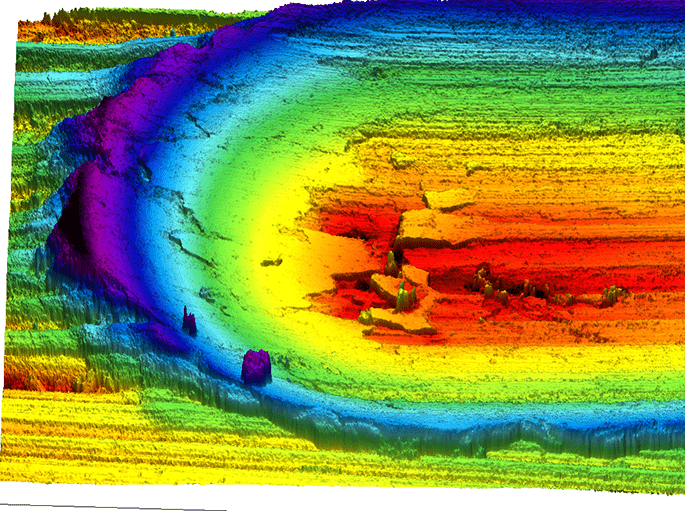

Automotive 3D Imaging

Combine 4 imaging modes in one head. It requires only one mouse click to alternate between the different imaging modes. Image any surface with ease – transparent, flat, dark, flat, curved, and more.

Tribology, Friction and Wear

Perform tribology, friction, wear, fretting, and much more under a wide testing load range from mN to 12,000N. Tribology tests available during a variety of controlled environmental conditions. Test automotive coatings, materials, components, bearings, wipers, wheels, brake, engine coatings, and self-healing coatings with ease.

See It In Action

Watch as we demonstrate how our instruments can fulfill all of your automotive industry applications.

Need Versatility?

Take a closer look at the Multi Function Tribometer.

Need Fretting?

Check out our FFT Fretting Testers Series

Need Indentation and Scratch Testing?

Learn more about our Indentation and Scratch Tester, the SMT-5000.

Need HFRR Testing?

Check out our Benchtop HFRR Tester, the FFT-M

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved