CP-5000 Chemical Mechanical Polisher Overview

Main Features:

- Real-Time Coefficient of Friction

- Controlled Down Force and Speed

- Integrated 3D profilometer

- Several wafer sizes can be mounted

- In-line Temperature and Acoustic Emission to study process

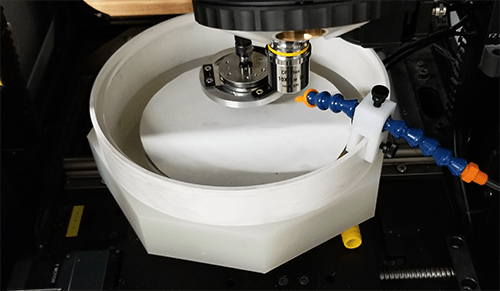

Advance your process and product development with our CMP R&D polisher. We optimized product development by providing several polishing processes on one platform. These processes include a wide speed range, closed-loop downforce control, versatile wafer holders, and an automatic slurry delivery system. Additionally, the CMP tester monitors several in-line signals during the polishing process.

Besides polishing wafers & substrates, the tester comes with an in-line surface profilometer. This combination explains how the surface, friction, and surface wear changed and why imperfections occur.

Need help or have a question?

CMP Tester Features

Unmatched Load Cell Technology and Speed

During the polishing process, high resolution in-line force measurements quantify interfacial interactions. To optimize the process, the CP-5000 provides full control of down force. This includes speed and flow rates based on customized test protocols.

Pad Conditioner

Self-leveling upper pad conditioner holder with both active rotation and horizontal oscillations.

Accommodates conditioner from 0.5 “to 4.25”

Reliable and Accurate

Each CMP Tester is versatile with many sensors and temperature options. The motorized XY stage comes with fast exchange, providing meaningful data with ease.

Ease Of Use

The CP-5000 comes with Fast Exchange carriers. As a result, quick and easy mounting of wafer and pads is achieved. The software comes with predefined standard test recipes. The user keeps the ability to easily create new custom recipes.

In-line Sensors

Acoustic – Acoustic signal that allows qualitative end point. As well as, aids in debris and defects detection during the polishing process.

Temperature – In-line temperature monitoring of pad and area close to wafer polishing surface. This aids in the study of the removal mechanisms.

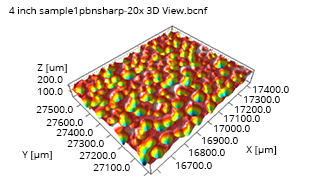

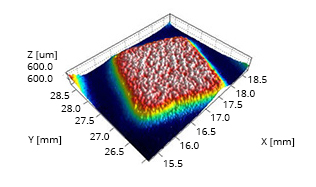

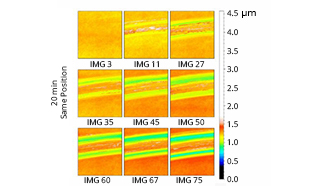

Patented Integrated In-line 3D Profilometer

Characterize pad surface with nm resolution. The profiler comes with confocal, interferometer, dark field, and bright field modes. The chemical mechanical polisher provides automatic stitching across large surface areas. Essential for volume wear and roughness calculations.

Pad 1 Surface

Pad 2 Complete Bump Feature

3D Surface Change vs Test Runs

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved