Metal

Rtec Instruments provides several ASTM, DIN, ISO standard and customized metal testing to evaluate wear resistance, friction, steel, aluminum, inconel, and much more. Our variety of analytical systems supply the metal industry with the tools necessary to evaluate metal quality control and quality assurance in every stage of development.

Metal Industry Solutions We Offer

With our modular platforms, there are so many choices and options available to assess metal performance in all types of environments.

High Temperature

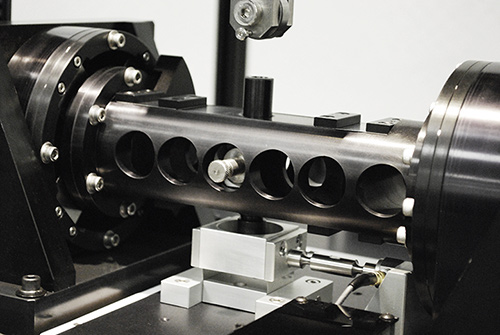

Fretting

Fretting studies in the metal industry are of critical importance. Rtec Instruments provides unequaled fretting evaluation thanks to our stroke and frequency control. Controlled stroke from 5 microns, frequency up to 500 Hz frequency, and a wide temperature range. Rtec Instruments’ fretting wear tester are pertinent in aerospace, automotive, power plant, and turbine applications.

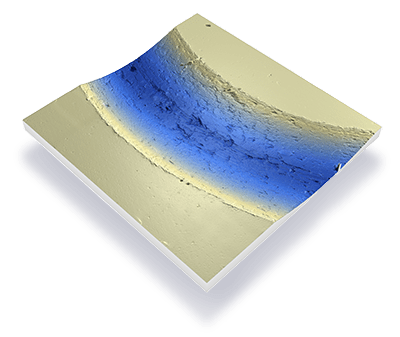

Coatings

Several applications require coated metal surfaces. Based on the coating process or the metal surface, the end results can be very different. Rtec Instrument provides solutions to characterize coating adhesion, scratch hardness, scratch resistance, wear, durability, fretting, roughness, corrosion resistance, and abrasion resistance. We provide tests at nano, micro and macro scales across a variety of temperatures and conditions.

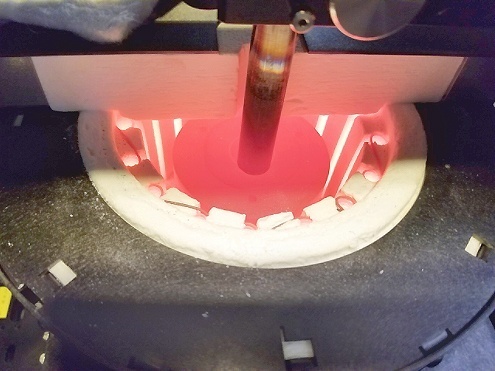

Friction, Wear Studies

Perform tribology, friction, and wear tests under load ranges from mN to 12,000 N. Controlled environmental condition from -120°C to 1200°C, vacuum, and high pressure are also available. Rotary, linear reciprocating, fretting, and block on ring modes of choice depend on the application.

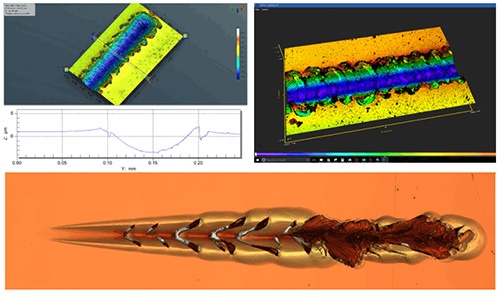

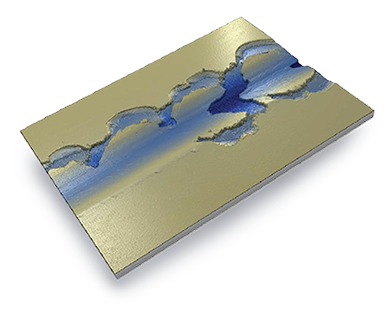

3D Imaging

Combine 4 imaging modes in one head. It requires only one mouse click to alternate between the different imaging modes. Image any surface with ease – transparent, flat, dark, flat, curved, and more.

See It In Action

Watch as we demonstrate how our instruments can fulfill all of your applications.

Need Versatility?

Need Fretting?

Need Indentation and Scratch Testing?

Need 3D Microscopy?

Check out the our 3D Optical Profilometers, the UP Series.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved