Quality Control of Hard Coatings Introduction

The ceramics coatings deposited by PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) techniques, designated here as “hard coatings”, are used in general for their wear and corrosion resistant properties and/or low friction properties. Different parameters (composition, microstructure, thickness, internal stresses, adhesion strength, hardness, ductility, toughness, thermal stability) would influence their wear and friction properties as well as their chemical resistances.

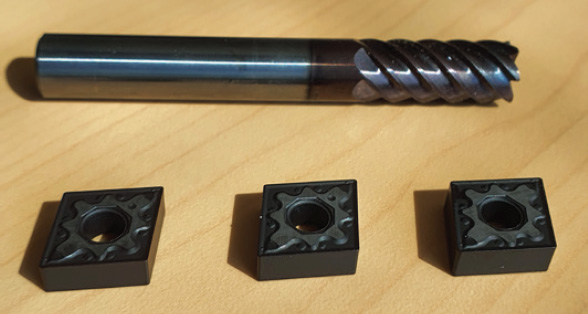

Figure 1: Typical applications of PVD coatings: inserts and cutting tools

Different methods of testing have been used for the characterization of the mechanical properties of hard coatings. Tribological measurements provide useful information on the essential properties related to their final use in real applications, i.e coefficient of friction and wear. Instrumented indentation testing provides information on hardness and elastic modulus of the coatings. But none of these methods would give meaningful information on the control quality of the deposition process. Scratch testing is measuring the adhesion and scratch resistance of coatings and providing unmatched information on the mechanical integrity of the coating-substrate system. Different aspects for the scratch test method for quality control are detailed in this Application Note.

Need help or have a question?

Principles of Testing

For manufacturing parts, it is of the highest importance to be able to quantify that the same identical parts are produced each time. The scratch testing method allows to quantify precisely and ensure the correct performances of the hard coatings, i.e adhesion, consistency of coating internal stresses, and deposition process (cleaning of substrate, quality of surface substrate, quality of deposition process, deposition equipment in good working function). For quality control of hard coatings, we refer mostly to the norm ISO 20502 (and also to ASTM C1624-05) which explains the testing method:

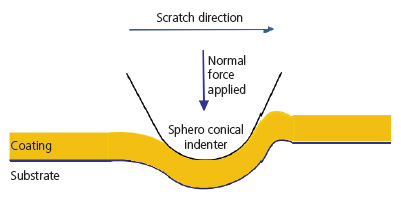

“The scratch test is designed for the assessment of the mechanical integrity of coated surfaces. The test method consists of generating scratches with a stylus of defined shape (usually a diamond with a Rockwell C geometry) by drawing it across the surface of the coating-substrate system to be tested, either under a constant or progressive normal force (Fig.2). Failure events are detected by direct microscopic observation of the scratch and sometimes by using acoustic emission and/or friction force measurement.”

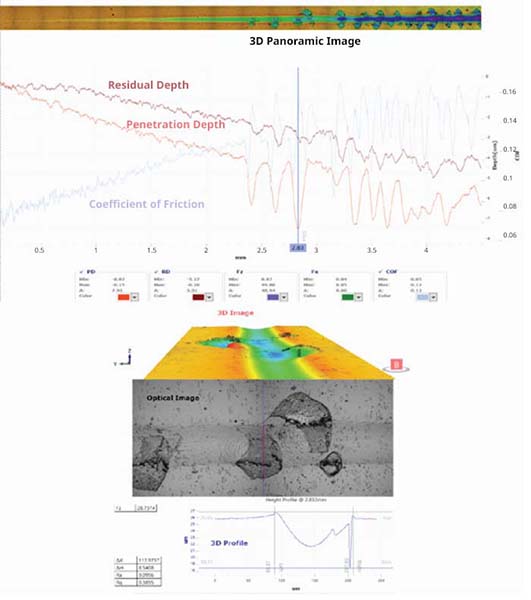

A test with constant or increasing forces can be considered. The interest of the increasing force is to determine in a single test the critical loads, and therefore the critical stresses, at which the cohesive and/or adhesive failures are observed. By a relatively quick test, the critical load for which the coating adhesion is failing can be measured, as shown on Fig. 3.

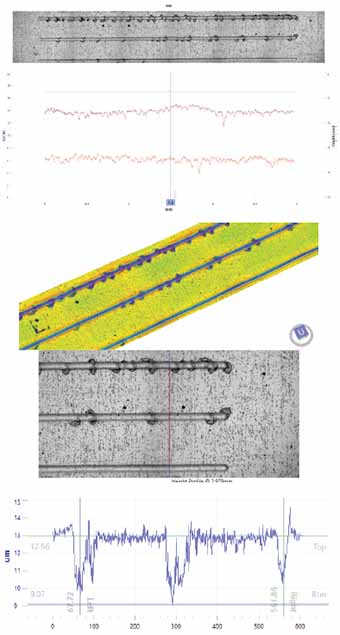

Figure 3. Principles of the data analysis of the scratch results with in-line 3D imaging on a TiN coating

Characterization Method

“The force is applied to the stylus so as to promote adhesive and/or cohesive failure of the coating substrate system.“

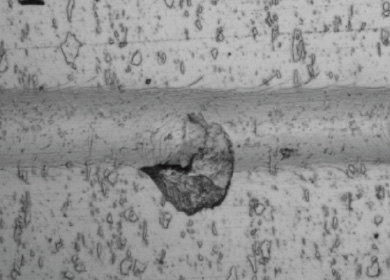

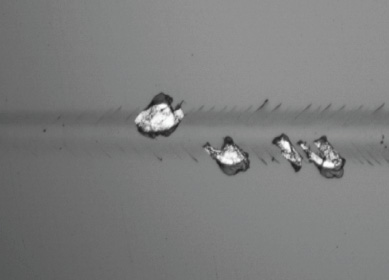

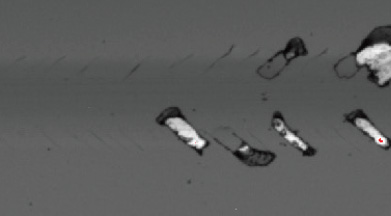

Differences between failure modes are interesting to observe: adhesive failure (delamination at the interface coating-substrate, typically observed on DLC coatings) or cohesive failure (spallation inside the coating, typically observed on TiN coatings) provide an interesting view on the mechanical strength of the sample (see Fig. 4).

Figure 4a: Cohesive Spallation

Figure 4b: Adhesive Delamination

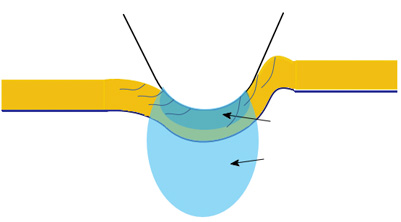

“The driving forces for the failure of the coating substrate system in the scratch test are a combination of elastic-plastic indentation stresses, frictional stresses and the residual internal stress present in the coating. The normal force at which failure occurs is called the critical normal force Lc.”

The critical normal force, Lc, is linked therefore to the mechanical integrity of a coating-substrate system (or multilayer coating-substrate). The mechanical stresses in the system can be schematically represented as on Fig. 5.

“It is quite common to characterize the onset of cracking by the critical normal force Lc1, while the onset of coating detachment defines the critical normal force Lc2. In general, a series of failure modes are observed and used to study the mechanical behavior of the coated surface, where the onset of the nth failure mode defines the critical normal force, Lcn.”

The Lc1 is generally considered as the appearance of the first cracks, the Lc2 as the first delamination or spallation, and the Lc3 as the full delamination. Examples of Lc1, Lc2 and Lc3 are illustrated on Figure 6a-c.

Figure 6a Lc1: First Cracks

Figure 6b Lc2: First Delamination

Figure 6c Lc3: Full Delamination

It is possible that one of the 3 main critical normal forces, Lc(n), may not be clearly visible by optical observation or detected easily by one of the optional sensors (AE or friction force). A short study would allow to evaluate quickly the most adapted parameters for an easy detection in Quality Control (visual, AE, friction and/or depth).

The determination of the critical normal force, Lc(n), also commonly accepted name of critical loads, Lc(n), could represent the aspect of testing which is the most subject to interpretation. The challenge may lie on two aspects:

- Difficulty of detection: typical cracks in hard coatings can be detected with the Acoustic Emission (AE) sensor but can be difficult to observe optically. It is therefore worthwhile to investigate which detection method (microscopy,

penetration depth, AE or friction) is the more valuable for this detection; - Misinterpretation: some failure modes can be interpreted differently by various users.

But in Quality Control, these errors can be easily eliminated from the beginning on the first study. The modes of failures on a specified coating-substrate system are highly reproducible (i.e TiN coatings show typical cohesive failures while DLC coatings tend to display adhesive failures). It is also easier to decide which Lc(n) are the most meaningful without possible misinterpretation.

Specific Aspects for Scratch Testing in Quality Control of Hard Coatings

Indenter Tip Characterization

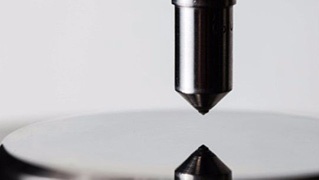

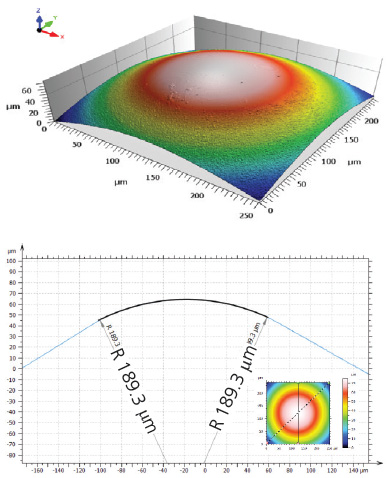

One of the essential experimental parameter of influence of the scratch testing method, which can be overlooked, is the exact geometry of the spherical indenter tip and its regular control.

The test by itself corresponds to a strong mechanical interaction between a sphero-conical indenter and a coating surface, for which the results is highly dependent on small variations of the local contact area. Therefore, it is extremely important to regularly check the quality of the tip.

Rtec-Instruments is proposing an integrated confocal microscope to the scratch tester, which allows a fast indenter tip control with a high resolution 3D image. Tip damages or contaminations can be observed easily. A regular cleaning of the tip by ultrasonic bath and/or mechanical polishing is helping to ensure an effective consistent contact area for scratch tests. This process

can be implemented in the control procedure of the scratch testing method.

Figure 7: Determination of tip radius with integrated confocal microscope for 3D imaging

Figure 8. DLC coating used as a certified reference sample

Instrument Verification and Recalibration

An appropriate recalibration of the instrument, especially for the normal force, is useful for full certification. But for an easy and regular verification of the instrument (on a weekly basis or after a series of tests), a reference sample with certified values of Lc(n) exists and can be used.

The certified reference sample has the significant advantage to provide both at the same time a verification of the instrument and of the scratch indenter tip, the indenter tip being one of the other important parameters to be verified as well.

Geometry and Surface Roughness

Thanks to the advanced force feedback loop control of the measuring heads, the force applied is continuously monitored and the position of the head adapted to the sample geometry. Testing on cylinders and spheres can be performed, the main physical limits being the indenter tip size and geometry in contact with the sample surface. Adaptation of tips can be designed easily for special geometries.

It is recommended to have a uniform statistical roughness, and in the best conditions, the surface roughness Ra, would not exceed 0.5 μm. In real manufactured parts, this ideal value may not be reached but it does not impede to perform scratch tests on very rough surfaces and conduct analysis of results. The only drawback is the higher dispersion of data to be considered. Rtec-Instruments is offering an integrated dual white light interferometer (WLI) and confocal microscope for a full view of mechanical and surface characteristics of hard coatings.

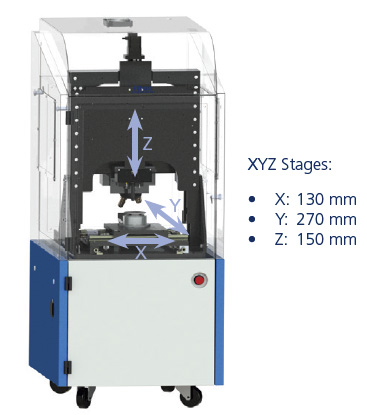

Figure 9. Large automated and motorized platform for programmable scratch tests and 3D images (WLI and confocal)

Automation for Quality Control of Hard Coatings and Multiple Sample Programming

The large computer controlled motorized stage (X,Y,Z: up to max 130 mm x 270 mm x 150 mm) with programmable optical and 3D imaging capabilities allows offering an advanced automation system for quality-control of hard coatings. It is possible to include a multi-sample holder for complete acquisition of scratch test results: all sensors with optical or 3D images. By saving operator time, the return on investment is significantly increased.

Modes of Scratch Testing For Quality Control

Progressive-Force Scratch Test

The normal force applied by the indenter increases linearly as the indenter moves across the test surface at constant speed. As the force increases, the indenter gradually penetrates into the layers. As the penetration depth increases, the stresses induced by the diamond increases as well. For hard coatings (2 – 6 mm), with a Rockwell 200 mm radius and following the international standards, we suggest parameter values of 100 N/min and 10 mm/min. If the critical load used for failure is lower than 10 N, a lower loading rate is recommended. During the Scratch, at certain force– the critical loads (Lc) like cracking, spallation, full delamination… are reached, this is the force value (pressure) that causes material the failure.

Constant-Force Scratch Test

The normal force is increased step by step between successive scratches carried out under constant normal force, at different locations on the specimen surface until failure occurs. Using one-fifth of the critical normal force determined by the progressive-force scratch test, a series of scratches are produced at increasing normal force using an indenter traverse speed of 10 mm/min. A new series of scratches using lower normal-force increments can be used to investigate any regions of interest more closely.

The interest of the constant force is to determine either the critical loads of failures with the utmost precision or the uniformity of the sample by scanning large areas of the surface. The constant force can be run in automated multiple tests (with a constant force increased at each test series) in order to obtain statistically and with the highest precision the critical loads of first cracks, first delamination and full delamination.

It happens that for the practical reason of time limitation, the constant-force scratch test has been less used in industrial applications than the progressive-force scratch, because the latter one is much faster while providing reliable enough data.

Figure 10. Constant force measurement with integrated 3D imaging

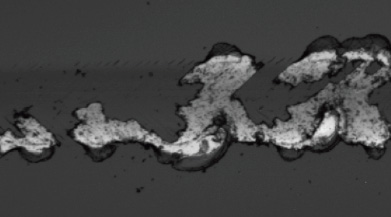

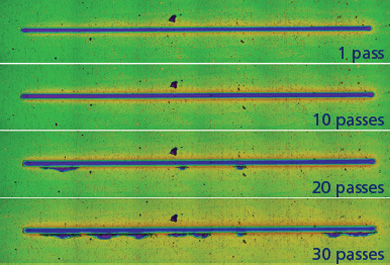

Multi-Pass Scratch Test or Tribological Test

The specimen is subjected to repeated scratching, within the same scratch track, under a constant subcritical normal force. Using a normal force of 50 % of that determined under the progressive-force scratch mode, an indenter traverse speed of 10 mm/min and a scratch length of at least 3 mm, the sample is tested until failure occurs. This mode represents a low-cycle fatigue-type contact, which is closer to the real working conditions, but also more equivalent to a tribological test. The scratch tester can then be used like a tribometer in a linear reciprocating oscillating mode.

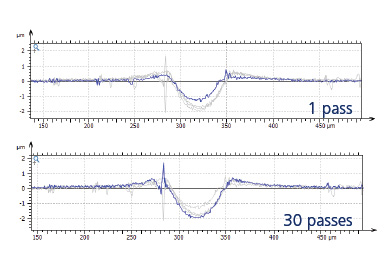

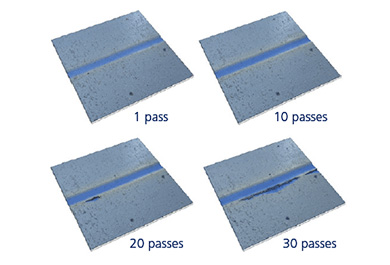

Figure 11a. Evolution of a mutlipass constant scratch at 15 N on TiN

Figure 11b. Superposition of the profile during multipass constant scratch test at 15 N on TiN coating

Figure 11c. 3D image of the multiscan at 15 N

Interest of Quality Control with the Scratch Test Method and Conclusions

Coating-substrate parameters relevant to the scratch test, and then to the final use of the manufactured coated parts, are the mechanical properties of substrate and coating, coating thickness, internal stresses in the coating, and friction coefficient between coating

and indenter tip. For Quality Control of Hard Coatings, any modification of the deposition process, coming from the substrate or the coating, can be detected very precisely with the scratch testing method. It is important to pinpoint that the sample, i.e the mechanical system tested, corresponds to the combination coating/substrate and the results will be highly dependent of their combined properties: as an example (not exhaustive), the thickness of coating influences the residual stresses in the coating, which would as a consequence modify the critical loads measured by scratch testing. The hardness and elastic modulus of the substrate influence also the elastic deformations created in the coating.

As a consequence, the critical load values could be shifted to higher values when the hardness of the substrate is increased. The thickness of coating has also an influence but more to a logarithmic scale. Therefore, the samples must be considered as a mutual combination of coating with substrate. Tribometer and indentation testing instruments provide information on the PVD or CVD coating mechanical properties. But none of these methods would give meaningful information on the control quality of the deposition process and the parts performances. Therefore scratch testing, by measuring not only the coating adhesion but also the mechanical strength of the coating-substrate system, represents the most valuable QC tool for the reproducibility of the deposition process.

References

ASTM C1624-05 (2015) Standard Test Method For Adhesion Strength And Mechanical Failure Modes Of Ceramic Coatings By Quantitative Single Point Scratch Testing.

ISO 20502 (2005-reviewed and confirmed in 2019) Fine ceramics (advanced ceramics, advanced technical ceramics) – Determination of adhesion of ceramic coatings by scratch testing.

The Scratch and Indentation Tester Has More To Offer

Learn more about our Indentation and Scratch Tester, the SMT-5000.

Need Versatile Scratch and Indentation Testing?

Take a look at the Multi Function Tribometer, the MFT-5000.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved