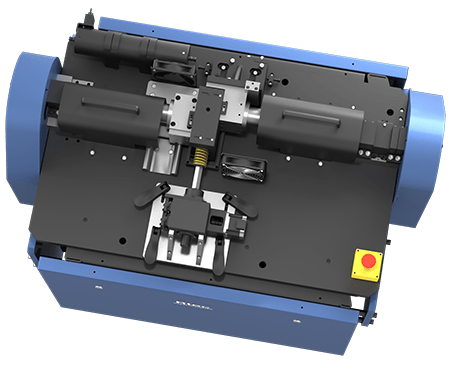

Twin Roller Tribometer Overview

Main Features:

- Pure rolling, pure sliding, combination of rolling sliding

- Servo Controlled Load control

- Environmental control

- Versatile to mount several kinds of samples

- In-line 3D optical inspection

- In-line friction and wear

Why Dual Roller Tribometer? Rolling-contact fatigue (RCF) is failure or material removal caused by the surface alternating stress field. The failures are typically driven by crack propagation. The extent of failure or the mechanism depends on a number of factors. For example, lubricant cleanliness, material quality, and roughness. With advent of high speed trains, EV vehicles, and turbines, rolling contact fatigue testing is very important for preventing the failure of components.

Rtec-Instruments’ TwinRoller-3000 is an ideal twin roller machine for the study of traction, wear, and rolling contact fatigue under various combinations of rolling sliding ratios. With an open platform architecture that allows easy access and use, the tester comprises of two high torque independently controlled servo motors. The force is applied using electro servo drives. Fully automated programs and advance controllers allows for high repeatability and precision measurements.

Need help or have a question?

Features

Rtec Instruments’ two roller tribometer has several key design features that makes it the only commercially available tester to run a wide set of conditions and in-line inspection on the same platform. With high data acquisition of 200 Khz, the TwinRoller-3000 obtains high precision measurements.

Closed-loop Patented Force Sensor

Capacitive and strain gauge force transducers work across a wide range with no drifts. Real-time servo closed-loop force control. This allows the creation of automatic torque vs load and speed curves.

Precise Temperature Control

Closed-loop temperature controller. From -35 to 150°C

In-line Torque Measurement

Self aligned in-line high resolution torque sensors to quantify surface dynamics in real-time.

Accurate Determination of Failures

The twin roller tribometer can accommodate various in-line monitoring sensors to quantify real-time surface dynamics. (acoustic, electrical, etc.)

Rotary Motion

High power, high speed, real-time speed control allows for repeatable data generation.

Integrated In-line Imaging

Image surface with nm resolution without taking sample out of the chamber. Integrated 3D profilometer to look at surface change during the test.

Many Configurations Are Possible

Rtec Instruments’ Twin Roller Tribometer comes in several application specific configurations.

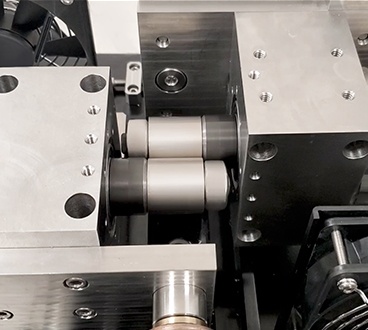

Rollers Under Load

Wider range of roller diameters can be accomodated on the same platform.

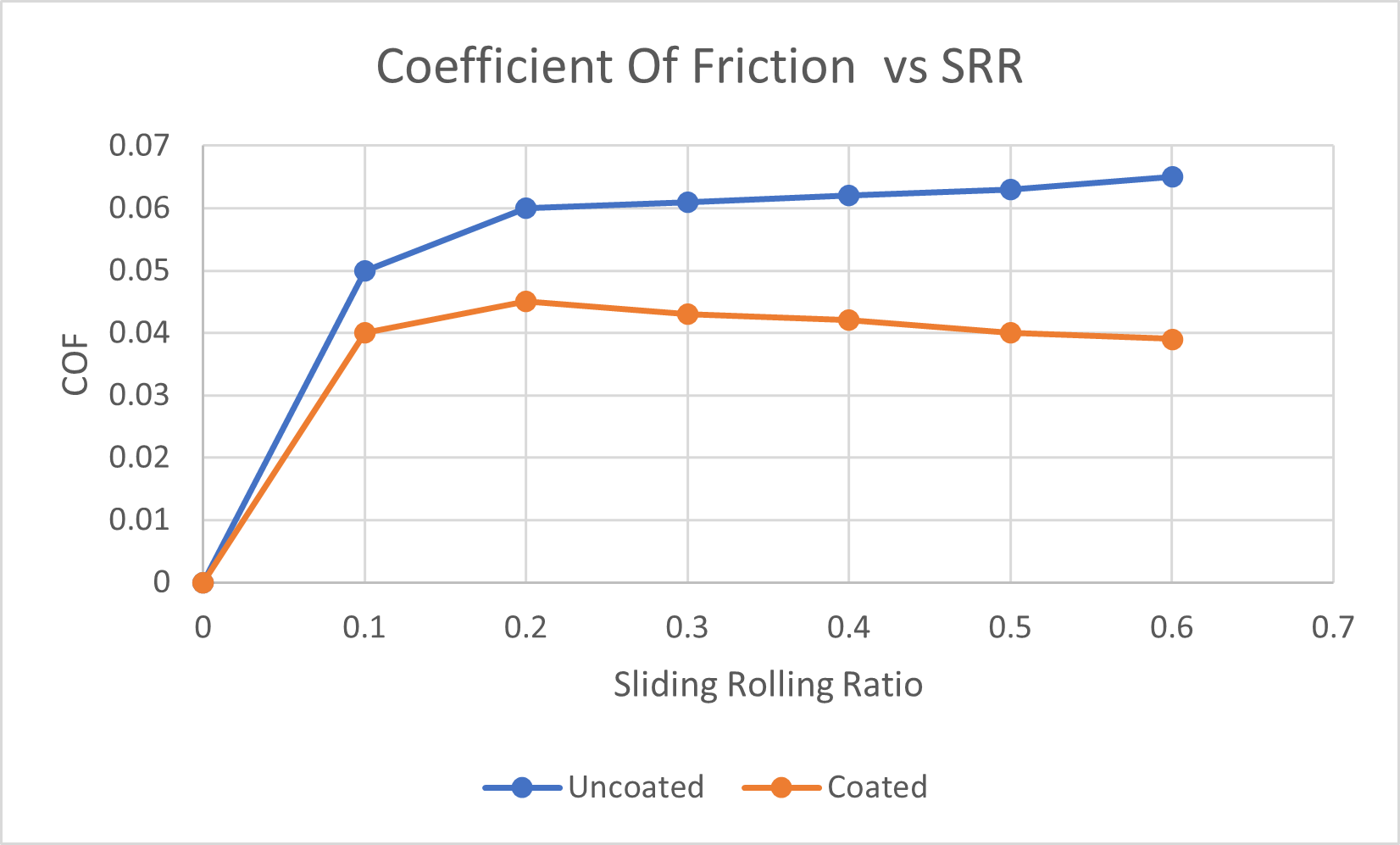

Twin Roller Tribometer Test Data

Data shows coefficient of friction results from rolling contact fatigue setup. The surface treatments were done on one sample. Data shows which improvement in RCF life after the thermal spray coating application.

Sample 1 – uncoated

Sample 2 – thermal spray coating

- 500 N force

- SRR from 0 to 0.6

- Temperature 70°C

Two Roller Machine Solution

The twin roller machine is used extensively across a wide range of industries and applications. It’s used to analyze lubricants, contact fatigue life, and electrical contact resistance under various slip ratios.

-

Space

-

Lubricant

-

Automotive

-

Railways

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved