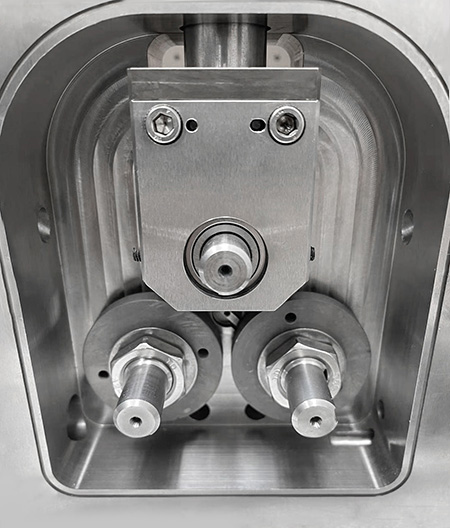

Micropitting Rig Overview

Main Features:

- Load up to 5000 N

- Real-time force and speed control

- Run millions of cycles in a short period of time

- Lubricant temperatures up to 150 °C

- Standard torque range up to 60 Nm

- SRR (slide–roll ratio) 0 to +/- 200%

- Center pin 4 m/s, outside three rollers 18m/s

Why the Triple Disc Machine? Three-disc rolling instruments are designed to assess and evaluate the resistance of materials or coatings to various types of wear. These types of wear include rolling contact fatigue (RCF), pitting, and micro-pitting. By simulating real-life conditions using different rolling or sliding combinations, contact pressures, and lubrication regimes, researchers and product developers explore and understand the behavior of materials, coatings, and lubricants under different operating conditions.

Rtec-Instruments’ MPT-3000 Micropitting Tester is an ideal triple roller contact machine for studying traction, wear, and rolling contact fatigue under various combinations of rolling sliding ratios. The open platform architecture allows for easy access to the samples and setup. In addition, the fully automated and advanced controllers allow for high repeatability and precision measurements with the broadest test range in load, temperature, and speed. Quickly develop high-quality materials, coatings, and lubricants with automatic and repeatable failure and comparative analysis. In addition, the MPT-3000 helps ensure that manufactured components, such as gears, bearings, and other high-contact surfaces, meet the required standards and performance criteria fast and efficiently.

Need help or have a question?

Watch the MPT-3000 Micropitting Rig in Action

MPT-3000 Micropitting Rig Features

Rtec Instruments’ micropitting rig has several key design features, making it the only commercially available tester to run a broad set of conditions and in-line inspection on the same platform. With pure sliding, pure rolling, and 0 to +/- 200% sliding/rolling ratio (SRR), the MPT-2000 obtains high precision measurements.

Closed-loop Patented Force Sensor

Measure force with the capacitive force transducers that work across a wide range with no drift—real-time servo closed-loop force control. Create automatic torque vs. load and speed curves.

Precise Temperature Control

Closed-loop temperature controller with a range of -35 to 150 °C.

In-line Torque Measurement

Self-aligned in-line high-resolution torque sensors for smooth rotation and a wide range of testing.

Accurate Determination of Failures

The MPT-3000 micropitting tester accommodates various in-line monitoring sensors to quantify real-time surface dynamics, including acoustic emission, electrical resistance, and potentiostat.

Rotary Motion

High power, high speed, and real-time speed control allow for repeatable data generation. Achieve a rolling velocity of up to 4 m/s at 0 pure rolling and an outside roller speed of 18 m/s at 6500 RPM.

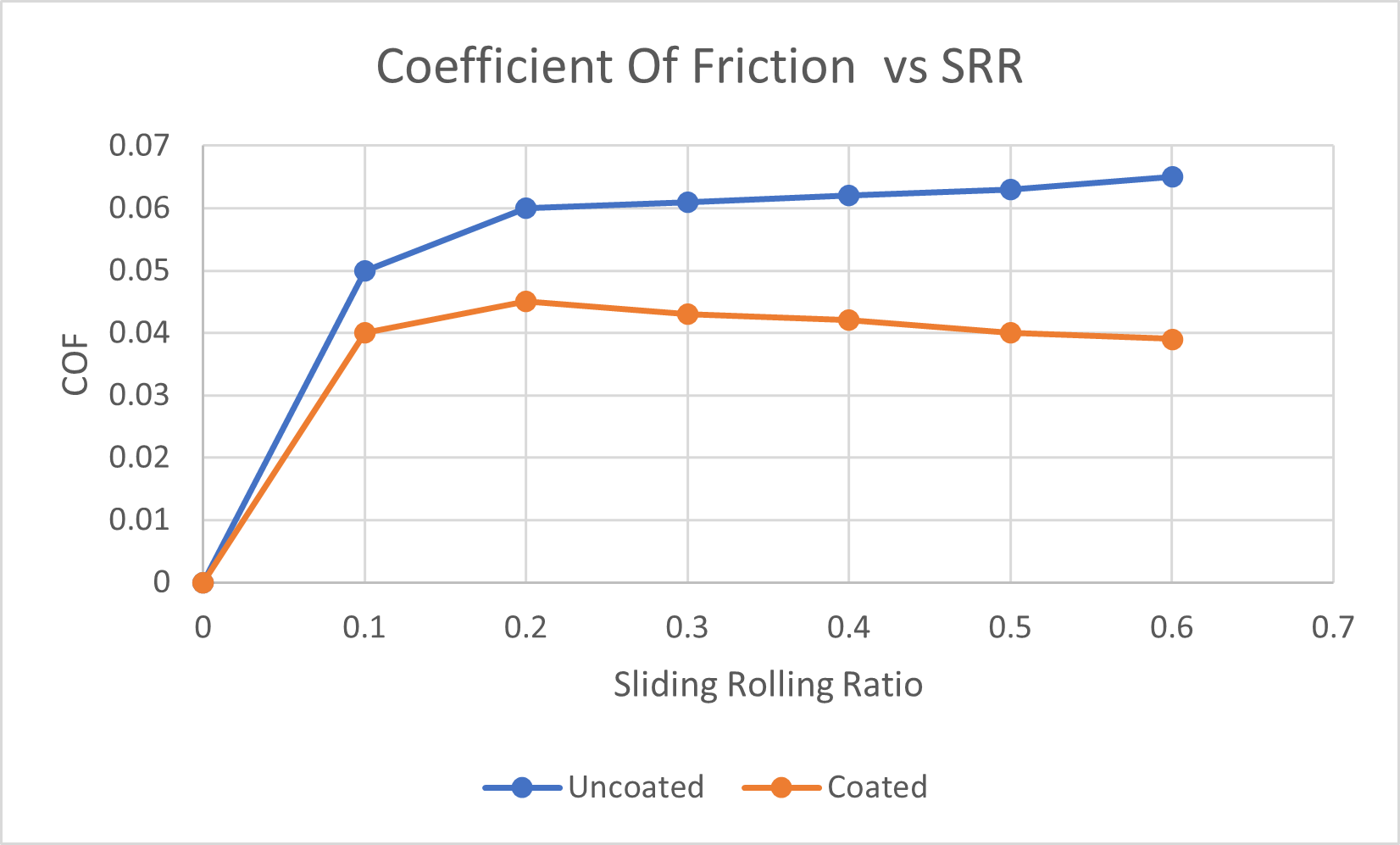

Micropitting Testing Data

The data on the left shows the coefficient of friction results from a three-disc rolling contact fatigue setup. Surface treatments were done on one sample. This data illustrates which improvement in RCF life after the thermal spray coating application.

Sample 1 – uncoated

Sample 2 – thermal spray coating

- 500 N force

- SRR from 0 to 0.6

- Temperature 70°C

Micropitting Testing and Surface Fatigue Solution

Evaluating rolling contact fatigue, pitting, and micropitting are essential for assessing the performance and durability of materials, coatings, and lubricants. The MPT-3000 triple-disc machine provides micropitting testing, analysis, and insights into wear and surface damage. Compare samples under controlled conditions for various applications and industrial uses.

-

Gears and gearboxes

-

Automotive industry bearings, transmission systems, and sustainable materials and lubricants

-

Power transmission industry systems and roller bearings

-

Industrial cyclic operations

-

Renewable energy wind turbines

-

Aerospace industry research of gears, bearings, and engine parts

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved