Watch Rtec-Instruments Lubricant, Oil, and Grease Testing in Action

Delivering fast and accurate friction and wear data you can trust to reduce mechanical failure, extend component life, and develop eco-efficient materials — all on one versatile platform.

Why Advanced Lubricant Testing Matters?

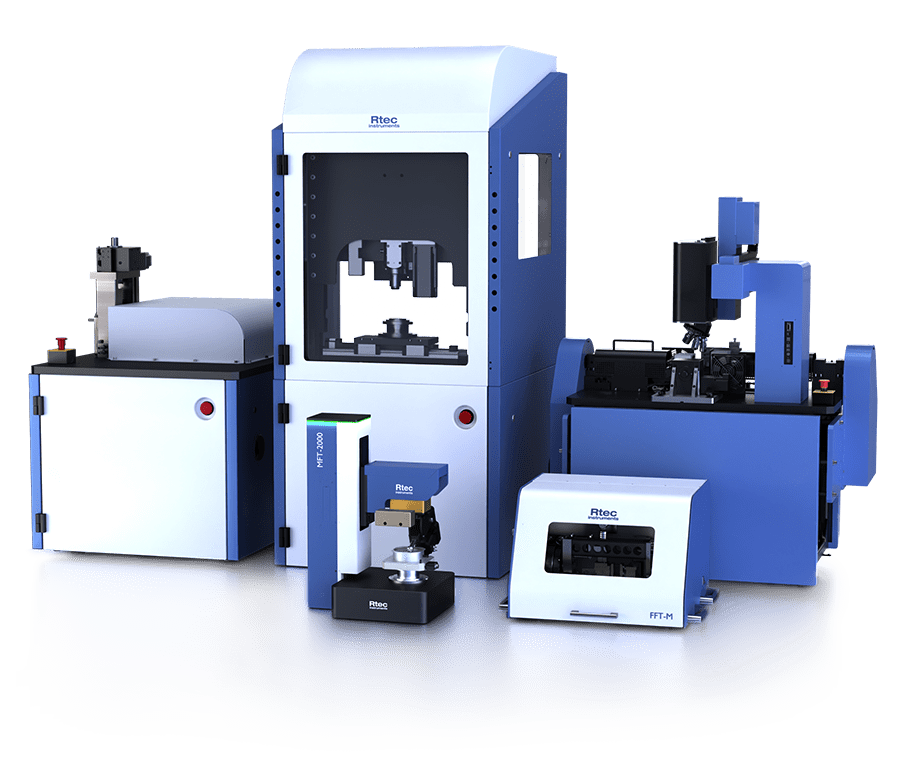

Our cutting-edge testing solutions are built with preventive monitoring at the core. We empower industries to assess, optimize, and extend the lifespan of materials, reducing waste and environmental impact. Our advanced testers and solutions include:

Multi Function Tribometers: Understand friction, wear, extreme pressure and lubrication on a microscopic level, as our instruments and combined 3D imaging analysis enable the development of sustainable materials.

Traction Machines: From renewable energy to transportation, our two and three roller testers provide the lubricant testing solutions that foster innovation and align with your environmental goals.

Measure

Friction, wear, lubrication regimes with multi‑sensing

Optimize

Formulations and components using comparable, repeatable data

Sustainability

Validate eco‑friendly lubricants and additives with lifecycle testing

Lubricating Tribology Overview

Main Features:

- Several ASTM, DIN, ISO Standards

- Up to 10000 N Load On the MFT-5000

- Environmental Control: -60 to 1200°C Chambers on MFT-5000, up to 150°C on rolling platforms

- Electrified Testing: DC mode, AC mode, with Impedance, spark studies

- Stribeck Curves

- Rotary, Reciprocating, Block on Ring, Tapping Motions

- Twin Roller and Micropitting (Rolling Sliding Pitting)

Help prevent mechanical failure with Rtec Instruments’ lubricant triblogy testing equipment. Precision testing drives innovation in sustainable lubrication. Rtec Instruments’ tribology platforms deliver high‑accuracy friction, wear, and lubricity data for lubricants, greases, oils, solid coatings, and additives — helping you reduce mechanical failure, extend component life, and design more efficient, eco‑friendly systems. Run several ASTM, DIN, ISO standards and customized tests in controlled environmental conditions, including humidity, temperature, and loads from mN to 10,000N on the MFT-5000 platform. Some examples of the Rtec tribometer lubricant testing include, HFRR, Timken, SRV, 4 Ball, Tapping Torque, and so much more.

Need help or have a question?

Learn More About Our Tribometer Platforms

Lubricant Tribology Platforms

Learn more about our versatile tribometer platforms that provide friction, wear, and surface properties of various materials under a multitude of environments and electrified testing conditions.

Lubricants, Oil, and Grease Testing For Any Application

At Rtec-Instruments, we’ve built the most versatile MFT-5000 tribometer to leave nothing to be desired and every lubricant test is achievable. Click to learn more about each test that the MFT-5000 provides.

Learn more about our lubricant, oil, and grease testing platforms.

The Universal MFT-5000 Tribometer

Take a closer look at the Multi Function Tribometer and its extensive range of testing setups.

Micropitting Rig

Learn more about the MPT-3000 Micropitting Tester’s cutting-edge features and applications.

Twin Roller Tribometer

Explore how the Twin Roller Tribometer revolutionizes friction and wear testing with its unique dual-roller configuration.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved