Lubricants

Rtec Instruments provides several ASTM, DIN, ISO standard and customized tests to evaluate friction, wear, lubricity, and tribological properties of lubricant, oil, grease, additives, solid coatings, and much more. Lubricant testing in controlled environmental conditions are available. This includes humidity and extreme temperatures with loads from mN to 12,000N.

Lubricant Industry Solutions We Offer

Analyze and assess the performance of lubricants with a our versatile testing instruments.

Oil, Lubricant, Additives, Grease

Test oil, lubricants, additives, grease using several ASTM, DIN, ISO standards. Carry out standard and customized tests across a wide range of load, speeds, and test temperature. Rotary, block on ring, mini traction testing, 4 ball, SRV, HFRR, linear reciprocating, and EP wear modes are available.

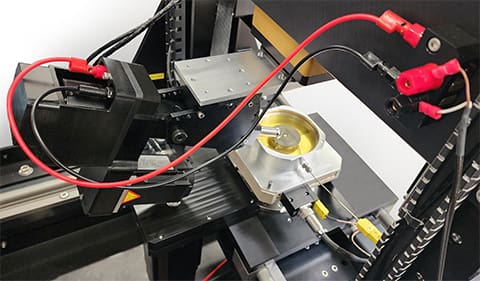

Electric Vehicle Lubricant Screening and Development

Rtec Instruments offers cutting-edge solutions for electric vehicle lubricant testing to meet the growing demands of the EV industry. Compare lubricant regimes and precisely measure impedance against varying linear velocities with in-depth testing of wear, friction, and lubrication under high loads, speeds, and temperatures. Ensure your EV lubricants can withstand the unique stresses of electric powertrains. With Rtec’s advanced capabilities, manufacturers can optimize EV components’ performance, efficiency, durability, and longevity.

Engine

Rtec Instrument offers several solutions for engine related tests to measure friction, wear, adhesion, roughness, fretting, and more. Study piston ring liner friction and wear at engine speed on a lab scale. Test engine additives with our HFRR and SRV test setup. Study DLC and other coating adhesion using our scratch test setup. Study fretting failures of engine components due to constant vibrations.

Fretting

Fretting wear occurs when two contacting surfaces experiencing oscillatory displacement of small amplitude.

Rtec Instruments provides voice coil based fretting tester that can control stroke from 10 microns to 4 mm, and frequencies up to 300 Hz. Test the fretting failure under controlled environmental conditions.

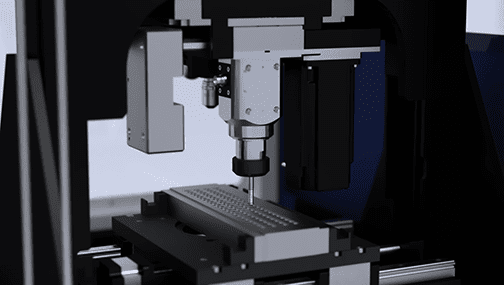

Metal Working, Cutting tools

Characterize metal working, forming fluids, additives, and lubricants. Rtec Instruments offers tapping torque test, CNC simulator, and cutting tool test setups that simulate actual life processes under lab conditions.

Bearings

Characterize bearings, grease, coatings, washers, rings, and shafts. Wide loads, speed, and environmental controlled conditions. Rtec Instruments block on ring test setup allows several ASTM, DIN, ISO and non standard tests .

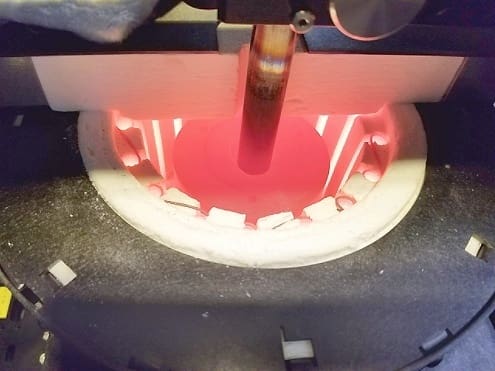

High Temperature

Characterize effect of temperature (up to 1200°C) on tribological properties of grease, coatings, lubricants, and surfaces. Run standard ASTM, DIN, ISO tests, or perform custom tests on the versatile multi function tribometer.

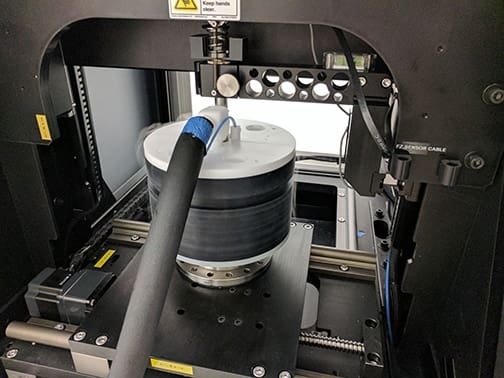

Low Temperature

Low temperature tribology testing chambers offer friction, wear studies from -120 °C (liquid Nitrogen cooled). Perfect for space research, EV vehicles, power plants, and low temperature friction and wear analysis for coatings, materials, and components. Run several common rotary tests at cryogenic levels, such as low temperature ball on disk tribometer and low temperature pin on disk tribometer tests.

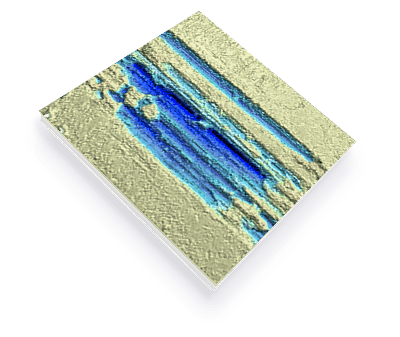

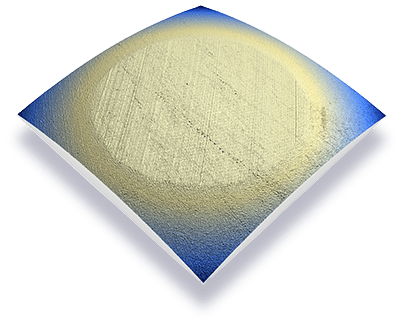

3D Imaging

Study surface roughness, film thickness, and surface profile with our universal profilometer. The profilometer can be a stand-alone instrument or combined on the tribometer platform. These provide surface change vs time during friction and wear analysis.

Universal profilometer combine 4 imaging modes in one head to characterize a wide range of testing surfaces used in lubricant industry. Image any surface with ease with this combination of imaging modes – transparent, flat, dark, flat, curved, and more.

Surface Modification, Solid Lubricant, Coatings

Surface modifications are used to alter surface friction, wear, and mechanical properties. Study correlation between lubricant, grease, additives, surface modifications, or solid coatings using several provided solutions. Study wear, friction, adhesion, and hardness under various controlled environmental conditions.

Custom Industrial Development

Rtec Instruments offers several industry application solutions. We are always keen on helping the industry to get solutions to the problems they encounter. Few development examples include:

Brake Screening, Superlubricity, Compressor 200 psi test, Rapid timken tester, Rapid 4 Ball tester, Thermal Spray coating tester, Optical lens testing, and much more.

See Our Lubricant Industry Solutions In Action

Watch as we demonstrate how our instruments can fulfill the needs of lubricant research and quality control.

Need Versatility?

Need Fretting?

Need Indentation and Scratch Testing?

Learn more about our Indentation and Scratch Tester, the SMT-5000.

Need HFRR Testing?

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved