Schmierstoffe

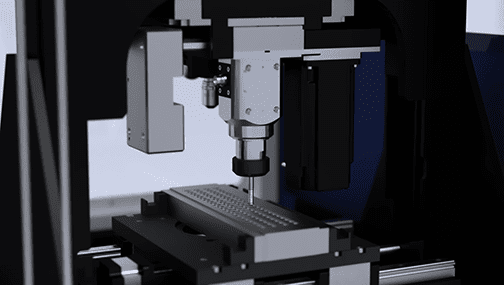

Rtec Instruments provides several ASTM, DIN, ISO standard and customized tests to evaluate friction, wear, lubricity and tribological properties of lubricant, oil, grease, additives, solid coatings, and more.

Lubricant Industry Solutions We Offer

Oil, Lubricant, Additives, Grease

Electric Vehicle Lubricant Screening and Development

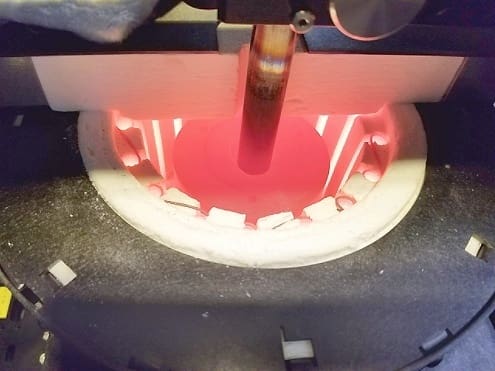

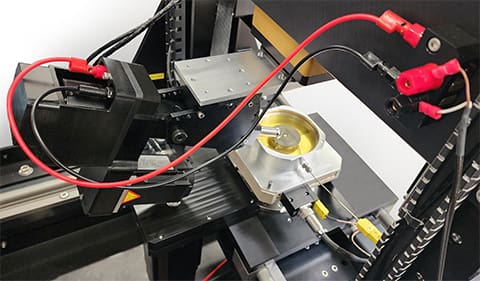

Rtec Instruments offers cutting-edge solutions for electric vehicle lubricant testing to meet the growing demands of the EV industry. Compare lubricant regimes and precisely measure impedance against varying linear velocities with in-depth testing of wear, friction, and lubrication under high loads, speeds, and temperatures. Ensure your EV lubricants can withstand the unique stresses of electric powertrains. With Rtec’s advanced capabilities, manufacturers can optimize EV components‘ performance, efficiency, durability, and longevity.

Engine

Fretting

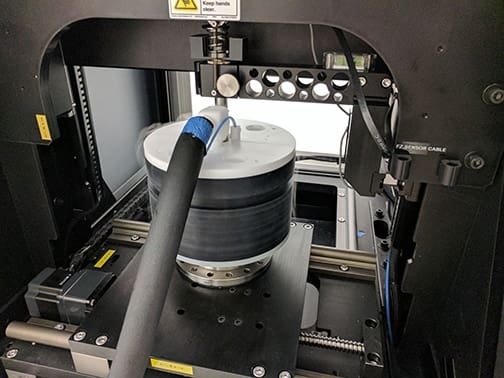

Rtec Instruments provides voice coil based fretting tester that can control stroke from 10 microns to 4 mm, and frequencies up to 300 Hz. Test the fretting failure under controlled environmental conditions.

Metal Working, Cutting tools

Bearings

High Temperature

Low Temperature

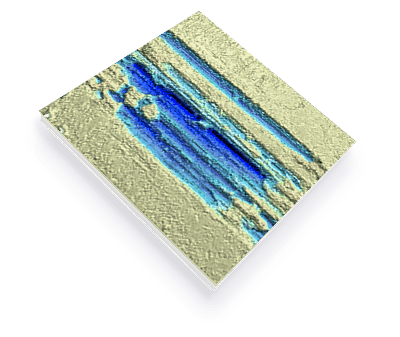

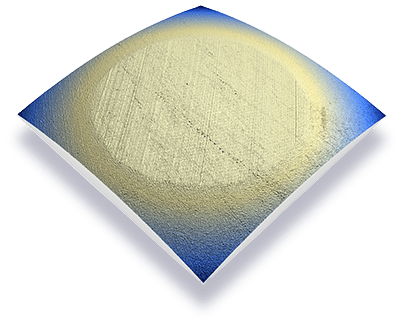

3D Imaging

Universal profilometer combine 4 imaging modes in one head to characterize a wide range of testing surfaces used in lubricant industry. Image any surface with ease with this combination of imaging modes – transparent, flat, dark, flat, curved, and more.

Surface Modification, Solid Lubricant, Coatings

Custom Industrial Development

Brake Screening, Superlubricity, Compressor 200 psi test, Rapid timken tester, Rapid 4 Ball tester, Thermal Spray coating tester, Optical lens testing, and much more.

See Our Lubricant Industry Solutions In Action

Need Versatility?

Need Fretting?

Need Indentation and Scratch Testing?

Need HFRR Testing?

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved