Cutting Tool Tribometer Overview

- Multiple test setups on same platform

- Real component testing and quick screening

- Several in-line sensors for advanced analysis

- In-line 3D Profilometer to look at surface finish

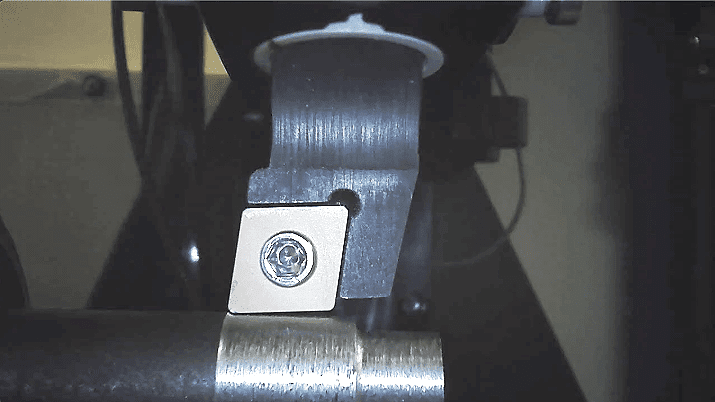

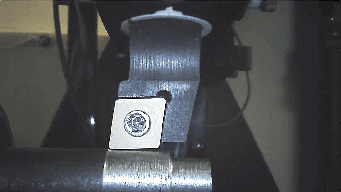

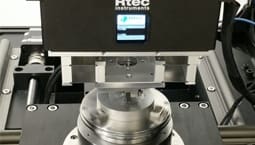

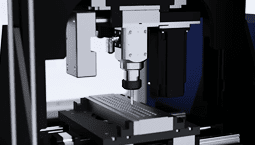

Why Study? Machining is shaping materials into useful forms by removing the material. The cutting tool contacts with the work piece and either the tool, the work piece, or both while in motion. Cutting tool wear, final surface finish, cutting rate, metalworking fluids, additives, emulsifiers effect reliability and cost-effectiveness of the entire process. Study tribology and mechanical properties to improve machining and cutting tool process. Rtec Cutting Tool Tribology solution comes with various test modules that mounts on the same platform. The test setups allows characterization of cutting inserts, tools, taps, drill bits, fluids, materials, coatings, process parameters, and many more. For a quick screen of the entire process or for research and development, we use this setup.

Brauchen Sie Hilfe oder haben Sie eine Frage?

Learn More About The MFT-5000 Platform

The MFT-5000 Tribometer

Learn more about the versatile MFT-5000 tribometer that provides friction, wear, and surface properties of various materials under a multitude of environments and testing conditions.

Watch Cutting Tool Testing in Action

Test Setups On Same Tester

Cutting Tool Simulation

Scratch Adhesion and Hardness

Spiral Wear Test

Tapping, Drilling, Cutting

Solution To

-

Cutting Tools

-

Hard Coatings

-

Lubricants, Additives

-

Metal Working Fluids

The MFT-5000 Has More To Offer

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved