Arzneimittel

Pharma Manufacturing Solutions We Offer

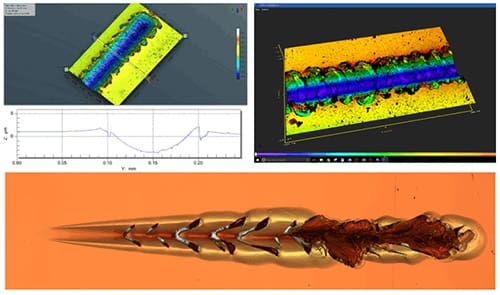

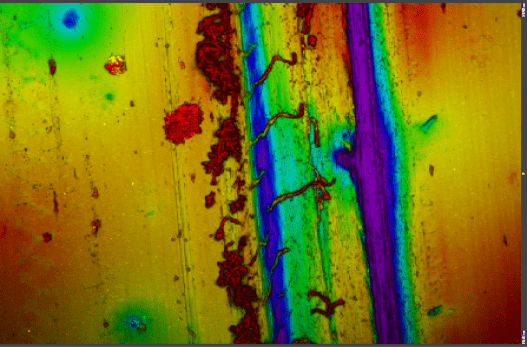

Scratch Adhesion, Hardness

Study scratch adhesion, scratch hardness, scratch resistance at nano, micro and macro scale. In-line integrated 3D profilometer creates 3D stitched images to comprehensively and conclusively characterize the coating failures.

3D Imaging Pharmaceutical Solutions

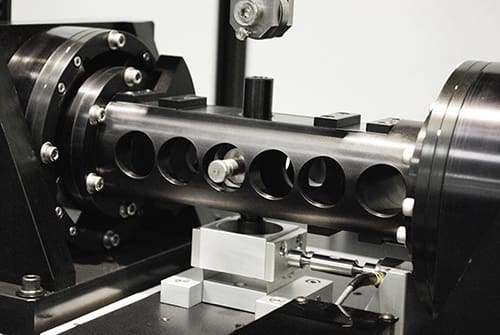

Fretting

Rtec Instruments provides unequaled specifications for stroke and frequency control for fretting evaluation. Controlled stroke from 5 microns and frequency up to 500 Hz frequency make it an ideal fretting wear tester for both industry and university research.

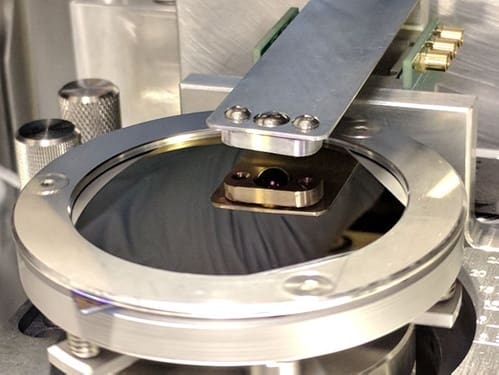

Friction, Wear

Rtec Instruments provides measurement solutions for both static and dynamic coefficient of friction. We provide a wide test range that simulate real-life process. In addition, the add-on integrated 3D profilometer analyzes tablet surface change vs time.

Pharmaceutical Quality Control In Action

Brauchen Sie Vielseitigkeit?

Need Fretting?

Need Indentation and Scratch Testing?

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved