Biomaterialien

Rtec Instruments provides several ASTM, DIN, and ISO standards and customized solutions for the biomaterials industry. Analyze coatings, teeth implants, contact lenses, stents, prostheses, implants, bovine serum, and more.

Biomaterial Solutions We Offer

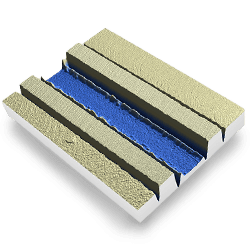

Scratch Adhesion, Resistance

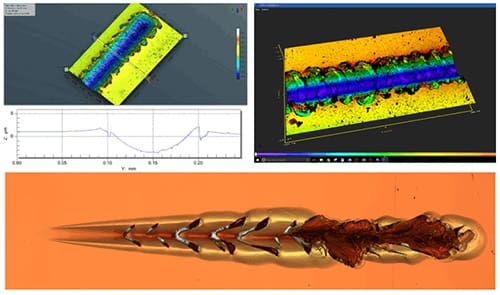

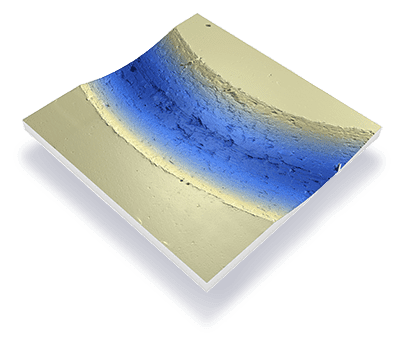

Study scratch adhesion, scratch hardness, scratch resistance at nano, micro, and macro scale. An In-line integrated 3D profilometer creates 3D stitched images to comprehensively and conclusively characterize the coating failures.

Fretting

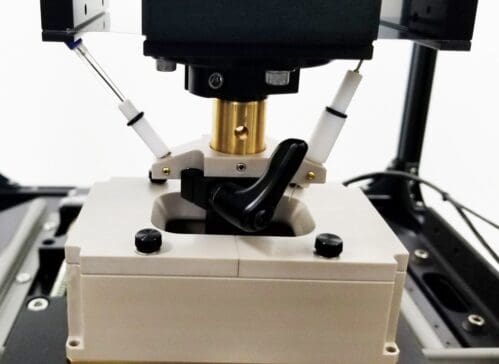

Novel materials and coatings for replacing and repairing human body parts, various medical devices, and other standard medical equipment are growing in the biomaterial industry. To study degradation due to fretting, wear, and corrosion, Rtec Instruments provides unequaled specifications for fretting testers. Testers include controlled stroke from 5 microns to several mm and up to 500 Hz frequency across controlled environmental conditions (temperature and liquids).

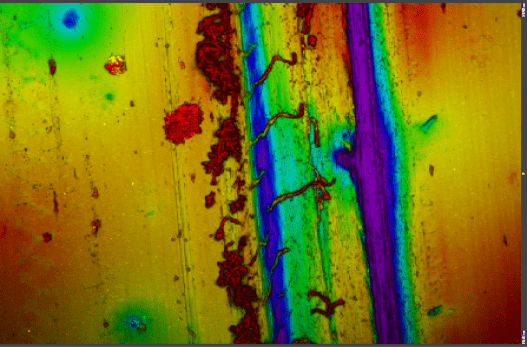

Corrosion

Medical devices in humans use metallic biomaterials and coatings more than any other family of materials. The corrosion resistance of materials affects their functionality, durability, and is a prime factor governing biocompatibility.

Study the effect of corrosion of biomaterials, coatings and components durability, adhesion, hardness, fretting, wear resistance, friction, and more using several available testers.

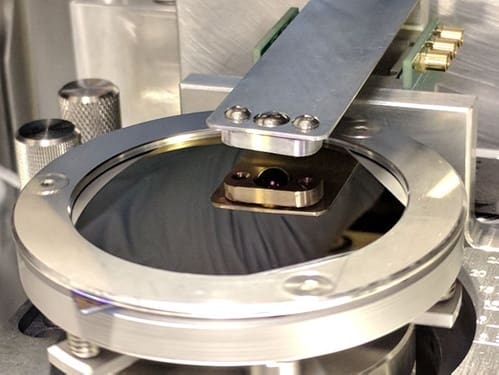

Dental

Rtec Instruments provides several biomaterial quality control and research solutions for the dental industry. Study life of dental materials, implant torque strength, wear between two tooth surfaces, effect of toothbrush on dental materials, and image surface change vs time. Test one or multiple samples at the same time. The profilometer provides tooth surface imaging with ease.

Catheters

Catheters require rigorous testing to ensure lubricity performance, as it is a critical factor affecting insertion force, push force/ navigation force, and removal force.

Rtec-Instruments’ modular Multi Function Tribometer with patented capacitive force sensors provides multiple test setups to mimic clinical use while tracking catheter delivery through vitro fixtures. Its high-resolution 3D profilometer and force characterization produce friction mapping to analyze the overall performance of the catheter.

Adhesion

Polymers

Advances in the production of well-defined and optimized polymers play a central role of polymers in functional biomaterials. Commodity synthetic polymers are widely used as contact lenses, intraocular lens materials, microspheres as drug delivery reservoirs, and polymer scaffolds for tissue engineering.

We offer a wide range of biomaterial industry solutions for bio-polymers. Test surface and finish components by evaluating friction, durability, roughness, and topographical data, multi-layer film thickness, and scratch resistance.

Biomaterial 3D Imaging

Friction and Wear

Understanding biomaterial friction is of increasing importance due to the various new applications of industries, such as healthcare, biomedical, food, personal care, and the incorporation of soft materials into technology.

Perform tribology, friction, and wear studies under a wide test load range, and motion. All while testing under a variety of controlled environmental conditions, such as liquid, temperature, and corrosion. Test coatings, materials, and components (contact lenses, optical glasses, tooth, hip joint, stents, sutures, implants, tissue, skin, valves, connectors) with ease. Combine the data together with our in-line integrated 3D profilometer.

Biomaterial Solutions In Action

Need Versatility?

Need Fretting?

Need Indentation and Scratch Testing?

Need 3D Microscopy?

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved