Aerospace

Rtec Instruments provides several ASTM, DIN, ISO standard and customized test solutions to evaluate aerospace coatings, materials and components under extreme environment conditions. This includes cryogenic, high temperature and vacuum.

Aerospace Solutions We Offer

So many choices. No wrong answers.

Thermal Spray Coatings

In the aerospace industry, there are hundreds of key components that use thermal sprayed coatings. Rtec Instruments offers testers to measure coating adhesion, wear resistance, fretting resistance, friction, durability, hardness, roughness, and many more.

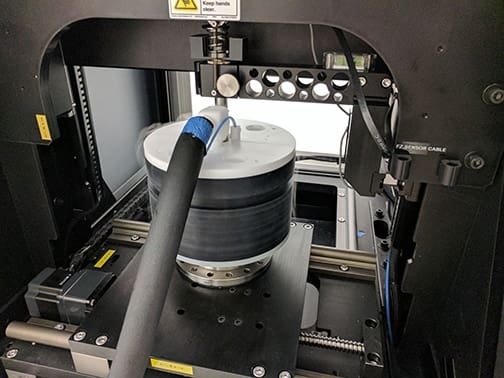

Fretting and Wear Resistance

Studying fretting, coatings, and materials in the aerospace industry is critical for new technology, space exploration, aging aircrafts, structural integrity, riveted aircraft structure, aircraft engines, aluminum alloys, and titanium alloys. Rtec Instruments provides unequaled specifications for stroke and frequency control for fretting evaluation. Controlled stroke from 5 microns and frequency up to 500 Hz frequency across a wide temperature range makes it an ideal fretting wear tester for both industry and university research.

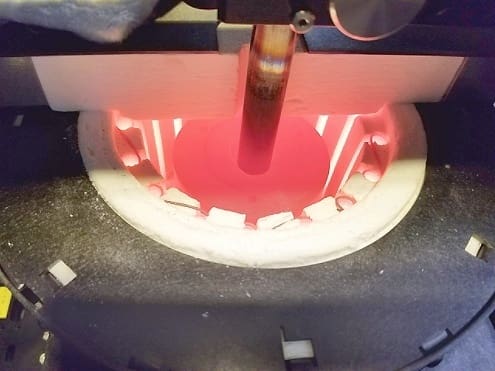

High Temperature

Perform high temperature materials testing up to 1200 °C. Testing condition can mimic real-life scenarios, allowing users to generate data essential for solving real-life problems. Characterize hot hardness, friction, fretting wear, coating adhesion, and much more under controlled atmosphere conditions. These include inert gas, vacuum, multiple sample stages, and more.

Low Temperature – Cryogenic

Characterize friction, wear, and adhesion of materials and coatings under in cryogenic conditions up to -120°C using liquid nitrogen. Test under vacuum or non vacuum conditions.

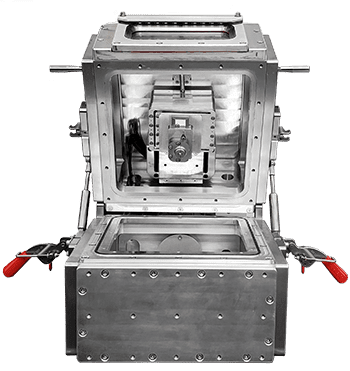

Vacuum Conditions

Test coatings and materials for space and aerospace industry under vacuum and controlled temperature. Measure friction, wear, adhesion, and durability under vacuum up to 10-7 torr. Simultaneously control environmental conditions, from -120 °C to 800 °C.

Abrasion, Erosion Resistance

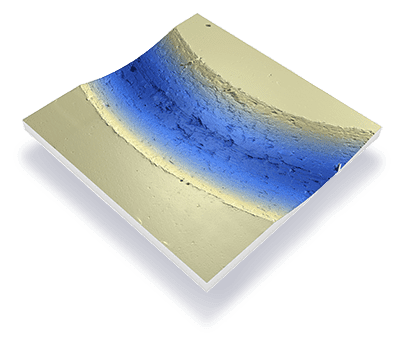

Rtec Instruments provides several options for abrasion and erosion resistance testing. The Air Jet Erosion Tester, AJ-1000, performs repeated impact tests using a jet of gas loaded with abrasive particles to measure erosion of samples up to 900°C. The tribometer allows abrasion resistance testing in several modes across a wide load, speed, and temperature range. Measure roughness and the surface profile of rough test surfaces using confocal spinning disk technology on our profilometer.

3D Imaging

Combine 4 imaging modes in one head. It requires only one mouse click to alternate between the different imaging modes. Image any surface with ease – transparent, flat, dark, flat, curved, and more.

See It In Action

Watch as we demonstrate how our instruments can fulfill all of your applications.

Need Versatility?

Take a closer look at the Multi Function Tribometer.

Need Fretting?

Check out our FFT Fretting Testers Series

Need Indentation or Scratch Testing?

Learn more about our Indentation and Scratch Tester, the SMT-5000.

Need An Erosion Tester?

Check out the AJ-1000 product page.

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved