Home > Tribometers > Anwendungen >

Übersicht: Nanotribologie

Merkmale:

- Auflösung in Mikro-Newton

- Bewährte Technologie zur Messung von COF = 0,001

- Patentierte kapazitive kraftsensoren

- Temperatur, Vakuum und inerte Atmosphäre

- Patentiertes Inline-3D-Profilometer

Rtec Instruments bietet ein hochmodernes Nano-Tribometer für die Durchführung von extrem niedrigen Reibungskoeffizienten und Druck in Tribologie. Patentierte Kraftsensoren mit vernachlässigbarer thermischer Drift sind das Herzstück dieses Nano-Tribometer-Moduls. Das Modul mit geringer Reibung kann bei kontrollierten Umgebungsbedingungen arbeiten.

Brauchen Sie Hilfe oder haben Sie eine Frage?

Erfahren Sie mehr über die Analyseplattformen

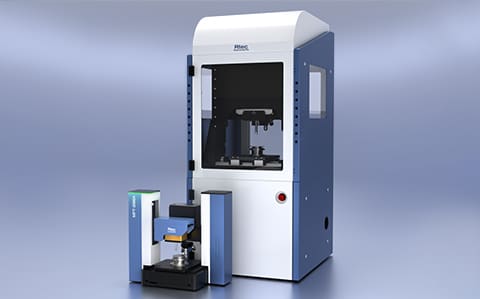

Die Tribometer der MFT-Serie

Entdecken Sie unsere MFT-Tribometer, die vielseitige Oberflächen- und Materialprüfungen ermöglichen.

Unübertroffene Kraftmesszellentechnologie

Patentierte kapazitive Sensoren

Neben einer unvergleichlichen Genauigkeit und Auflösung ermöglichen die Sensoren den Einsatz in verschiedenen Umgebungen.

Kapazitive Kraftaufnehmer

Höchste Auflösung durch hochsteife Konstruktion

Haltbarkeit

Ein einzigartiges Design verhindert eine Beschädigung des Sensors bei unsachgemäßer Handhabung

Zusätzlicher Piezo-Sensor

Optionaler, unabhängiger Piezo-Z-Aktuator für eine Z-Positioniergenauigkeit im Nanometerbereich.

Starres Design

Eine steife, hochstarre Konstruktion minimiert die Verkippung des Probenhalters.

Beisielhafte Nano-Tribologie-Konfigurationen

Die Nano-Tribometer-Technologie von Rtec-Instruments kann in verschiedene Konfiguration implementiert werden.

Supergleitfähigkeit einer 2D-Materialprobe

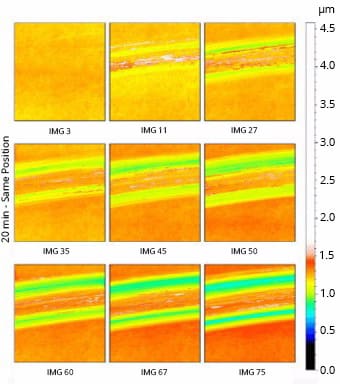

Testbegleitende Erstellung von 3D-Topographiekarten während des Versuchs

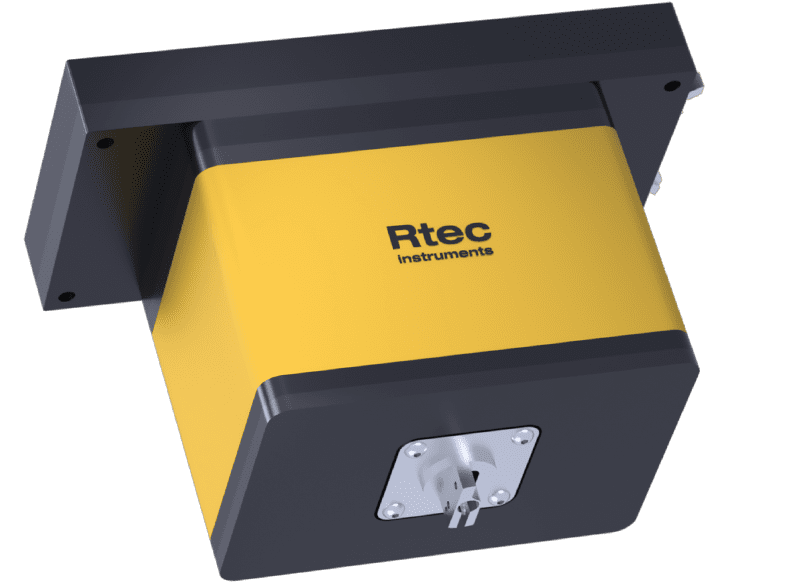

Vakuumkammer mit Nano-Tribometer und Inline-Profilometer

Zeitverlauf der Rauheit und des Verschleißvolumen mittels automatischer Inline-Bildgebung

Einfaches Korrelieren von Reibung, Verschleiß mit Topografieänderungen

Das integrierte 3D-Profilometer misst während des Tests automatisch die Oberflächentopografie der Verschleißspur, ohne dass die Probe aus dem Halter entnommen werden muss. Das Profilometer ist für nanomechanische Tests optimiert. Betriebsmodi, wie Konfokalmikroskopie, Dunkelfeldmikroskopie und Interferometrie ermöglichen eine Auflösung im Nanometerbereich. Die Veränderung der Topografie im Nanobereich ermöglicht ein umfassendes Verständnis der Nanotribologie und vom Ursprung des beobachteten Verschleißes. So berücksichtigt beispielsweise das anfänglich erfasste 3D-Bild Korngrenzen, Rauheit, Ausrichtung der Proben und andere lokalisierte Merkmale der Kontaktflächen. Der hochpräzise XY-Tisch ermöglicht es, die gesamte Verschleißspur automatisch zusammenzufügen (stitching).

Analyse

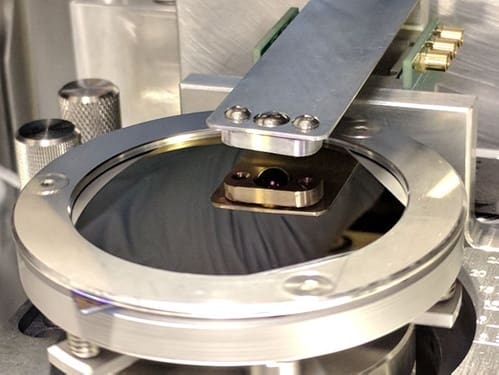

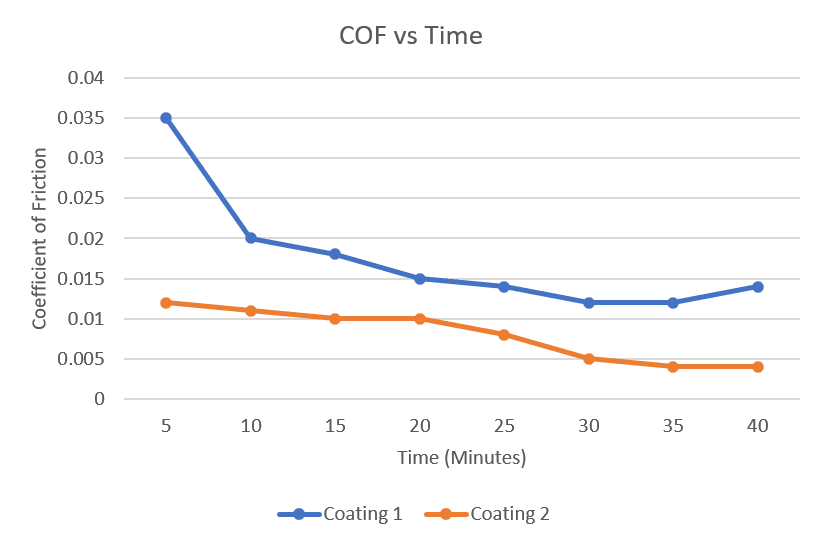

Ball-auf-Scheibe-Aufbau und die Versuchsdaten

Der Prüfaufbau

Die mit DLC beschichtete Kugel wird senkrecht zu den mit einer Dünnschicht beschichteten Wafer auf dem Drehmodul positioniert. Die universellen, oberen und unteren Probenhalter dienen zur Befestigung der Proben.

Versuchergebnisse

Die folgende Abbildung zeigt den Verlauf der Reibungszahl (cof) für zwei Beschichtungen bei einer Normalkraft von 50 mN und 400 U/min.

Warum ein AFM benutzen, wenn das Nanotribometer viel mehr bietet?

Installieren Sie gleichzeitig eine Vielzahl von Proben (unterschiedliche Größe und Geometrie) für verschiedene Anwendungen für extrem geringer Reibung. Untersuchen Sie die Reibungseigenschaften auf atomarer Skala.

Aufgabenstellung

Derzeit werden die meisten Messungen der nanoskopischen Reibung mit einem AFM durchgeführt. Die Prüfung mit einem AFM birgt jedoch einige Herausforderungen, da zählen:

- Kalibrierung der AFM-Spitzen zur Messung der Reibung

- Nicht wiederholbare Biegung der AFM-Spitzen

- Es kann nur eine geringe Druckkraft ausgeübt werden

- Nur ein kleiner Bereich der Probe steht für die Prüfung zur Verfügung

- Begrenzte Kontrolle der Umgebungsbedingungen

Die Lösung

Dieses Tribometer für niedrige Reibung kann mit hochpräzisen Sensoren geringe Reibung und sehr wenig Verschleiß über einen breiten linearen und rotatorischen Geschwindigkeitsbereich (10.000 U/min) messen. Da die Verschleißrate unter diesen Bedingungen vernachlässigbar ist, ist ein Inline-3D-Profilometer sehr nützlich, um Daten zu liefern, ohne die Probe zu entfernen. Diese einzigartige Kombination ermöglicht die Untersuchung des Verschleißvolumens und der chemischen Eigenschaftsänderungen der Verschleißspur über der Versuchszeit.

Die Vorteile

- Branchenführende, hochauflösende und robuste Sensoren für genaue, zuverlässige und wiederholbare Messungen, ohne dass alle paar Versuche eine Kalibrierung erforderlich ist.

- Im Vergleich zum AFM können wesentlich größere normalkräfte ausgeübt werden.

- Mikro- und Makroskalenproben für eine umfassende Charakterisierung von Beschichtungen.

- Kontrollierte Umgebungsbedingungen (hohe Temperatur, Vakuum, Inertgas, Wasserstoff)

- 3D-Bildgebung für die automatische Analyse von Verschleißspuren.

Die Lösung für

Die Nano-Tribologie-Aufbau wird für verschiedene Anwendungen und Industrien eingesetzt:

-

Hableiterindustrie

-

2D-Materialien

-

Luft- und Raumfahrt

-

Dünnschichttechnik

-

Biomedizin

-

Optik und Glasverarbeitung

-

Schmierstoffindustrie (Grundöle, Additive, Formulierer)

Brauchen Sie mehr Vielseitigkeit?

Entdecken Sie das modulare Multifunktionstribometer MFT-5000.

Benötigen Sie eine kompakte Tribologie?

Erfahren Sie mehr über unser Tisch-Multifunktionstribometer MFT-2000.

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved