Summary

- Several electrified tribology and mechanical test modes

- e-Traction, e-4 Ball, e-Reciprocating, e-Rotary, e-Fretting

- e-Twin Roller and e-3 Roller (Rolling Sliding Pitting)

- DC mode, AC mode, with Impedance, spark studies

- Closed-loop temperature control

- Highly versatile load and speed range

What is electric vehicle tribology? Electric vehicle tribology is a specialized branch of tribology that focuses on studying the friction, wear, and lubrication of components specific to electric and hybrid vehicles (EVs). Studying electrified tribology is essential for optimizing the performance and longevity of electrified systems such as electric and hybrid vehicles. Standard information that can be gathered from EV tribology testing are:

- Change in lubricant film properties due to the effect of charge carried by the fluid

- Effect of EDM or arcing on friction.

- Study stray current (pitting, loose particles, brittle materials)

- Effect of higher temperature at the interface

- Tribology associated with higher operational speed

- Development of specialized materials and lubricants that are tailored to withstand the unique mechanical and electrical stresses

Rtec-Instruments’ electrified tribology solutions:

Our range of tribology testing equipment for electric vehicles includes modules and platforms configured for the full spectrum of electrified testing — from linear reciprocating and block-on-ring to rotary, fretting and twin-roller setups. Features include:

- Multiple electrified tribology modes

- DC and AC modes with impedance measurement, spark and arcing studies.

- Closed-loop temperature control paired with high speed and versatile load ranges.

- Purpose-built for EV tribology: bearings, e-axles, seals, connectors, coatings, thermal fluids and specialized lubricants.

Need help or have a question?

Learn More About Our Tribometer Platforms

Electrified Tribometer Platforms

Learn more about our versatile tribometer platforms that provide friction, wear, and surface properties of various materials under a multitude of environments and electrified testing conditions.

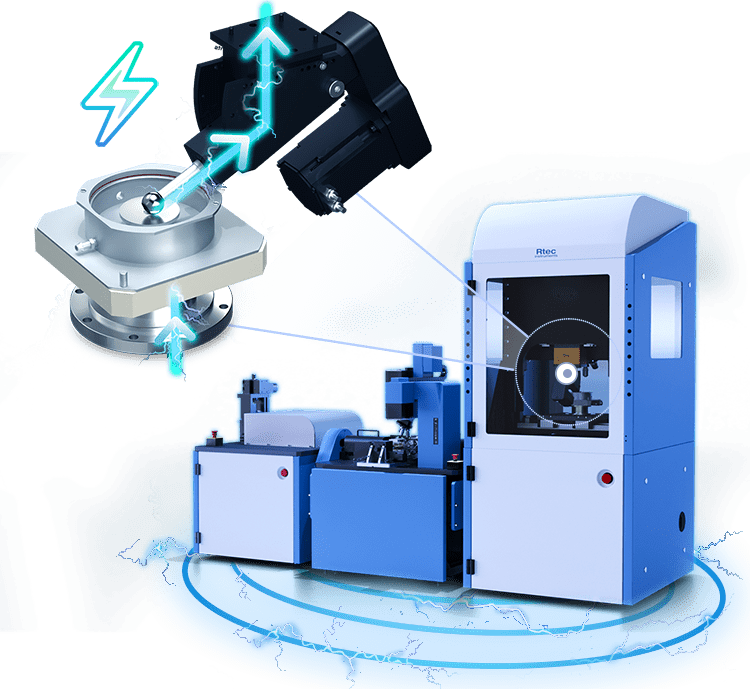

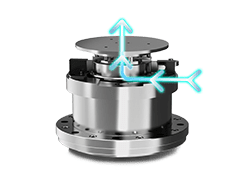

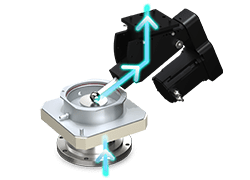

Electrified MFT-5000 Platform

Rtec-Instruments’ MFT-5000 offers a versatile platform for conducting multiple EV tribology tests, encompassing a range of common electrified applications, some of which are highlighted below.

Linear Reciprocating

Up to 80 Hz speed

Block On Ring, Bearings

Up to 6000 RPM

Rotary

Speeds up to 9000 RPM

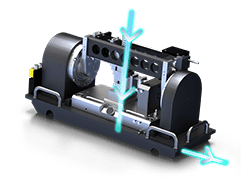

Traction Module

Up to 200 N, 6 to -6 m/s

4-Ball, Thrust Washer

Up to 10,000N tests

Fretting, HFRR, SRV

From 10 µm to 4.0 mm stroke

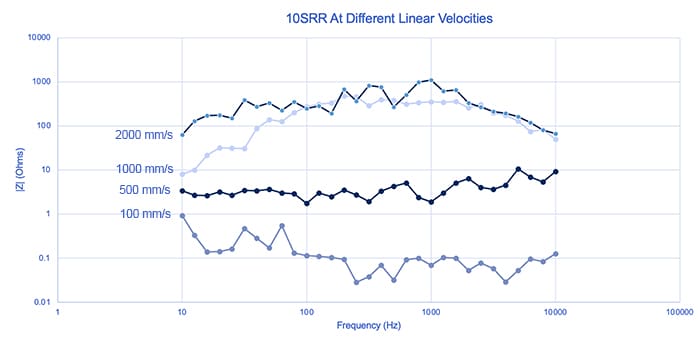

Measure Impedance vs. Changing Linear Velocities

Transition from Ohmic to Capacitive Behavior over lubrication regimes. By precisely measuring impedance against varying linear velocities, we provide valuable insights into the dynamic tribological behavior of materials under different speed conditions.

The EV Tribology Solution

With advanced capabilities and customizable setups, Rtec-Instruments’ tribology equipment for electric vehicles supply the advanced EV tribology that empowers researchers and engineers to optimize materials, lubricants, and more for enhanced durability and efficiency in electric vehicle applications.

-

Bearings

-

Seals

-

Thermal Fluids

-

Lubricants

-

Connectors

-

Coatings

-

Materials

-

Brakes

-

Shafts

-

Gears

Learn more about our electrified tribology platforms.

The Universal MFT-5000 Tribometer

Take a closer look at the Multi Function Tribometer and its extensive range of testing setups.

Micropitting Rig

Learn more about the MPT-3000 Micropitting Tester’s cutting-edge features and applications.

Twin Roller Tribometer

Explore how the Twin Roller Tribometer revolutionizes friction and wear testing with its unique dual-roller configuration.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved