Fine Ceramics

Rtec Instruments provides several standard and customized ceramic industry solutions to evaluate ceramics in coatings, materials, and components that are used across a wide range of applications. Our innovate ceramics tests support research and quality control in aerospace, the medical field, and ceramic tool assessment.

Ceramic Industry Solutions We Offer

We provide the ceramics industry with the analysis needed for quality control and assessment to improve ceramic products and mechanical systems.

Friction, Wear

Several applications use ceramics because of their superior hardness, high wear resistance, good chemical resistance, and stability at high temperatures. Extreme applications, such as high loads, high temperatures, and corrosive environments commonly use ceramics.

Perform friction, wear, and tribology tests for ceramic coatings or materials under a wide test load range (from mN to 12,000 N) across a wide controlled environmental condition (-120°C to 1200°C), and under vacuum, corrosive, or high pressure environments. The choice depends on the application.

Scratch Resistance, Adhesion, Hardness

Several applications require testing ceramic coating surfaces. Based on the coating process, the end results can be very different. Rtec Instrument provides solutions for characterization of coating adhesion, scratch hardness, scratch resistance, wear, durability, fretting, roughness, corrosion resistance, and abrasion resistance. These ceramics tests are available at nano, micro and macro scales across a wide temperature and environmental conditions.

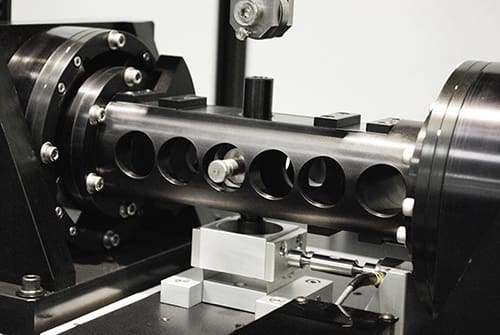

Fretting Wear

Friction reduction and wear protection are core properties of engineering ceramics and are of crucial importance to the ceramics industry. Rtec-Instruments provides unequaled specifications for stroke and frequency control for fretting evaluation. Controlled stroke from 5 microns and frequency up to 500 Hz frequency across a wide temperature range makes it an ideal fretting wear tester.

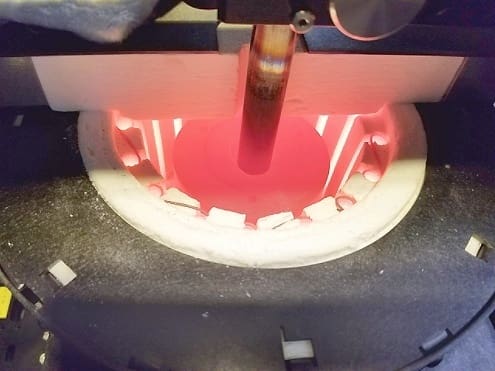

High Temperature

Perform up to 1200°C high temperature tests of ceramic materials, coatings, and components. Characterize hot hardness, friction, fretting, wear, and many more under controlled atmospheric conditions.

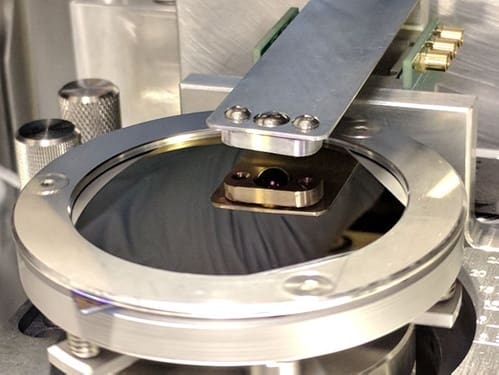

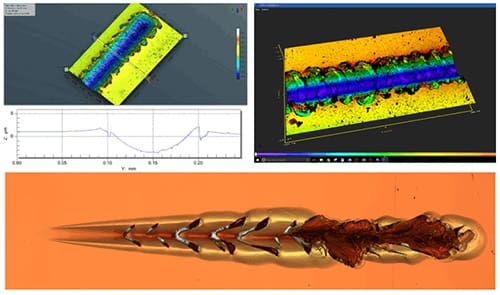

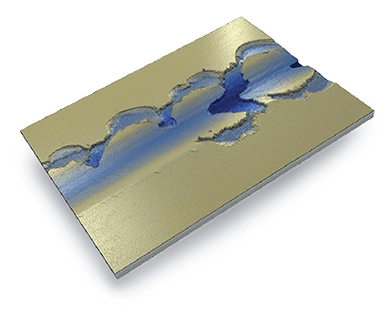

Ceramics 3D Imaging

Combine 4 imaging modes in one head. It requires only one mouse click to alternate between the different imaging modes. Image any surface with ease – transparent, flat, dark, flat, curved, and more.

See Our Ceramics Industry Solutions In Action

Watch as we demonstrate how our instruments can fulfill all of your ceramics research and quality control needs.

Need Versatility?

Need Fretting?

Check out our FFT Fretting Testers Series.

Need Indentation and Scratch Testing?

Need 3D Microscopy?

Check out our 3D Optical Profilometers, the UP Series

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved