Detailed Module Information

Module Features

- Room to max 1200°C temperature range

- Construction from high temperature alloys

- Several interchangeable modules on the same platform.

- Negligible thermal drifts

- Safe operation with closed wall chambers.

Why study high temperature tribology? Characterizing tribological, friction and wear properties of material at high temperatures is critical in applications, such as engines, turbines, aerospace, power plant constituent parts, hot rolling, ceramics, combustion engine, and metallic alloys where materials are subjected to high temperatures.

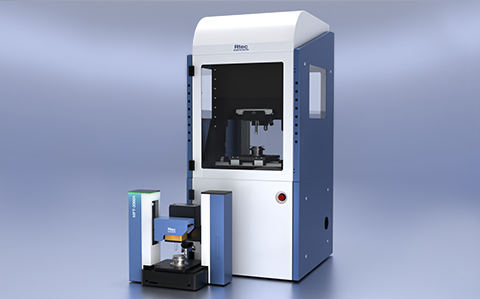

Rtec high temperature tribometer modules to study material and coating friction, wear, hardness up to 1200°C. The test can run under a wide range of motion, load, and speed.

Need help or have a question?

Learn More About The Platforms

The MFT Series Tribometers

Explore our MFT Series Tribometers for versatile surface and material testing.

One Platform. So Many Ways

Rtec Instruments’ high temperature tribometer provides interchange modules on the same platform. Wide load range mN to 5000N to simulate several high temperature tribology applications. Choice of module and test conditions depend on the final high temperature mechanical and surface testing application.

Linear

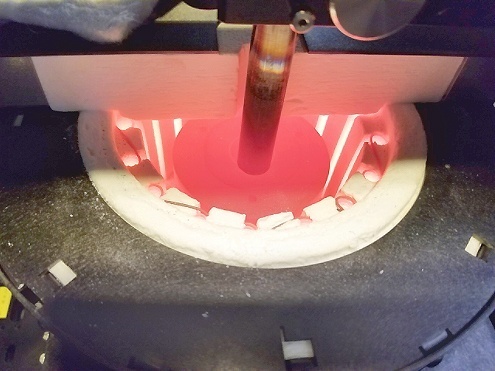

Fast reciprocating high speed module with speeds up to 80 Hz. room to 500/1000/1200°C range

Rotary

High temperature rotary tribometer module with speeds 0.001 – 10,000 RPM, room to 500 /1000/ 1200°C range.

Upper Rotation

Twist compression, thrust washer, and ring on disk with in-line torque up to 180/500°C range

Block On Ring

High temperature block on ring tribometer module with speeds up to 6000 RPM, room to 500°C range

Vacuum

Fretting

Fretting tribometer module with 10 µm to 2.8 mm stroke, up to 300Hz speed, up to room to 180°C / 400°C / 800°C range

Data and Analysis

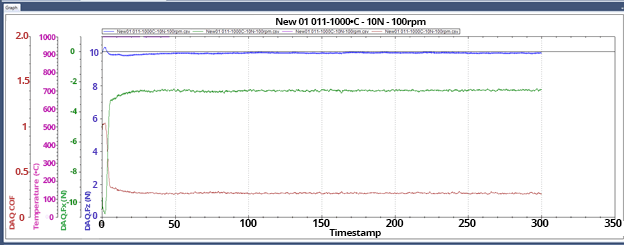

The graph shows friction coefficient at elevated thermal conditions for certain metallic alloy to simulate service conditions.

Solution To

Due to its multiple configurations, high temperature mechanical and surface testing is achieved across a wide range of industries:

-

Aerospace

-

Automotive

-

Ceramics

-

Hard Coatings

-

Lubricants

-

Metal

-

Power Plants

-

Coatings

Need More Versatility?

Need Compact Tribology?

Learn about our benchtop Multi Function Tribometer, the MFT-2000.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved