Block on Ring Test Module Information

Module Features:

- Rigid design to support mN to 5000 N loads

- Dry and lubricated tests

- -50°C to 500°C temperature

- Up to 50 Nm torque motors

- In-line Torque measurement

Block on ring tester helps determine the coefficient of friction, wear, friction, rate of wear, volume wear, and EP. Including wear resistance of lubricants, greases, bearings, rings, and shafts. The test can run under a wide range of load, sliding speed, rotational speed and temperature. The test setup typically involves a block loaded against a rotating shaft or ring.

Rtec Instruments’ block on ring tribology module allows several ASTM and customized tests on the same platform. We support the rotating shaft on both ends to prevent bending under high loads. The versatility of the block on ring module allows real components including shafts, power transmission components, tapered roller bearings, thrust bearings, and their counterparts mount with little modifications. Computer controlled applied load, speed of rotation, test temperature, and lubricant flow rate creates highly repeatable results.

Need help or have a question?

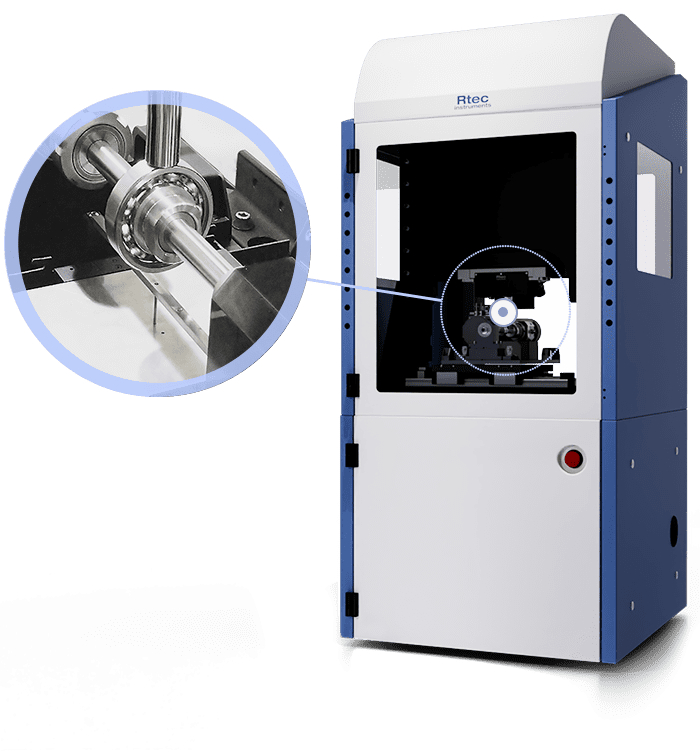

Learn More About The MFT-5000 Platform

The MFT-5000 Tribometer

Learn more about the versatile MFT-5000 tribometer that provides friction, wear, and surface properties of various materials and coatings under a multitude of fluids, environments, and testing conditions.

Watch The Block on Ring Module in Action

One Module and so Many Ways.

Customize The Block On Ring Module For Your Needs

Timken OK Load Test Setup

Standard Block On Ring

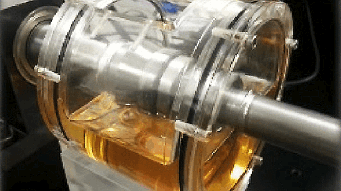

Block on Ring with Oil

Electrical Ring Slip Test

Bearings Test

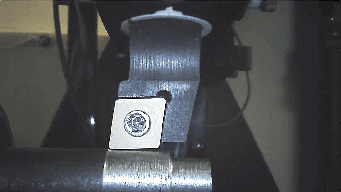

Cutting Tools Test

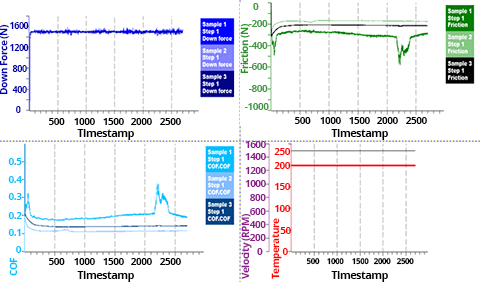

Test Data and Analysis

Wear Tests

The test analyses friction and wear characteristics of greases or oil in sliding applications on block on ring test machine. Pumps circulate and control lubricant and grease flow rates. These tests are configured by defining the temperature, loading rate, test load, rotation speeds.

Extreme Pressure EP Tests

This procedure covers the determination of the extreme pressure properties of lubricating oil or greases in sliding applications. The test involves increasing load step or linear mode until a seizure or sudden increase of cof change occurs. The Timken method tests grease and lubricants (ASTM D2509, ASTM D2782, G77, D2714, D2981, D2704, JASO M358 ).

Custom Tests

Rtec Instruments’ block on ring tribometer performs many customized tests, such as oscillating tests where the rings oscillate clockwise and counter clockwise to a pre-determined angle or number of rotations. These tests are frequently performed to evaluate the performance of solid lubricants, coatings or surface texture on bearings, and applications where there is frequent change in direction or limited motion between the two counterparts.

Figure shows the comparison of different lubricants.

Standard test block HRC30 against a Timken ring, under constant load (1500N) and velocity (1500 rpm) at 200°C were used.

The Block on Ring Tribometer Solution

Block on ring test machine is highly versatile and therefore used across many industries.

-

Aerospace

-

Automotive

-

Hard Coating

-

Lubricants

-

Metal

-

Polymer

The MFT-5000 Has More To Offer

Take a closer look at the Multi Function Tribometer, the MFT-5000.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved