Tribocorrosion Module Information

Main Features:

- Integrated 3 Electrode Potentiostat

- Up to 70°C temperature (optional 150°C)

- Upper or lower conductive samples

Why Tribocorrosion? Wear and corrosion involves several mechanical and chemical processes. The combination of these processes results in significant interaction that as failure mechanisms may occur beyond the individual contributions of mechanical wear and corrosion. Tribocorrosion studies help quantification of this wear corrosion synergism, or interaction, to minimize overall material loss and understand systems better.

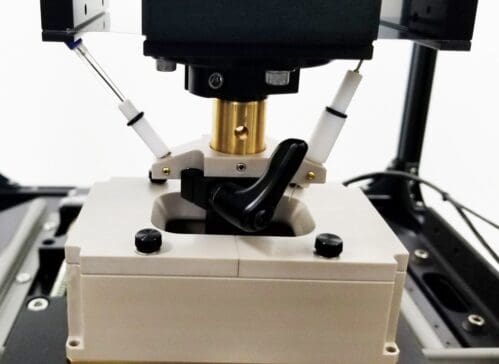

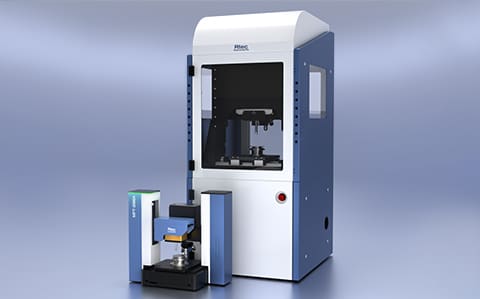

Rtec Tribocorrosion tester cell mounts on the MFT series (Tribometer) or the SMT-5000 (Indentation and Scratch Tester). It equips a robust 3 electrode measurement system. During the test, the cell simultaneously measures real-time current, voltage, friction, wear, temperature, down force, and acoustic emissions.

Need help or have a question?

Learn More About The Platforms

The MFT Series Tribometers

Explore our MFT Series Tribometers for versatile surface and material testing.

Features

Rtec Tribocorrosion tribometer contains various features to improve testing capabilities.

Electrochemical Cell + Tribometer Combination

The floating ground integrated potentiostat comes with a wide current, voltage, and oscillating frequency range.

Tribocorrosion Test Modes

Study tribocorrosion in several test modes on the same platform.

- Tribology

- Scratch Adhesion

- Hardness

- Fretting

Test Samples

The unique design allows either upper or lower samples (working electrode).

Tribocorrosion Analysis

Setup

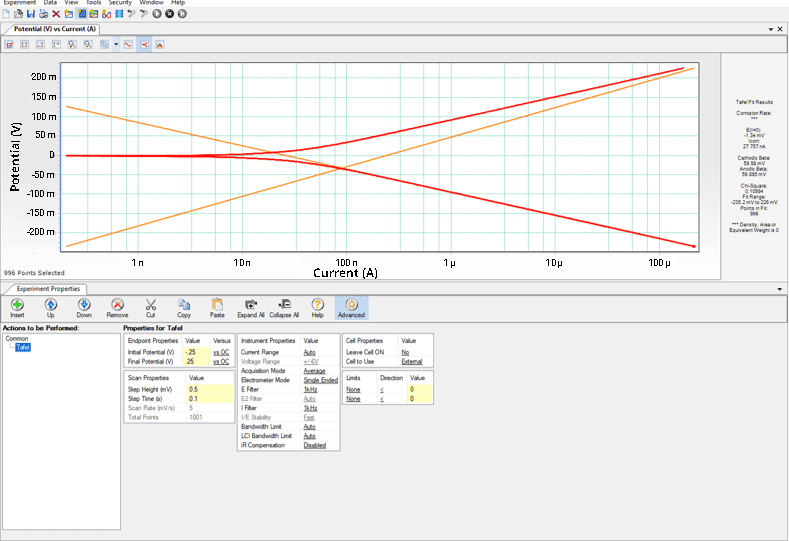

To investigate synergy of wear and corrosion of steel, the tests were carried out under cathodic and no cathodic protection conditions. We conducted 3 different load conditions (10, 100, 200 N at 2 Hz sliding frequency) at 70°C. The electrochemical polarization tribocorrosion tests were performed with a standard Ag/AgCl reference electrode and a platinum counter electrode.

OCP – Open Circuit Potential (Ecorr)

The plot below shows the open circuit corrosion potential, Ecorr obtained from the integrated potentiostat.

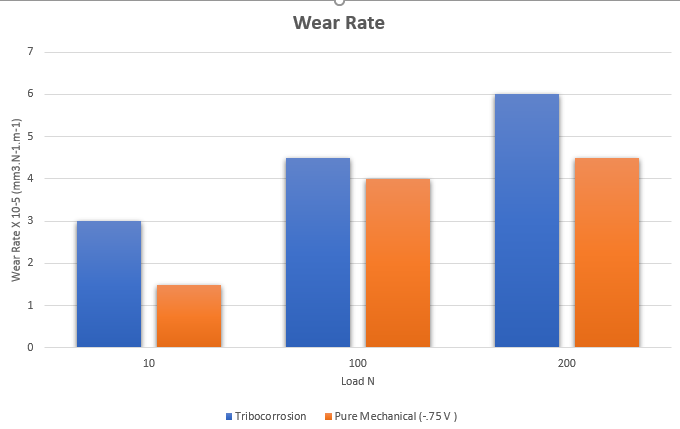

Results

The figure below shows the wear rate difference between the cathodic and non cathodic polarization conditions. The difference of the wear rate shows the synergy of the chemistry used during the test.

Conclusion

This corrosion tribology testing showed the importance of tribocorrosion studies. The wear loss rate attributed between mechanical vs mechanical + corrosion test was significantly different.

Tribocorrosion Solution To

The Tribocorrosion test setup is used extensively across a wide range of industries:

-

Bio-materials

-

Coatings

-

Lubricants

-

Metals

-

Metal Working Industry

Need More Versatility?

Need Compact Tribology?

Learn about our benchtop Multi Function Tribometer, the MFT-2000.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved