Fretting Wear Tester Overview

Main Features:

- 5 µm to 4 mm controlled stroke for micro-to-macro fretting studies

- Up to 300 Hz test frequency for accelerated wear evaluation

- High-frequency piezo friction sensors for precise real-time data

- Flexure-based design ensuring ultra-stable, backlash-free motion

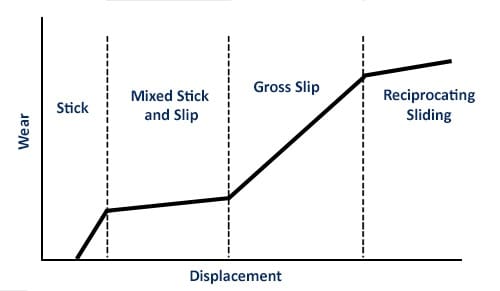

What is fretting? Fretting occurs when small oscillatory motion between two contacting surfaces generates localized wear, debris buildup, and rapid material degradation. This micro-motion wear mechanism appears in demanding environments—including aerospace, automotive, energy, and precision machinery—where component reliability is critical. Accurate fretting wear testing helps researchers and engineers understand material behavior, fatigue risks, and long-term performance under realistic conditions.

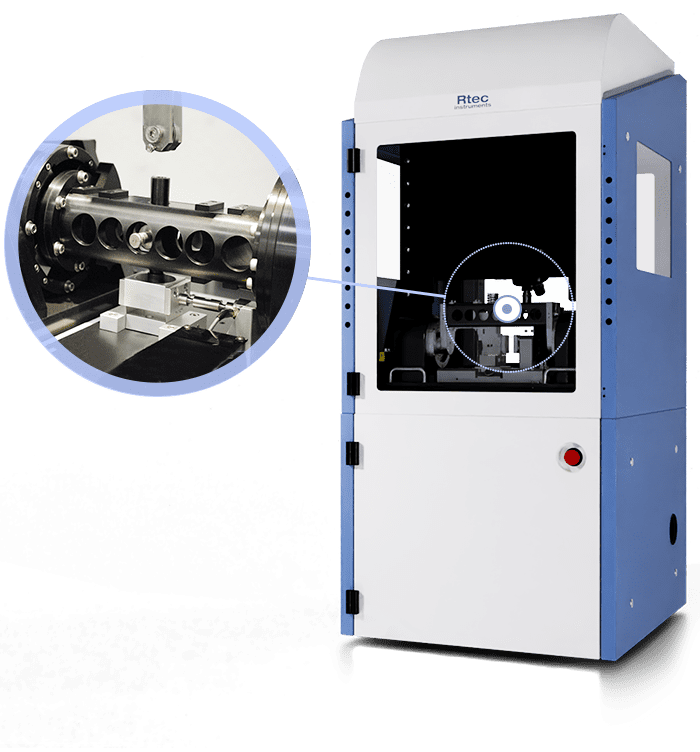

Rtec-Instruments’ Fretting Solution The MFT-5000 integrates a state-of-the-art fretting module that brings exceptional performance to a multifunction tribometer platform. Its voice-coil actuator, piezo sensors, and wide stroke and frequency range deliver unmatched control and measurement sensitivity in the industry. With stable motion from 5 µm stroke at 300 Hz, the system enables reliable fretting wear evaluation and fretting test analysis across metals, coatings, polymers, and advanced materials. This modular approach allows laboratories to perform high-quality fretting testing on a tribometer while maintaining the flexibility to run other tribological methods—making the MFT-5000 a versatile, future-ready solution for both industry and university research.

Need help or have a question?

Learn More About The MFT-5000 Platform

The MFT-5000 Tribometer

Learn more about the versatile MFT-5000 tribometer that provides friction, wear, and surface properties of various materials and coatings under a multitude of fluids, environments, and testing conditions.

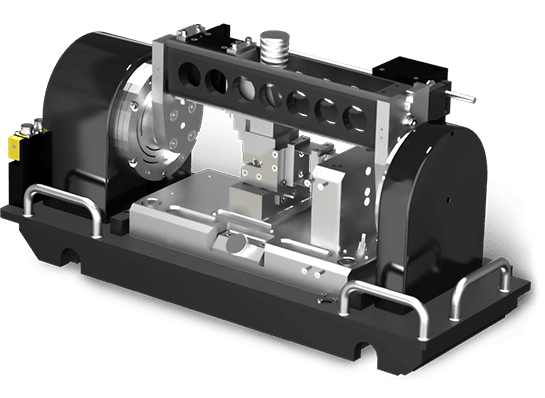

Voice-Coil Actuation with Real-Time Stroke Control

Breakthrough advancements in voice-coil actuation and high-frequency signal processing enable the MFT-5000 to deliver exceptionally stable fretting tests with controlled strokes below 5 microns. This precision allows researchers to characterize fretting wear across the full range—from micro-scale motion to macro-amplitude conditions. Combined with ultra-sensitive piezo load cells, a rigid mechanical frame, and low-noise electronics, the system provides quantitative fretting test analysis

The Smallest Controllable Stroke: 5µm to 4mm, Up to 300Hz

Real-time LVDT feedback delivers precise stroke, frequency monitoring, and correction. Optional high-force coils expand the load capacity for demanding applications.

High Reliability Flexure Design

The flexural suspension guides the magnet assembly without bearings. The magnetic flexure-based design provides the control required for the most sensitive of tests.

Environmental and Electrical Measurement Options

Humidity, temperature, inert gas, and electrified testing allow for realistic fretting wear simulation.

High-Frequency Piezo Force Sensors

Ultra-sensitive piezo friction sensors with low-noise amplification capture rapid force changes during high-frequency reciprocating motion, providing accurate real-time insights into fretting wear and material behavior.

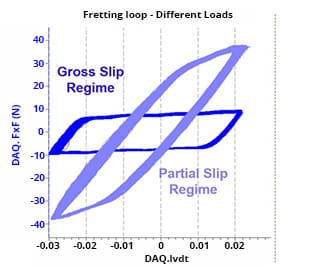

Fretting Test Data and Analysis

Fretting Loops

Rigid design with accurate real-time friction force allows the measure of fretting loops at different temperatures, and loads.

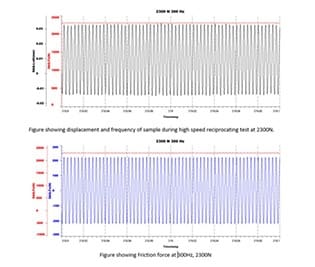

Real Time Friction Curves at 300 Hz

The graph shows real-time friction data at 300 Hz, 2300 N test on dry material fretting test.

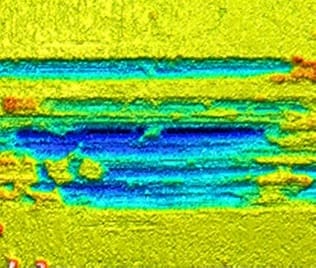

Fretting Failure Marks

Rtec-Instruments’ 3D optical profilometer allows to create 3D images of surfaces with ease.

High-Speed Controllers

Common Debris and Damage Mechanisms

- Debris formation from asperity contacts

- Oxidation-driven wear influenced by humidity, temperature, or chemical changes

- Lubrication starvation and oil breakdown leading to accelerated wear

- Electrical discharge–induced material removal

- Repetitive micro-collisions between surfaces

- Fatigue-related cracking and early-stage debris generation

- Polymerization of organic materials at the contact

- Highly oxidized fine particulate debris

- Residual steady stage flow of debris

- Diffusive wear processes

- Melting-induced wear at elevated conditions

Specification Summary

Reliable and Customizable

The MFT-5000’s fretting module delivers industry-leading performance through precise motion control, high-frequency capability, and advanced sensing technologies. The following specifications highlight the system’s range, accuracy, and flexibility for comprehensive fretting wear testing across diverse materials and conditions.

Actuators

- Displacement 5 µm-4mm

- Resolution: 0.1 µm

- Oscillation frequency: Up to 300 Hz

Environmental

- Temperature control

- Humidity controlled chamber

Sensors

- Potentiostat

- Acoustic Emission

- Electrical Contact Resistance

Common Standards

- ASTM E2789

- ISO 19291

- ASTM D6425

- ASTM D7421

- ASTM D5707

- ASTM D5706

- ASTM D7594

- DIN 51834-2

- DIN 51834-3

- DIN 51834-4

The Fretting Testing Applications

The MFT-5000 delivers a highly versatile fretting test solution trusted across research labs and industrial environments. Its ability to simulate real-world micro-motion conditions makes it ideal for evaluating materials, coatings, components, and interfaces in demanding applications where reliability and durability matter.

-

Aerospace

-

Automotive

-

Semiconductor & Electronics

-

Bio Materials & Medical Devices

-

Pharmaceuticals

-

Metal, Ceramics, Polymers

-

Optics and Glasses

-

Lubricants & Additive Formulations

Need Focused Fretting Testing?

Take a look at Rtec-Instruments’ FFT Fretting Testers.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved