Brake Testing Module Information

Features

- Conforms to SAE J2522

- Data comparative to dynamometers

- High torque motors up to 50 Nm

- In-line Torque, acoustic, and temperature measurement

- Reaches 500°C brake test conditions

Why Brake Friction? Brake shoe friction materials are security components of every vehicle. Moreover, the advent of hybrid and electric cars, regenerative braking, and current regulations on particulate emissions are vital motivations for developing new brake friction materials, mainly more wear resistant. This applies also to the brake rotors.

Rtec Instruments Solution – The brake material tribometer is perfect for lab scale evaluation of a friction material and cost efficiency. High torque 3 phase motors to deliver 50 Nm torque at high speeds allow it to conform to SAE J2522. It enables tests at varying pressures, speeds, temperatures, and deceleration conditions. Rtec Instruments’ MFT 5000 offers unique advantages over typical small bench top testing systems and full-blown dynamometers.

Need help or have a question?

Learn More About The MFT-5000 Platform

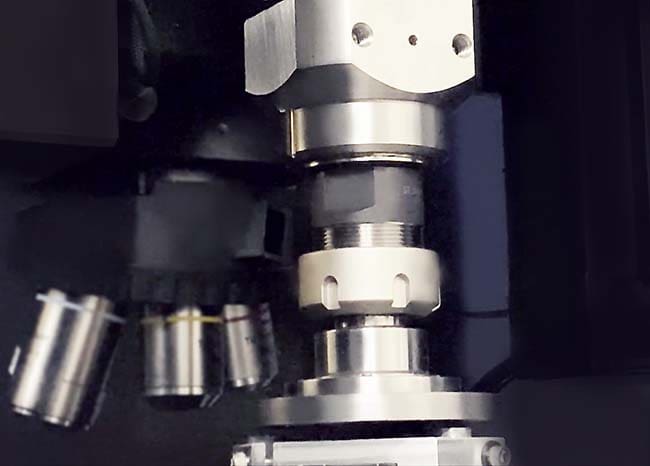

The MFT-5000 Tribometer

Learn more about the versatile MFT-5000 tribometer that provides friction, wear, and surface properties of various materials and coatings under a multitude of fluids, environments, and testing conditions.

Watch Brake Testing in Action

Simulating Brake Testing

The Rtec Brake material screening tester mounts on the MFT-5000 tribometer. With a rigid construction, the MFT-5000 tribometer has high torque motors up to 50 Nm. Firstly, this allows testing operating conditions as mentioned in SAE J2522. Secondly, the data generated is equivalent to large dynamometers. In addition, the tester comes with several sensors that allow for more comprehensive data generation in a short time. The brake material screener thus evaluates the effectiveness of the tribological behavior and the tribological properties of the test candidates. Promising couples move on to the component level. The useful is separated from the meaningless.

Test Setup and Results

The MFT 5000 platform can work across various loads (up to 10,000 N) and speeds. SAE J2522 protocols, such as Green µ characteristics, Speed/Pressure sensitivity, cold application, fade, and recovery, are easily simulated. Here, we demonstrate using Rtec’s MFT 5000 brake material testing solution to simulate a subsection of SAE J2522.

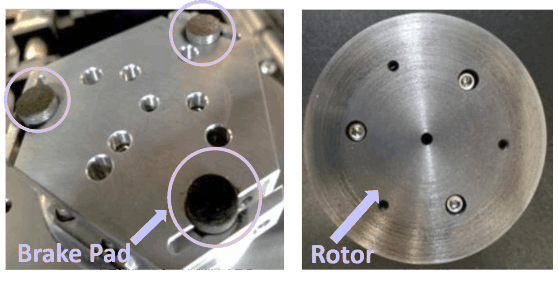

Setup

First, we cut sample coupons 12.7 mm X 6.35 mm from real brake and mounted them on a self-leveling brake holder for uniform contact. The counter surface was a 320 Grit cast iron disc. To simulate a snub from SAE J2522, the test started at 300N (0.75 MPa contact pressure) at 2089 rpm. After that, the tester reduced speeds to 787 rpm under load in 5.5s. In other words, these conditions represented a change in speed for motor vehicles from 80 to 30 Km/hr. The load represented 3000 kPa in a fluid line. The tester controlled the speed and load while measuring the interacting surfaces’ torque, friction, and temperature.

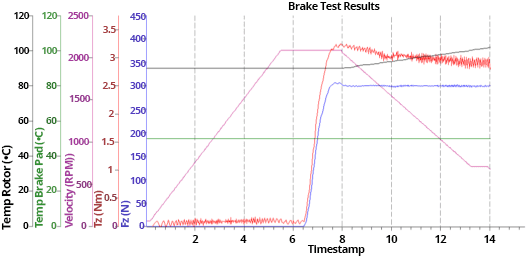

Results

The tester records several advanced sensors, such as acoustic emission and surface temperature, with high precision. The Figure shows the data collected during one cycle. Next, the debris produced is collected for further analysis.

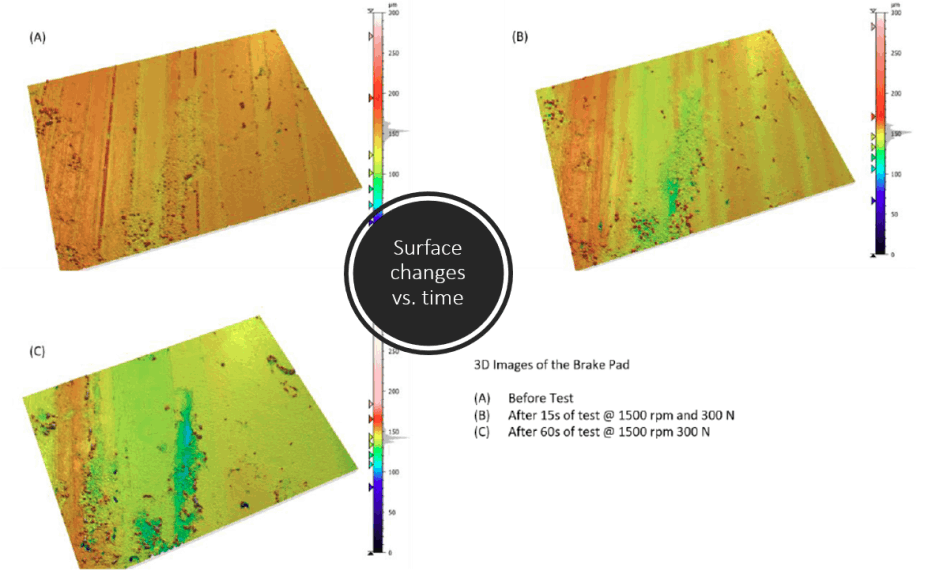

3D Profilometer For Surface Analysis

The Lambda Profilometer looks at brake or rotor surfaces at nm resolution. Furthermore, it is optimized for brake surfaces (dark, rough surfaces). The spinning disk confocal microscopy allows analysis of volumetric wear, surface roughness, and more of brakes or rotor surfaces. In addition, the profilometer’s dark field imaging mode allows for easy quantification of debris generation and scratches.

Solution To

Several Industries use Rtec Instruments brake screening material tester as it corresponds to dynamo meter test results, but at much cost efficiency and effectiveness.

-

Aerospace

-

Automotive

-

Mechanical Engineering

-

Robotics and Automation

The MFT-5000 Has More To Offer

Take a closer look at the Multi Function Tribometer.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved