Module Information

Merkmale

- Entspricht der SAE J2522

- Ergebnisse vergleichbar mit Dynamometern

- Motoren mit hohem Drehmoment bis zu 50 Nm

- Inline-Messung von Drehmoment, Geräuschentwicklung und Temperatur

- Erreicht Bremsprüfbedingungen von 500 °C

Warum an Bremsen entwickelt? Bremsbeläge sind wichtige Sicherheitselemente jedes Fahrzeugs. Darüber hinaus sind die Einführung von Hybrid- und Elektroautos, regeneratives Bremsen und aktuelle Emissionsvorschriften zu Feinstaubemissionen wichtige Motivationen für die Entwicklung von neuen Bremsbelägen, zumeist von Verschleißbeständigeren. Selbiges gilt für die Bremsscheibe.

Die Prüflösung von Rtec-Instruments – Das Tribometer Bremswerkstoffe eignet sich perfekt für die Bewertung von Reibmaterialien im Labormaßstab und ist kosteneffizient. Dreiphasenmotoren mit hohem Drehmoment, die bei hohen Drehzahlen ein Drehmoment von 50 Nm liefern, ermöglichen die Einhaltung der Norm SAE J2522. Es ermöglicht Tests unter verschiedenen Pressungs-, Drehzahl-, Temperatur- und Verzögerungsbedingungen. Das MFT 5000 von Rtec Instruments bietet einzigartige Vorteile gegenüber typischen kleinen Tischprüfsystemen und vollwertigen Dynamometern.

Brauchen Sie Hilfe oder haben Sie eine Frage?

Erfahren Sie mehr über die MFT-5000-Plattform

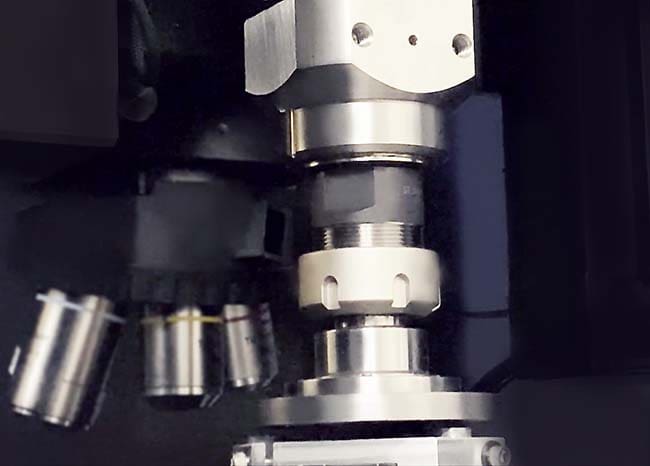

Das MFT-5000 Tribometer

Erfahren Sie mehr über das vielseitige MFT-5000-Tribometer, das Reibung, Verschleiß und Oberflächeneigenschaften verschiedenster Materialien unter einer Vielzahl von Umgebungen und Prüfbedingungen erfasst.

Sehen Sie den Bremsenscreener im Betrieb

Das Bremsverhalten simulieren

Der Rtec-Bremsmaterial-Screener wird auf dem Tribometer MFT-5000 montiert. Das Tribometer MFT-5000 verfügt über eine starre Konstruktion und Motoren mit einem hohen Drehmoment von bis zu 50 Nm. Erstens ermöglicht dies die Prüfung von Beanspruchungsbedingungen gemäß SAE J2522. Zweitens entsprechen die generierten Daten denen großer Dynamometer. Darüber hinaus verfügt das Prüfgerät über mehrere Sensoren, die eine umfassendere Datengenerierung in kurzer Zeit ermöglichen. Somit bewertet der Bremsmaterial-Sreener die Wirksamkeit des tribologischen Verhaltens und die tribologischen Eigenschaften der Prüfkandidaten. Aussichtsreiche Paarungen wechseln zur Komponentenebene. Es wird das sinnvolle vom sinnlosen getrennt.

Prüfaufbau und Ergebnisse

Die MFT 5000-Plattform kann mit verschiedenen Normalkräfte (bis zu 10.000 N) und Geschwindigkeiten arbeiten. SAE J2522-Protokolle, wie z. B. Green-µ-Eigenschaften, Geschwindigkeits-/Pressungsempfindlichkeit, Kaltstart, Fading und seine Rückbildung, lassen sich leicht simulieren. Hier zeigen wir anhand der MFT 5000-Bremsmaterialprüfungslösung von Rtec, wie ein Teilbereich von SAE J2522 simuliert werden kann.

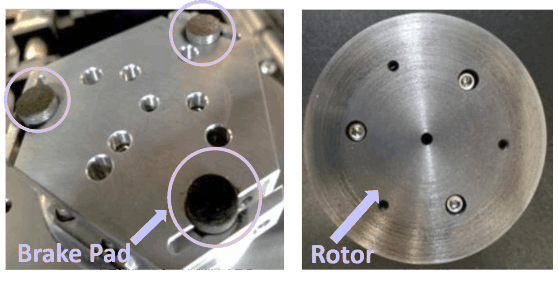

Prüfaufbau

Zunächst schneidet man Probenstücke mit den Maßen 12,7 mm x 6,35 mm aus einem echten Bremsbelag aus und befestigten sie auf einem selbstnivellierenden Bremsenhalter, um einen gleichmäßigen Kontakt zu gewährleisten. Die Gegenfläche war eine Gussscheibe mit einer Körnung von 320 der Reibfläche. Um eine Bremsung gemäß SAE J2522 zu simulieren, begann der Test bei 300 N (0,75 MPa Kontaktdruck) und bei 2089 U/min. Danach reduzierte der Screener die Drehzahl unter Last in 5,5 Sekunden auf 787 U/min. Mit anderen Worten: Diese Bedingungen entsprachen einer Geschwindigkeitsänderung bei Kraftfahrzeugen von 80 auf 30 km/h. Die Belastung entsprach einer Druck von 3000 kPa in einer Flüssigkeitsleitung. Der Screener kontrollierte die Drehzahl und die Last, während er das Drehmoment, die Reibung und die Temperatur der miteinander in wechselwirkenden Oberflächen maß.

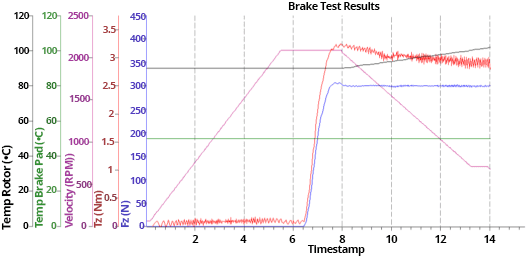

Ergebnisse

Der Screener zeichnet das Versuchsgeschehen mit mehreren fortschrittliche Sensoren, wie akustische Emissionen und Oberflächentemperatur, mit hoher Präzision auf. Die Abbildung zeigt die während eines Zyklus gesammelten Daten. Anschließend werden die entstandenen Verschleißpartikel für weiterführende Analysen gesammelt.

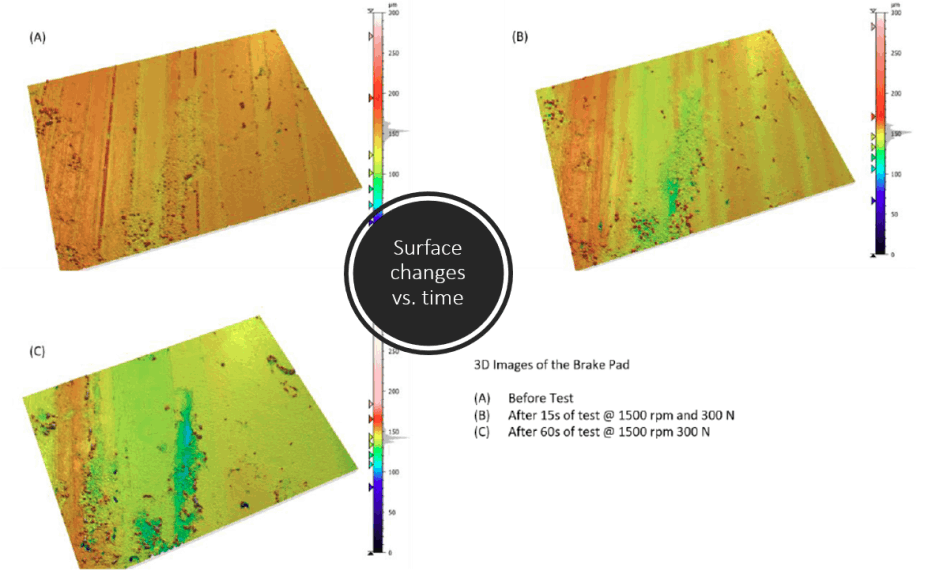

3D-Profilometer für Oberflächenanalysen

Das Lambda-Profilometer untersucht Veränderungen der Brems- oder Rotoroberflächen mit einer Auflösung im Nanometerbereich. Darüber hinaus ist es für Bremsflächen (dunkle, raue Oberflächen) optimiert. Die Spinning-Disk-Konfokalmikroskopie ermöglicht die Analyse vom volumetrischen Verschleißbetrag, Oberflächenrauheit und weiteren Eigenschaften von Brems- oder Rotoroberflächen. Darüber hinaus ermöglicht der Dunkelfeld-Bildgebungsmodus des Profilometers eine einfache Quantifizierung von Abrieb und Kratzern.

Branchenlösungen

-

Luft- und Raumfahrt

-

Automobilindustrie, Mobilität

-

Maschinenbau

-

Robotik und Automatisierung

The MFT-5000 Has More To Offer

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved