Vacuum Tribometer Overview

- Ultra-high vacuum capability down to 10⁻⁷ torr

- mN to 200 N friction and down force

- Cryogenic cooling from 3.5 Kelvin

- Interchangeable tribology, hardness and scratch modules

- Temperature range up to 400 °C (optional up to 1000 °C)

Why Vacuum Tribology? Advancements in space, semiconductor, aerospace, and thin-film technologies have driven increased interest in understanding material and coating behavior under vacuum conditions. However, friction, wear, and adhesion mechanisms in vacuum differ significantly from those observed in ambient environments. Because of this, developing next-generation vacuum-compatible components requires tribology testing under conditions that closely replicate real operating environments.

For this reason, meaningful evaluation of materials for vacuum applications depends on vacuum tribology testing performed under realistic thermal, mechanical, and environmental conditions.

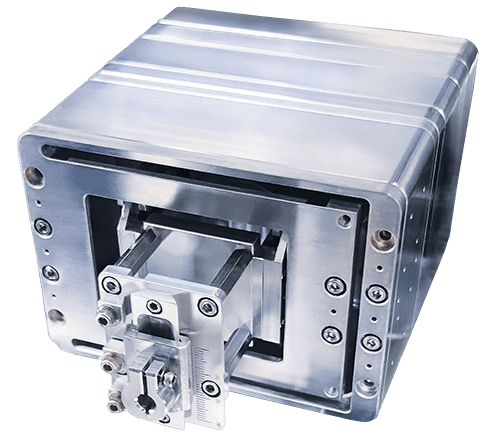

The Rtec MVT-2 Vacuum Tribometer provides precise control of force, speed, and temperature for comprehensive analysis of material properties in vacuum. In addition, a unique system design incorporating patented force sensors delivers exceptional measurement accuracy and repeatability.

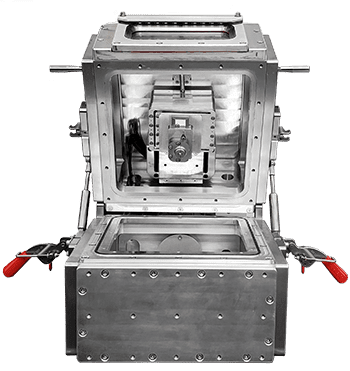

An open-face chamber architecture improves usability by providing full visibility during sample changes. At the same time, multiple friction, lubrication, and wear test configurations—including pin-on-disc, ball-on-disc, and linear reciprocating tests—can be performed on the same platform.

Moreover, a modular system layout enables indentation, scratch, and tribology testing without changing instruments. Multiple standard vacuum chamber configurations are available to accommodate a wide range of applications.

Need help or have a question?

Vacuum Tribometer Features

Rtec-Instruments’ vacuum tribometer integrates several patented and system-level design innovations. As a result, it is the only commercially available vacuum tribometer capable of performing a broad range of vacuum tribology tests on a single platform.

Patented Force Sensor

Rapid Vacuum Generation

Achieve 10⁻⁷ torr vacuum in approximately 45 minutes using integrated roughing and turbo-molecular pumping systems.

Rotary and Linear Modes

Rotary testing up to 5000 RPM and linear reciprocating motion up to 6 mm/s, with optional piezo-driven stages for high-precision motion control.

Cryogenic to High Temperature Control

Closed-loop liquid helium cryogenic cooling enables testing down to 3.5 K, while standard heating supports up to 400 °C, with an optional 1000 °C high-power heating chamber.

Closed-Loop Force Control

Real-time closed-loop force control during testing allows automated generation of friction vs. load and friction vs. speed curves under vacuum conditions.

Several Application Modules

Modular configuration enables scratch testing, indentation, and tribology experiments on the same vacuum tribometer platform without system reconfiguration.

Environmental Control

Temperature can be dynamically adjusted during experiments, allowing seamless transitions from cryogenic conditions (3.5 K) to elevated temperatures up to 400 °C on the same platform.

High-Temperature and Cryogenic Capability

Closed-loop cryogenic and high-temperature chambers allow continuous testing across an exceptionally wide temperature range—from 3.5 K to 400 °C, with an optional high-power heating configuration up to 1000 °C—without changing systems or test setups.

Environmental Atmosphere Control

The vacuum chamber supports testing in ultra-high vacuum as well as controlled inert gas atmospheres, enabling vacuum tribology studies under application-specific environmental conditions for aerospace, space, semiconductor, and advanced materials research.

Unmatched Load Cell Technology

Capacitive Force Sensor

Equipped with a patented multi-dimensional capacitive force sensor, the MVT-2 vacuum tribometer delivers exceptional force resolution and long-term stability for vacuum tribology applications. Moreover, this sensing technology enables accurate friction and wear measurements under ultra-high vacuum conditions. In addition, a wide force range from mN to 200 N allows seamless testing of delicate thin films as well as bulk materials on the same vacuum tribometer platform.

Ultra-High Force Resolution

Ultra-high force resolution enables detection of subtle changes in friction and wear behavior during testing.

Long-Term Signal Stability

Negligible signal drift over extended test durations and across wide ranges of load, temperature, and vacuum conditions.

Calibrated Accuracy

Calibrated to traceable standards, ensuring consistent and repeatable results across tests and laboratories.

Wide Test Range

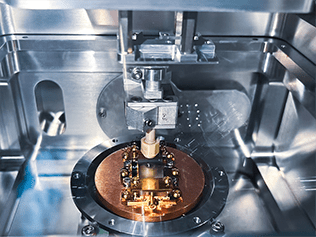

2D Materials and Thin Film Testing

Rotary test configurations enable precise measurement of friction and wear in 2D materials, thin films, and ultra-thin coatings. This setup is ideal for nano-scale vacuum tribology studies, where extremely low forces and high sensitivity are required.

Extreme Cryogenic Testing

A closed-loop liquid-helium cryogenic architecture supports sustainable, near zero-loss operation for testing friction, wear, hardness, and scratch resistance under extreme cryogenic conditions. This configuration is well suited for space, cryogenic engineering, and low-temperature materials research.

Vacuum Grease and Lubricated Surface Testing

Rotary configurations designed for bulk materials and lubricated surfaces enable evaluation of friction behavior in vacuum environments. This setup supports micro- and macro-scale vacuum tribology, including testing of vacuum-compatible greases and solid lubricants.

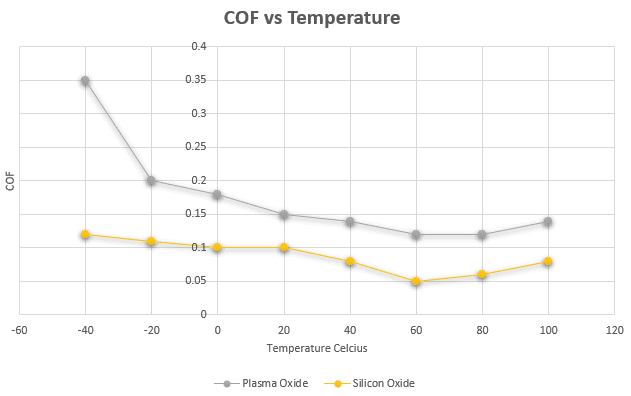

Vacuum Tribology Test Data

Sample 1 – the plasma oxide treatment.

Sample 2 – silicon oxide treatment.

- 10 N force

- Velocity 4 mm/s

- Acceleration at 0.1 mm/s2.

- 10-6 Torr

Vacuum Tribology Solution

Engineered for tribology testing in ultra-high vacuum environments, the MVT-2 vacuum tribometer enables precise control of load, speed, and temperature for detailed analysis of friction, wear mechanisms, and material behavior in vacuum. For this reason, it is ideal for studying friction, wear mechanisms, and material behavior in vacuum for a variety of applications.

-

Space

-

Aerospace

-

Advanced Materials

-

Semiconductor

-

Quantum Computing

The MFT-5000 Has More To Offer

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved