3D Scratch Testing With The MFT Series Overview

Main Features:

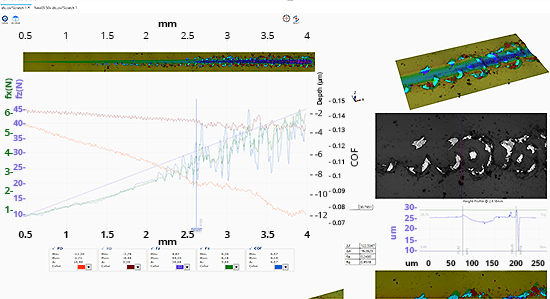

- 3D Profiler and scratch data automatic correlation

- Nano scratch, micro scratch, macro scratch on same tester

- High repeatability because of rigid design

- Automatic reports

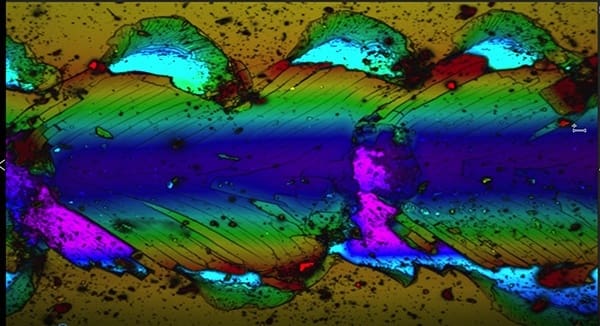

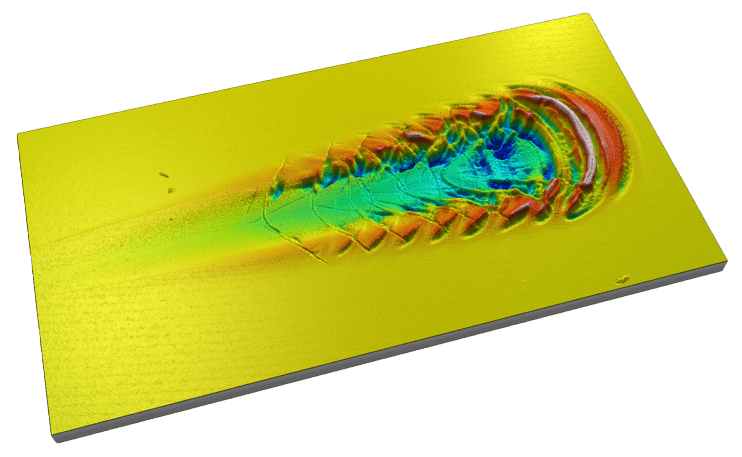

The 3D Scratch Test module quantifies coating substrate systems. It measures scratch adhesion, scratch hardness, and marr resistance at nano, micro and macro scale. In-line integrated 3D profilometer allows to analyze failures with high resolution. The profilometer correlates effect of roughness, features, and more, on the measured properties. Advanced patented capacitive sensors measure force and penetration depth with resolution needed to differentiate coatings at any scale.

Need help or have a question?

Learn More About The Platforms

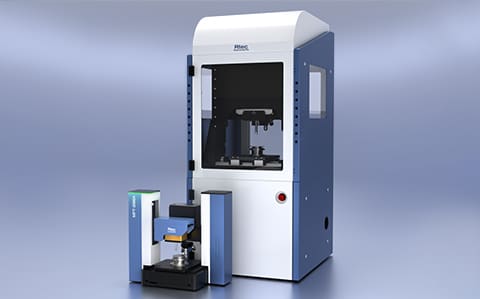

The MFT Series Tribometers

Explore our MFT Series Tribometers for versatile surface and material testing.

Coatings Adhesion, Scratch, and Mar Resistance

The scratch test quantifies the adhesion and scratch hardness of coatings. Thinner coatings are finding their way into every aspect of our life with new deposition methods and technologies. Coatings are applied to LCD displays, phones, cutting tools, gems, glass, automobiles, and medical devices. Quantitative coating adhesion scratch testing is a simple, practical test that the MFT tribometers provide for comprehensive coating scratch testing evaluation.

Friction, Wear, and Coating Failures Data Correlation

Pre Test Image

Sample moves under 3D profilometer to measure surface topography

Scratch test

Single or multiple scratches using predefined recipes are performed

Post Test Image

The sample moves under the profilometer to analyze scratch area

Report

Automatic image, adhesion, friction, depth, and roughness correlation reports are created.

3D Scratch Test nm to mm, Thick Coatings, and High Temperature

A scratch test requires applying a load on the sample that needs testing with a spherical or custom tip. During load application, the sample moves at a constant velocity and several parameters such as Friction (Fx), Down force (Fz), Coefficient of friction (COF), displacement (Z), acoustic emission (AE), and temperature are measured in situ.

Sensors and Chambers

Application specific solutions

Environmental chambers and a variety of sensors create numerous test variations that replicate real-life scenarios.

Sensors

Various sensors on coating scratch adhesion tester allows gathering of more information during the test.

Electrical Contact Resistance

Measure point of coating failure by looking at resistance change during the scratch.

Acoustic Emission

Measures sound signal during the scratch, that may point to onset of coating failures.

Potentiostat

Provides scratch corrosion studies.

Environmental Chambers

Temperature, Humidity, and More.

Scratch Setup With In-line Profiler

Scratch With Rockwell Tip

Scratch With Cutting Tool

The Scratch Test Solution

Due to multiple configurations, the MFT Series is used extensively across a wide range of industries:

Aerospace

- Thermal Spray Coatings

Automotive

- Marr Resistance, Scratch Adhesion

- Thermal Spray Coatings

Bio-materials

- Scratch Resistance

Ceramics

- Scratch Resistance

Hard Coating

- Scratch Resistance

Metal

- Scratch Hardness

- Scratch Resistance

Optics and Glasses

- Scratch Resistance

Pharmaceutical

- Scratch Resistance

Polymer

- Scratch Resistance

Semicon

- Scratch Resistance

Need Focused Indentation and 3D Scratch Testing?

Take a look at Rtec-Intstruments’ Indentation and Scratch Tester, the SMT-5000.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved