Fretting Tester Overview

Main Features:

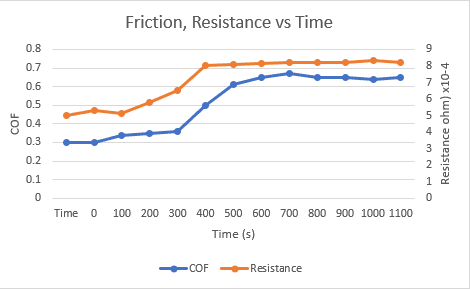

- Simultaneous electrical, wear, and friction measurement

- Experience strokes as precise as a few micrometers to several millimeters

- Fretting simulations ranging from a few Hz to 500 Hz oscillation

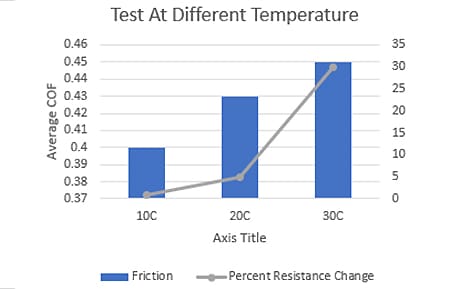

- Dry or lubricated environmental conditions from -40°C to 400°C

With constant use, varying hot and cold environments, and micro-motion, electrical connector fretting failure is a constant challenge among many industries. Rtec-Instruments’ FFT-M Fretting Tester quickly assesses the tribological properties of materials and coatings, making it invaluable for evaluating connector materials’ friction and wear characteristics. This advanced benchtop tester takes a specialized approach and offers real-time monitoring of current, voltage, wear, and corrosion measurements under controlled temperature and humidity conditions. By employing state-of-the-art electromagnetic actuators, piezo force sensors, and voice-coil technology, it empowers engineers to replicate and study fretting corrosion scenarios comprehensively. With the FFT-M, industries can make informed decisions regarding connector materials, coatings, and lubrication strategies, ending electrical connector fretting wear and fortifying connections for a more reliable future.

Need help or have a question?

Learn More About The Platform

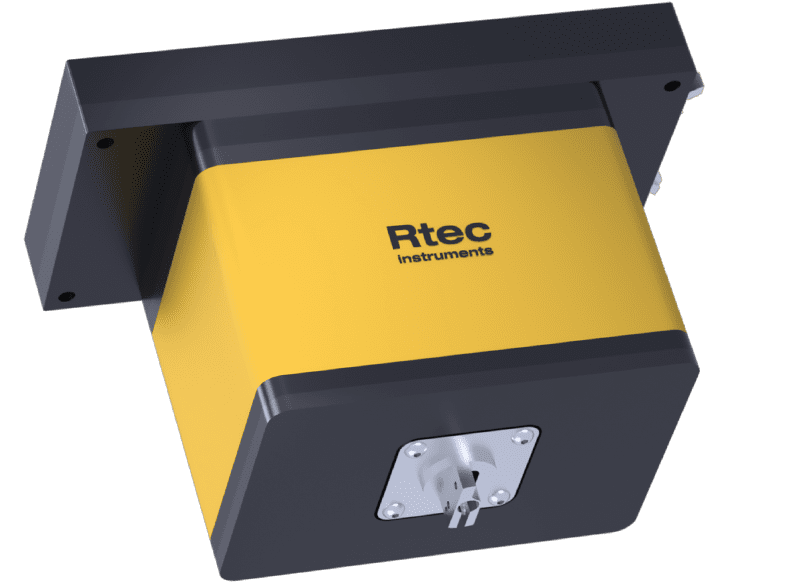

The FFT-M Fretting Tester

Explore our Benchtop FFT-M and how it supplies precise fretting analysis in dry, lubricated, and humid environments.

Watch Electrical Connector Fretting Wear Testing in Action

Ultra High Resolution Fretting Wear Analysis

Friction and Wear Analysis You Can Count On

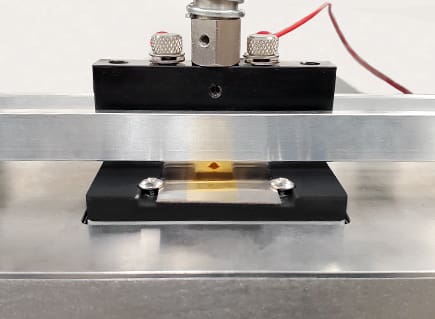

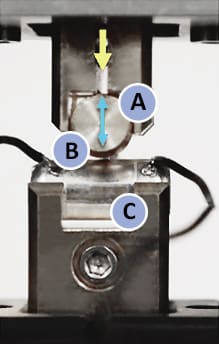

Electrical Connector Fretting Test Setup

Load

Frequency

CuZn37 connector under fretting (upper connector)

Tribo-interface

Stationary pure Ag-coated connector (lower connector)

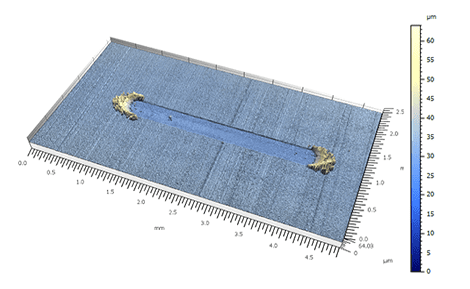

Patented Integrated In-line 3D Profilometer

Our 3D profilometer creates nm-level 3D surface change plots automatically during testing. This feature enables easy correlation of the lubricity and friction data with surface topography. The lambda head model combines four optical techniques on one head – interferometer, spinning disk confocal, dark field, and bright field imaging. It can easily measure the electrical connector’s surface – transparent, rough, smooth, and steep slopes surface. With an in-line profilometer, automatic stitching of volume wear and roughness calculations are now possible. Additionally, the 3D profilometer’s high-resolution imaging and analysis software makes it easy to analyze and optimize electrical connector surfaces and materials.

Unmatched Load Cell Technology

Capacitive Sensors 0.001 COF accuracy

The electrical connector fretting tester comes with a wide range of load cells, providing unparalleled stability and resolution. Force sensors are easily interchangeable to cover a wide range of test conditions. Depending on the configuration, forces are measured in 1, 2, or 6 axes.

Capacitive Load Cells

Highest resolution load cells with high rigid design

Piezo Actuators

Highest resolution precise motions

Traceable Forces

Calibrated with traceable standards

1D, 2D and 6D sensors

Sensors to measure forces in all directions during the motion

The Electrical Connector Fretting Failure Testing Solution

Due to the versatility of the FFT-M fretting tribometer, it is used extensively across a wide range of industries:

- Data Centers

- Renewable Energy

- Phones and Tablets

- Power Distribution Systems

- Aviation

- Automotive

- Medical Devices

- Telecommunications

- Industrial Manufacturing

- Research and Development

- Transportation

The MFT-5000 Has More To Offer

Need Compact Fretting Analysis?

Take a look closer look at Rtec’s Benchtop Fretting Tester, the FFT-M.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved