Detailed Module Information

Main Features:

- Programmable close loop force up to 10,000 N (No Dead Weights)

- -35 °C to 200 °C (400 °C) Temperature

- Automatic EP and Wear

- In-line Torque, Acoustic signal, Down force

- ASTM, DIN, ISO Compliant

The 4-ball wear tester is used to determine the extreme pressure properties (EP), weld force, coefficient of friction, ball diameter and load-wear index (LWI) of formulated lubricants and wear-reducing additives for greases and oils.

Each MFT-5000 next generation 4-ball tester is an excellent option to run multiple 4-ball tester standard tests on the same platform. The tester comes with closed-loop down force control. This allows for up to 10,000 N load using advanced motors and no dead weights. 4 ball wear or 4 ball EP tests are automatic and very easy to use.

In-line torque, friction, and acoustic signals automatically calculate the test results. The tester also creates quick screening methods. For example, applying linear loads instead of step loads.

Highly versatile, wide temperature and test range, fully automatic, and computer control, make this four ball tester highly repeatable and very easy to use.

Need help or have a question?

Learn More About The MFT-5000 Platform

The MFT-5000 Tribometer

Learn more about the versatile MFT-5000 tribometer that provides friction, wear, and surface properties of various materials and coatings under a multitude of fluids, environments, and testing conditions.

Multiple Standard Tests

ASTM D2266, D4172, ASTM D2596, ASTM D2783, BS EN ISO 20623, BS ISO 26422, CEC L-45-A-99, DIN 51 350, IP 23.

Wear Protective Test

This test evaluates lubrication performance of grease or oil. The test is carried out at relatively mild test conditions. For example, 392 N at 75°C at 1200 rpm for 1 hour. The performance of the lubricant is evaluated by measuring and comparing the wear diameter of the balls after the test. Diameter of wear scar on each of the three lower balls are measured at two locations 90° to each other. The average of six measurements is reported as wear diameter for the 4 ball test. The four ball testing machine gives high reproducible results during the wear test as the down force is precisely controlled in real-time.

Extreme Pressure EP Test

The 4 ball EP test is used to test lubrication properties of lubricants (oils and greases) under extreme pressure conditions. The top ball rotates at high speeds and high loads for a short duration of time. For example, 1800 RPM, 3000N and 30s. Load increase in steps or linearly until the lubricant fails. The maximum load available is up to 10,000 N. The failure is determined by welding of the four balls, visible smoke, instantaneous increase in friction or torque. The test is automatically stopped at the onset of failure. The lubricants are rated based on their ability to “pass” the test without failure at applied loads.

4-Ball Tester Data and Analysis

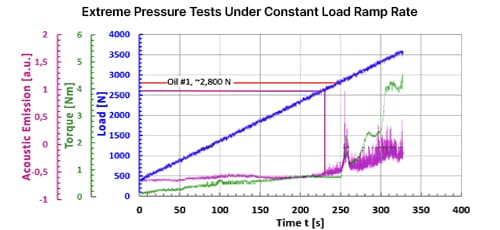

Quick screening test to evaluate extreme pressure properties.

Figure 1

Figure 1 shows the results of a new test with continuously increasing load. The test was configured to apply a linearly increasing load from 400 N to 4000 N. The acoustic signal measured in parallel (purple) indicates that the loss of function begins even slightly earlier than approximately 2800 N. The acceptable load based on the coefficient of friction (green) is 2800 N. Complete failure, leading to welding, was observed at approximately 3600 N. During the test, the coefficient of friction was measured in real time and recorded with high precision.

Figure 2

Figure 2 shows the 3D Image of the ball scar. The Rtec Universal Lambda 3D Profilometer created the 3D wear profile. The profilometer shows both volume wear loss and scar diameter or rotating or stationary balls creating using various test methods.

Solution To

The 4 Ball Tester is used extensively across a wide range of industries for a variety of lubrication testing needs:

-

Automotive Industry, Mobility

-

Aerospace

-

Lubricants – Base Oils, Additives, Formulators

-

Mechanical Engineering

The MFT-5000 Has More To Offer

Take a closer look at the Multi Function Tribometer.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved