Polymer Testing

Rtec Instruments provides several standard and customized test solutions to evaluate polymer materials and polymeric coatings across many applications. With many testing solutions, we offer comprehensive analysis that aids in all stages of polymer manufacturing and research.

Solutions We Offer for the Polymer Industry

We offer a variety of instruments to cover all the bases. Whether it’s studying scratch resistance in polymers research, or 3D imaging polymer failure during manufacturing, we have the right system.

Scratch Adhesion, Resistance, Hardness

Using polymers is common in many consumer and industrial areas. They have several advantages, such as low density, chemical resistance and easy production. However, polymers have lower wear and scratch resistance. Therefore, One must monitor these properties carefully.

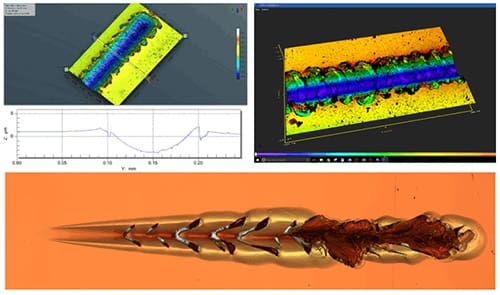

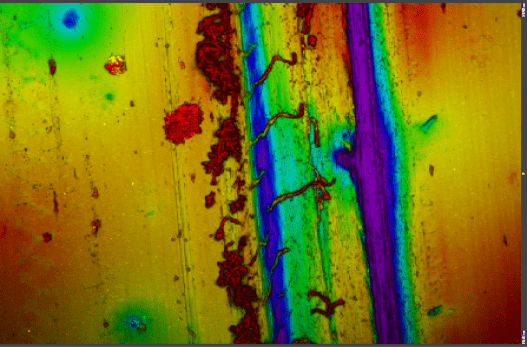

Study scratch adhesion, hardness, scratch resistance, and wear of polymer coatings or materials at nano, micro and macro scale. In-line integrated 3D profilometer provides 3D stitched images to comprehensively and conclusively characterize the failures.

Friction and Wear

The understanding of friction of polymers is of increasing importance because of the various new applications across several industries, such as healthcare, automotive, aerospace, and consumer goods.

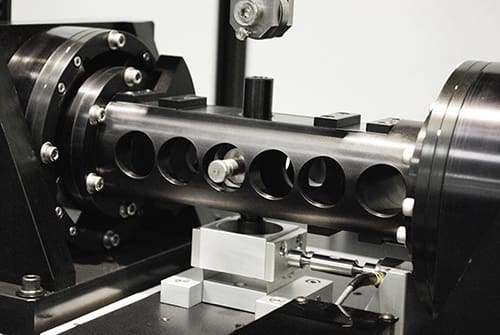

Perform tribology, friction, and wear studies of coatings, materials and finished components under a wide test load range, motion, and various controlled environmental conditions.

Fretting Wear Test

The central role of polymers in the development of functional materials is fueled by advanced production of well-defined and optimized polymers. To study degradation due to fretting, wear, and corrosion, Rtec Instruments provides unequaled specifications for fretting tester. Our fretting testers provide controlled strokes from 5 microns to several mm, up to 500 Hz frequency. All can be performed during a variety of controlled environmental conditions.

3D Imaging

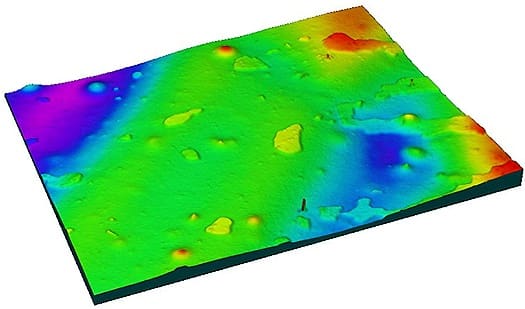

Polymer is a unique category as the final product can be with colors, transparent, various shapes, steep slopes, flat, dark, and multiple layers. To characterize surface polymers effectively, Rtec Instruments has a unique solution.

The universal profilometer combines 4 imaging modes (confocal, interferometer, dark field and bright field) in one head. This is very beneficial for the polymer industry as advantages from seamlessly using all techniques allow measurement of any form of polymer using one optical profilometer.

Polymer Materials Testing Solutions In Action

Watch as we demonstrate how our instruments can fulfill all of your polymer testing applications.

Need Versatility?

Take a closer look at the Multi Function Tribometer.

Need Fretting?

Check out our FFT Fretting Testers Series

Need Indentation and Scratch Testing?

Learn more about our Indentation and Scratch Tester, the SMT-5000.

Need 3D Microscopy?

Check out new line of 3D Optical profilometers, the UP Series.