Fretting Test Module Overview

Main Features:

- 5 micron to 4mm Stroke

- Up to 300 Hz

- Piezo Sensors

- Friction up to Electromagnetic Coils

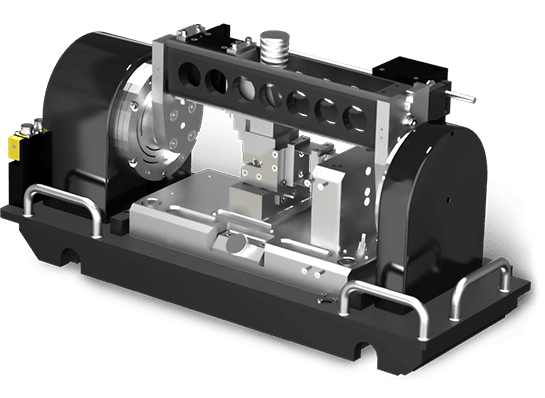

Rtec Instruments’ MFT-5000 provides fretting analysis for many applications. For example, common applications include the testing of materials, lubricant, grease, and coatings. The state-of-the-art fretting module has industry-leading specifications on stroke and frequency. With a controlled stroke from 5 microns at 300 Hz frequency, and a wide temperature range, the MFT-5000 is an ideal fretting wear material property tester for industry and university research.

Need help or have a question?

Voice Coil With Real Time Stroke Control

Technology breakthroughs in voice coil control and high-frequency signal processing algorithms provide fretting wear tests with less than 5-micron stroke. These features also characterize fretting wear from micron to macro scale. In addition, ultra-sensitive piezo-based load cells, combined with a robust design, high stiffness holders, and low floor noise, allow quantitative fretting wear characterization of materials, interfaces, thin films, components, and more.

The Smallest Controllable Stroke - 5um to 4mm, up to 300Hz

Real-time stroke, frequency monitoring, and correction using LVDT.

High Reliability - Flexure Design

The flexural suspension guides the magnet assembly without

bearings.

Environmental Control, Surface Electrical Measurement

Humidity, temperature, inert gas, and electrical measurements for

real-life simulation.

High Frequency Response Force Sensors

Piezo-based sensors measure friction force with ultra high accuracy at a high-frequency reciprocating test.

High Speed Controllers

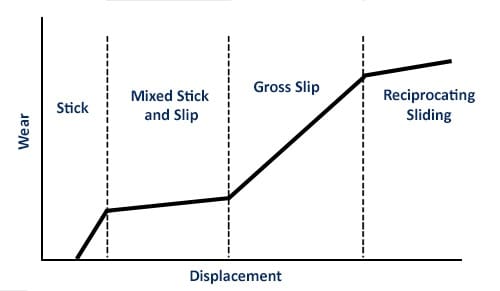

The Fretting Module Is perfect for testing surface damage that occurs between two contacting surfaces experiencing oscillatory displacement of a small amplitude.

Test Debris

- Debris formation from asperity contacts

- Oxidation at contacting surface because of humidity, temperature, or chemical composition change

- Oil, lubrication starvation regimes causing wear

- Wear due to electric discharge

- Repetitive collision between surfaces

- Fatigue related cracks – onset of debris

- Polymerization of organic materials at surface

- Fine powdered debris – highly oxidized

- Residual steady stage flow of debris

- Diffusive wear

- Melting wear

Specification Summary

Reliable and Customizable

To simulate real life scenarios, tests can be done in controlled environmental conditions. Easy to use and intuitive data interpretation makes this tester an ideal tool in hands of researchers or quality control engineers.

Actuators

- Displacement 5um-4mm

- Resolution: 0.1um

- Oscillation frequency: Up to 300Hz

Environmental

- Temperature control

- Humidity controlled chamber

Sensors

- Potentiostat

- Acoustic Emission

- Electrical Contact Resistance

Common Standards

- ASTM E2789

- ISO 19291

- ASTM D6425

- ASTM D7421

- ASTM D5707

- ASTM D5706

- ASTM D7594

- DIN 51834-2

- DIN 51834-3

- DIN 51834-4

Solution To

Due to multiple configurations, the MFT-5000 fretting module is used extensively across a wide range of industries:

Aerospace

- Wear Resistance

- Fretting

- Thermal Spray Coatings

- High Temperature

Automotive

- Fretting and Wear Resistance

- Engine Related Tests

- Tribology, Friction, and Wear

Bio-materials

- Corrosion

- Fretting

Ceramics

- Wear Resistance

- Fretting and Friction Testing

Lubricants

- HFRR

- Wear Resistance and Friction

Metal

- Fretting

- Tribology and Friction Testing

Optics and Glasses

- Fretting and Wear Resistance

Pharmaceutical

- Wear and Friction

Semicon

- Fretting

- Wear Resistance

- Tribology and Friction Testing

Need More Fretting Options?

Take a look at Rtec’s Fretting Testers.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved