3D Scratch And Indentation Tester Overview

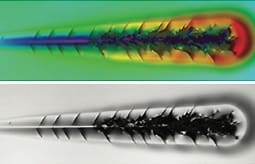

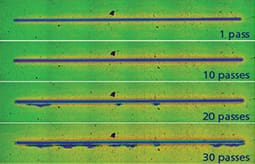

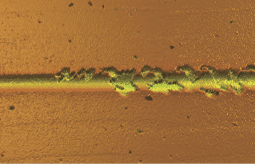

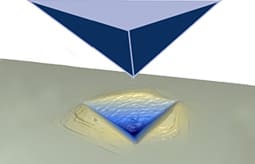

- Patented In-line 3D Profilometer

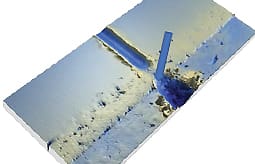

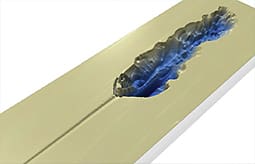

- Nano scratch, Micro scratch, Macro scratch

- Optimized 3D profilometer at nm resolution for any surface

- Scratch Flat or curved surface

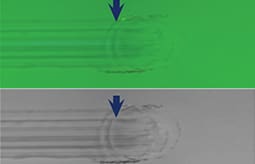

The indentation and scratch testers analyze scratch adhesion, hardness, modulus, and scratch resistance. It provides analysis at nano, micro, and macro scale.

In addition, the in-line integrated profilometer provides 3D stitched images. These images characterize the coating failures. Advanced capacitive sensors measure penetration depth. They provide measurements with the resolution needed to differentiate coatings with similar properties.

For this reason, Rtec-Instruments has developed a simple method to test coating adhesion for various applications. Examples are wear resistance on cutting tools, the film thickness on transparent lenses, or the hardness of automotive coatings.

Need help or have a question?

3D Indentation and Scratch Testing Applications

Click below to take a closer look at case studies and applications utilizing with the Rtec Instruments’ 3D Indentation and Scratch Tester, SMT-5000.

Solution To

Because the indentation and scratch adhesion testers are so diverse, they provide analysis across a wide range of industries:

Aerospace

- Thermal Spray Coatings

- Turbine, engine, components

- Anti corrosive coatings

Automotive

- Marr Resistance

- Thermal Spray Coatings

- DLC

- Paints

Bio-materials

- Bio compatible coatings

- Medical devices

- Joints

- Valves, pumps

Ceramics

- Ceramic coatings

- Bulk materials

Hard Coating

- Cutting tools

- Thermal spray

- DLC

Metal

- Bulk Materials

- Coatings

- Textured surfaces

Optics and Glasses

- Lenses

- Touch screen

- Consumer goods

Pharmaceutical

- Coatings on tablet

Polymer

- Marr resistance

- Coating

- Bulk materials

Semicon

- Screens

- Thin coatings

- Protective coatings

- Consumer goods

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved