ASTM D2509-14

Measurement of Load-carrying Capacity of Lubricating Grease

Timken Method

The ASTM D2509-14 test method is used to differentiate between greases having low, medium, or high levels of extreme pressure characteristics.

Summary of the ASTM D2509-14 Standard

This test method covers the determination of the load carrying capacity of lubricating greases by means of the multi-functional tribometer MFT-5000.

Two determinations are made: the minimum load (score value) that will rupture the lubricant film being tested between the rotating cup and the stationary block and cause abrasion; and the maximum load (OK value) at which the rotating cup will not rupture the lubricant film and cause abrasion between the rotating cup and the stationary block. The loads are determined by visual inspection of the stationary block for adhesive wear.

Timken Test Parameters

| Test Blocks: | Carburized steel, having a Rockwell Hardness C Scale Number of 58 to 62 |

| Normal Load: | Until failure |

| Test Duration: | Until Failure |

| Temperature: | Ambiant (21 – 24 °C) |

| Speed: | 800 rpm |

| Lubrication: | Test Grease |

| Data Collection: | Normal Force (Fz) In-line Torque (Tz) Coefficient of Friction Temperature |

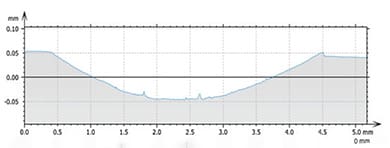

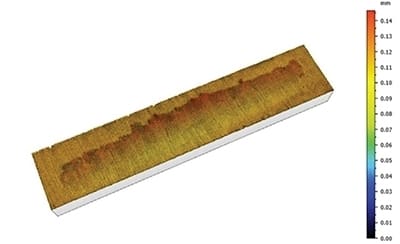

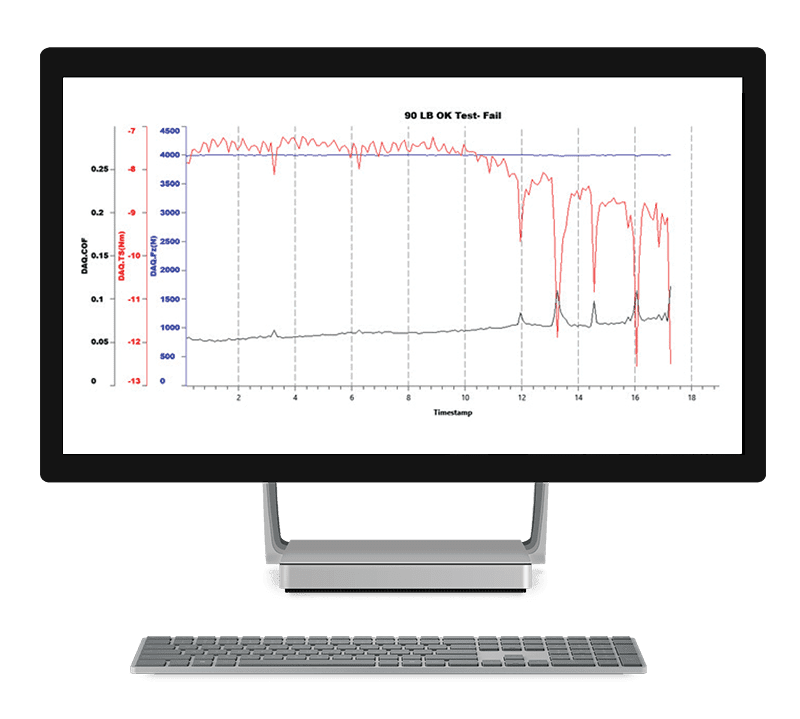

Data Summary

Representative test results to show failure of the grease is shown below. The test is stopped automatically as the torque reaches a pre-defined failure value. The MFT-5000 quickly provides the load-carrying capacity of the lubricating grease.

| Parameters | value | Unit |

|---|---|---|

| Length | 5.1712 | mm |

More on the Multi Function Tribometer (MFT-5000) Hardware

- Load sensor (1000 N)

- Block on Ring Drive

- Temperature chamber

- Block holder

- Liquid container for block on ring drive

- Integrated 3D profilometer

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved