ASTM G99-17

Wear Testing with a Pin-on-Disk Apparatus

International Tribology Standard

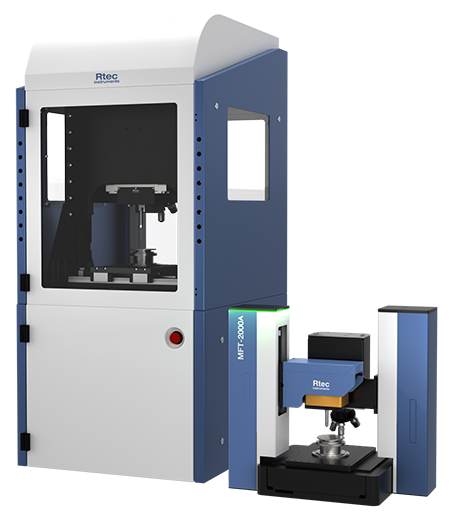

Perform wear testing with the pin-on-disk ASTM G99-17 method using the Multi Function Tribometer. This method is for wear testing metals, polymers, ceramics, composite materials, hard coatings, and much more.

Summary of the ASTM G99-17 Standard

For the pin-on-disk wear test, two specimens are required. One, a pin or ball that is positioned perpendicular to the other, usually a flat circular disk. The test involves a stationary ball to wear against a rotating disk at a controlled force and speed.

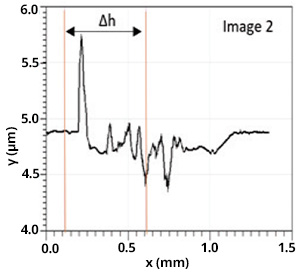

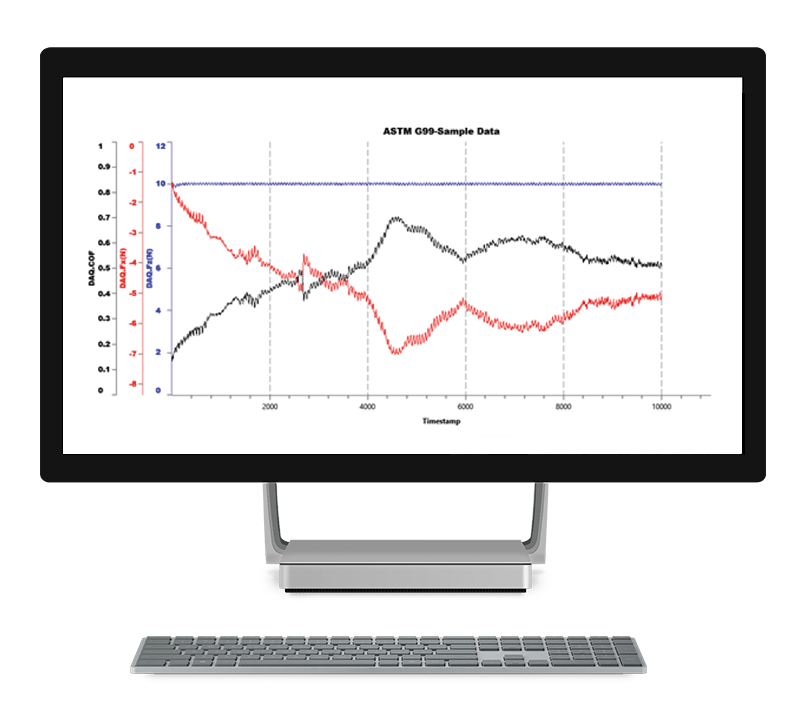

During the test COF, friction force, wear etc. parameters are measured. The ball and disc wear volume is calculated from the ball and disc wear radius and width respectively.

Wear Test Parameters

| Load: | 10 N |

| Speed and Velocity: | 0.1 m/s |

| Environment: | Room Temperature (~23 °C) Humidity (12-78%) |

| Test Duration: | 2.77 hours or 1,000 m of sliding distance |

| Data: | Friction Force (Fx) Normal Force (Fz) Rotary Velocity (T) Vertical Displacement (Z) Coefficient of Friction COF Acoustic Emission AE |

Data Summary

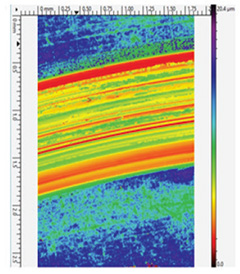

The data also shows 3D image of the wear mark on lower sample.

| Test # | Average COF at A | Average COF at B | Average COF at C |

| 1 | 0.66 | 0.65 | 0.59 |

| 2 | 0.61 | 0.64 | 0.51 |

| 3 | 0.63 | 0.65 | 0.60 |

| 4 | 0.66 | 0.61 | 0.62 |

| 5 | 0.61 | 0.65 | 0.61 |

| 6 | 0.63 | 0.64 | 0.60 |

| 7 | 0.62 | 0.60 | 0.64 |

| 8 | 0.61 | 0.62 | 0.52 |

| 9 | 0.63 | 0.65 | 0.59 |

| 10 | 0.64 | 0.66 | 0.64 |

| Average | 0.63 | 0.63 | 0.61 |

More on the Multi Function Tribometer Series Hardware

- Load sensor (N)

- Friction sensor (20 N)

- The typical pin specimen is cylindrical or spherical in shape. Typical cylindrical or spherical pin specimen diameters range from 2 to 10 mm.

- Universal ball holder

- 52100 steel ball – 6 mm

- Stainless Steel Disk (2 inch)

- Lower rotation drive

- Optional additional sensors

- Integrated 3D optical profilometer (for volume wear) on MFT-5000 and MFT-2000A platforms

- Temperature in option

- Humidity in option

- Acoustic emission in option

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved