ASTM D4172-94

Wear Preventive Characteristics of Lubricating Fluid

Four-ball Method

Determine the relative anti-wear properties of fluid lubricants in sliding contact with the 4-ball ASTM D4172-94 standard method.

Summary of the ASTM D4172-94 Standard Method

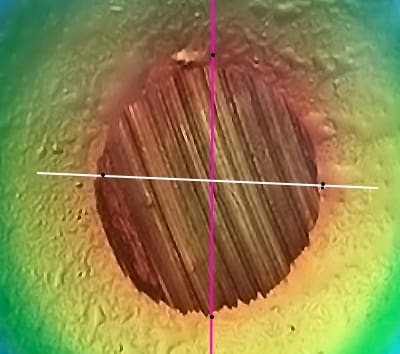

The ASTM D4172-94 test method covers a procedure for making a preliminary evaluation of the anti-wear properties of fluid lubricants in sliding contact. A steel ball is rotated under load against three stationary steel balls submerged under test lubricant. The average diameters of the wear scars on the stationary balls are measured after completion of the test and are used as an indicator for wear preventative characteristics of the lubricant.

Lubricant Wear Test Parameters

| Balls: | AISI standard steel No. E-52100 Grade 25 EP |

| Ball diameter: | 12.7 mm |

| Normal Force: | 15 or 40 Kgf |

| Test Duration: | 60 minutes |

| Speed: | 1200 rpm |

| Temperature: | Ambiant (75 °C) |

| Lubrication: | Lubricating Liquid |

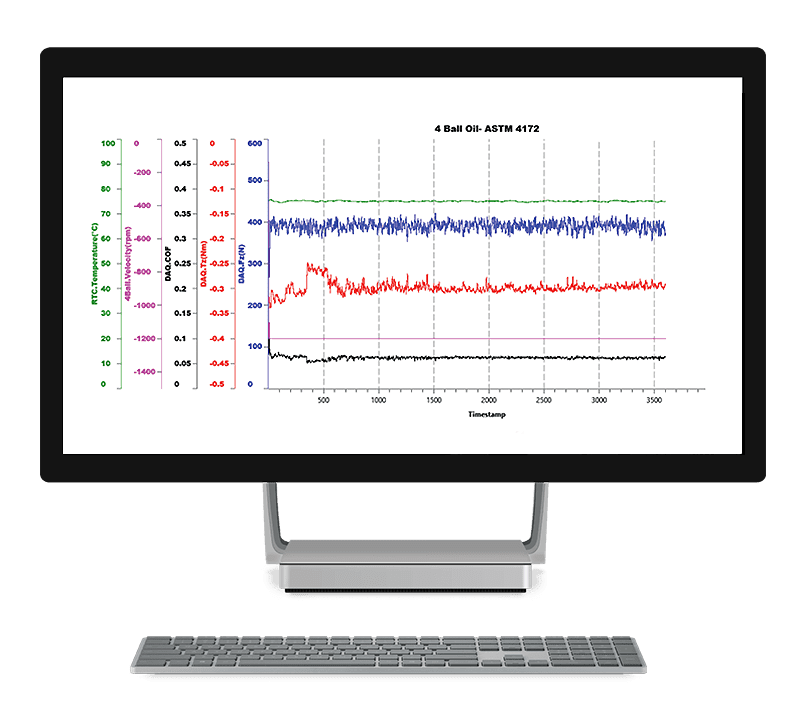

| Data: | Torque (Tx) Normal Force (Fz) Frequency (Hz) Temperature (°C) Humidity |

Anti-wear of Lubricants Data Analysis

The lubricity test results are quickly reported. The load at which the balls weld together is reported along with the wear scar diameter in the final report.

More on the Multi Function Tribometer (MFT-5000) Hardware

- Quad force load sensor (10,000 N)

- Torque sensor (22.6 Nm)

- Upper rotary module

- Four-ball module container assembly

- Temperature chamber

- Integrated 3D profilometer

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved