ASTM D2596

Measurement of Extreme Pressure Properties of Lubricating Grease

Four-ball Method

Perform EP tests with the Four-ball ASTM D2596 method using the Multi Function Tribometer.

Summary of the Standard

extreme pressure conditions.

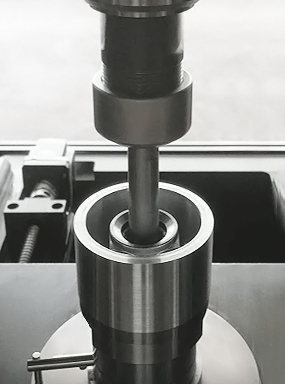

Rtec-Instruments Multi-function Tribometer (MFT-5000) with Four-Ball extreme pressure module can be used to evaluate wear and erosion resistance of test greases.

The test is performed by rotating a ball against three balls in a container packed with the test grease at various contact pressures till failure is observed. Three determinations are made and reported:

- Load-Wear Index

- Weld Point, by means of the Four-Ball Extreme Pressure (EP)

- Last non-seizure load (LNSL).

Parameters

| Balls: | Steel Balls material AISI standard steel E52100 Grade 25 EP (100Cr6) |

| Ball diameter: | 12.7 mm |

| Normal Force: | Step increasing load (6, 8, 10, 13,16, 20, 24, 32, 40, 50, 63, 80, 100, 126, 160, 200, 250, 315, 400, 500, 620, 800) Kgf* |

| Test Duration: | 10 seconds for each step |

| Speed: | 1770 rpm |

| Temperature: | Ambiant (23 °C) |

| Lubrication: | Grease applied |

| Data: | Torque (Tx) Normal Force (Fz) Rotation Speed (rpm) Temperature (°C) Acoustic Emission AE |

ASTM D2596 Standard Set-up

These tests are done using Rtec-Instruments Multi Functional Tribometer MFT 5000. During the test in-line torque, down force, acoustic emission, electrical contact resistance and temperature values are recorded and reported.

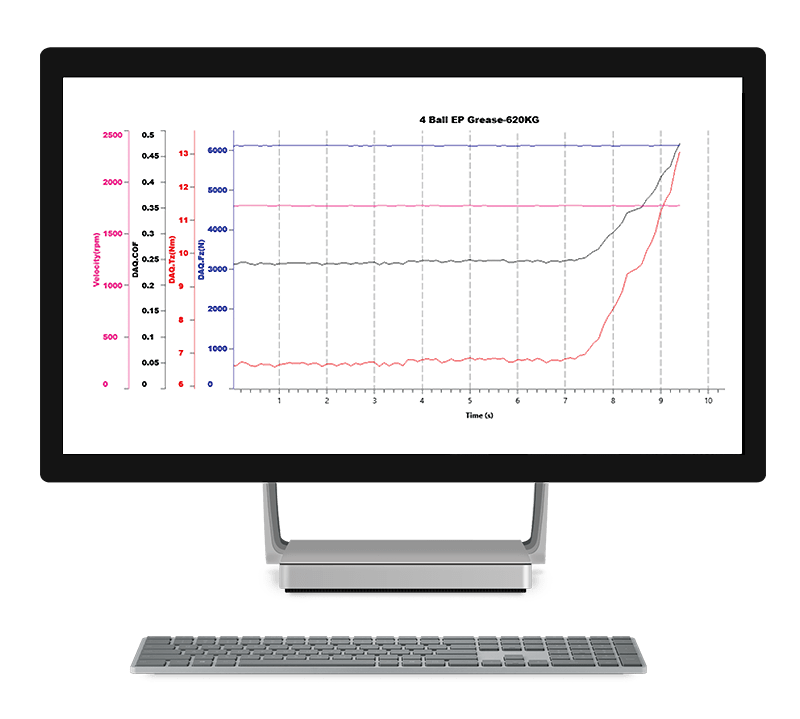

The test involves increasing load in steps of 10 seconds each till the balls are welded representing abrasive wear. The linear loading mode of MFT-5000 tester also allows to run the same test in one step by applying a linearly increasing force at a controlled rate instead of multiple steps at constant load. This can be used as an efficient, high through put method of grease analysis.

Data Summary

Representative test results are reported below indicating failure at 620 Kg. The load at which the balls weld together, and the last non-seizure load is reported.

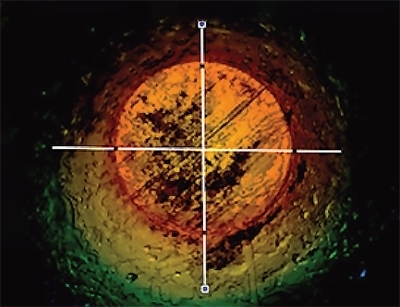

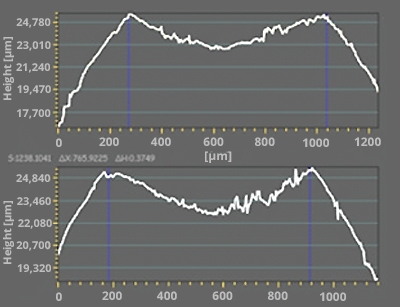

The load wear index is calculated by measuring the wear scar diameters on the lower three balls. Other tribological properties such as friction coefficient and acoustic emission can also be measured real time.

More on the Multi Function Tribometer (MFT-5000) Hardware

- Quad force load sensor (10,000 N)

- Torque sensor (22.6 Nm)

- Upper rotary module

- Four-ball module container assembly

- Temperature chamber

- Integrated 3D profilometer

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved