ASTM D2266

Wear Preventive Characteristics of Lubricating Grease

Four-ball Method

Perform wear and erosion testing with the Four-ball ASTM D2266 method using the Multi Function Tribometer. This method is for lubricating greases in sliding steel-on-steel only.

Summary of the ASTM D2266 Standard

This note describes a commonly used wear test method for grease testing.

It covers the determination of the wear preventive characteristics of lubricating greases in sliding steel-on-steel applications.

It is not intended to predict wear characteristics with metal combinations other than steel-on-steel.

This test method is not used to evaluate the wear rate or extreme pressure characteristics of the grease.

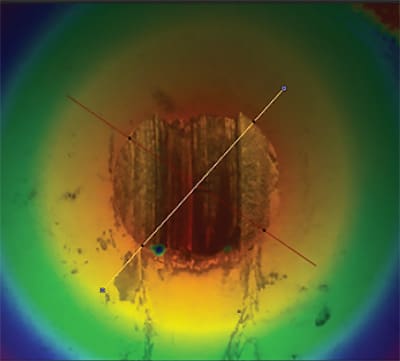

A steel ball is rotated under load against three stationary steel balls having grease lubricated surfaces. The average diameters of the wear scars on the stationary balls are measured after completion of the test.

Wear Test Parameters

| Balls: | Steel Balls material AISI standard steel E52100 Grade 25 EP (100Cr6) |

| Ball diameter: | 12.7 mm |

| Normal Force: | 392 N |

| Test Duration: | 60 minutes |

| Speed: | 1200 rpm |

| Temperature: | 75 °C |

| Lubrication: | Test Grease |

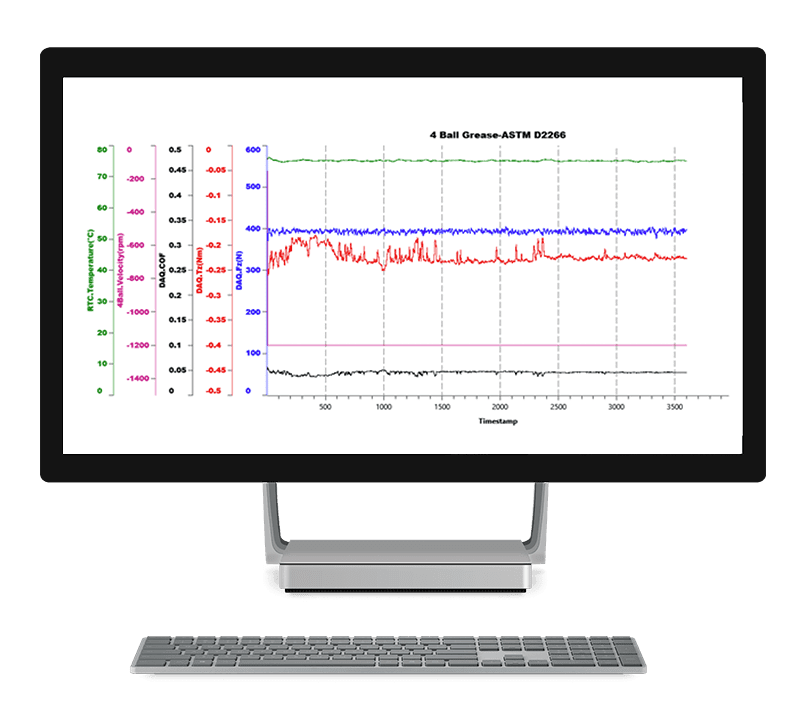

| Data: | Torque (Tx) Normal Force (Fz) Rotation Speed (rpm) Temperature (°C) Acoustic Emission AE |

Data Summary

The quantitative information measured on Rtec-Instruments MFT-5000 Four Ball set up provides insights into the lubrication and wear resistance performance of the greases.

The average wear scar diameter of the three lower balls is reported in the final report.

More on the Multi Function Tribometer (MFT-5000) Hardware

- Tri mode Load sensor (1000 N)

- Torque sensor (22.6 Nm)

- Upper rotary module

- Four-ball module container assembly

- Temperature chamber

- Integrated 3D profilometer

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved