Fretting Wear Tester Overview

- 10 µm to 2.8 mm Stroke

- 1 to 300 Hz frequency

- High frequency piezo Sensors

- Electromagnetic Coils

Why Fretting Tests? Small oscillatory motion between contacting surfaces causes accumulation of wear debris in the contact zone. Thus greatly speeding up the wear process. Several applications such as aerospace, automotive, machinery, displays, and medical devices commonly observe fretting wear.

Rtec Fretting Solution – The state-of-the-art fretting wear testers provide unequaled specifications of stroke and frequency in the industry. Controlled stroke from 10 microns and frequency up to 300 Hz frequency makes it an ideal fretting tester for both industry and university research.

Need help or have a question?

A Fretting Machine Like No Other

Test the surface damage that occurs between two contacting surfaces. Analyze two-body abrasion, adhesion, and/or fretting fatigue wear.

Down Force Control

Real time down force control to account for contact wear.

Voice Coil

Electromagnetic actuator that imparts linear reciprocating motion. Dependent on the test additional coils can be installed on the tester to double the force range

High Accuracy Position Control

The most accurate and precise displacement control in the market. Up to 1nm resolution and micron level of accuracy. Extremely low noise. High responsiveness for dynamic performance of system.

Environmental Control

Study fretting wear across a wide range of temperature.

Unmatched Waveform Control

Without the friction of rolling or bearing, the magnetic flexure based design provides the control required for the most sensitive of tests. The unique controller adjusts to friction changes to maintain the stroke control in real-time.

Friction Measurement

The fretting tester comes with high frequency piezo sensors to measure real-time friction. Ultra low noise amplifiers aids in detection of minute changes in friction with ease.

Additional In-line Sensors

Sensors such as acoustic emission to detect onset of cracks, and ECR to measure surface resistance changes to gain more insight on the material interface.

Liquid Containers, Sample Holder

Customizable liquid and sample holders for standard and non standard tests.

Choose Your Fretting Tester Model

Difference in Voice Coil Power For Friction Force

All Rtec Fretting testers are constructed on flexure-based designs. The motion is imparted using electromagnetic actuators with real time stroke and wave form correction controllers. The difference in model lies in the power the coil can impart during the test.

FFT-M Series

Up to 500 N Down Force (Bench Top, Single or Dual Medium Power Coil)

FFT-1

3000 N Down Force (Floor Standing, Single High Power Coil)

FFT-2

5000 N Down Force (Floor Standing, Dual High Power Coil)

Data and Analysis

FFT series fretting wear testing instruments are optimize for friction, wear, and fretting fatigue tests at small amplitude and high frequency.

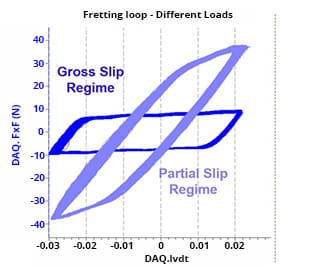

Fretting Loops

Rigid design with accurate real-time friction force allows the measure of fretting loops at different temperatures, and loads.

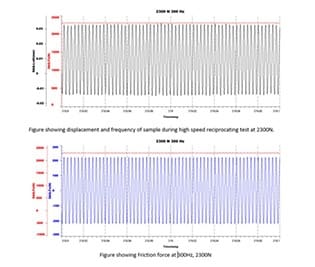

Real Time Friction Curves at 300 Hz, 3000 N

The graph shows real-time friction data at 300 Hz, 2300 N test on dry material fretting test.

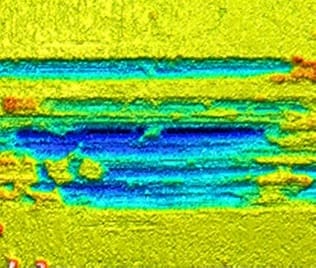

Fretting Failure Marks

Rtec-Instruments’ 3D optical profilometer allows to create 3D images of surfaces with ease.

Fretting Wear Tester Solutions

Due to multiple fretting options, the fretting tester FFT Series is used extensively across a wide range of industries:

Aerospace

- Wear Resistance

- Fretting

- Thermal Spray Coatings

- High Temperature

Automotive

- Fretting and Wear Resistance

- Engine Related Tests

- Tribology, Friction, and Wear

Bio-materials

- Corrosion

- Fretting

Ceramics

- Wear Resistance

- Fretting and Friction Testing

Lubricants

- HFRR

- Wear Resistance and Friction

Metal

- Fretting

- Tribology and Friction Testing

Optics and Glasses

- Fretting and Wear Resistance

Pharmaceuticals

- Wear and Friction

Semicon

- Fretting

- Wear Resistance

- Tribology and Friction Testing

Need Versatile Fretting Testing?

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved