Air Jet Erosion Tester Overview

Main Features:

- Conforms to ASTM G76, ASTM G211-14

- Automatic in-line sample and particle velocity measurement

- Open platform allows mounting real samples and test coupons

- Fully automatic – run and test data with a click of a button

The Rtec Instruments Air Jet Erosion Tester (AJ-1000) is a state-of-the-art solution for accurate air jet erosion testing of materials and coatings. Designed to perform repeated impact tests, the AJ-1000 directs a high-velocity jet of gas carrying abrasive particles onto the sample surface to precisely measure erosion rates. This advanced tester offers closed-loop temperature control up to 1000°C, enabling erosion studies under extreme environmental conditions. With the ability to vary abrasive particle type, shape, size, temperature, and impact velocity, the AJ-1000 provides a reliable way to rank and compare the erosion resistance of diverse materials and protective coatings.

Need help or have a question?

AJ-1000 Features

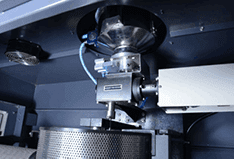

Automated Positioning Stage

An automatic stage moves the sample for ease of use. Meanwhile, the velocity measurement system provides precise measurements.

Uniform Temperature

The AJ-1000 can go up to 1000 °C temperature (multiple ranges available). As a result, study the effect of temperature with in-line temperature monitoring and PID closed loop control.

Closed loop High Speed Double Disc Velocity Measurement

The time-of-flight of the particles is determined over a controlled path length between two rotating disks. Servo controlled rpm, high speed double disc velocity for precise process control in real time.

Mixing and Impingement Angle

Software parameters control the mixing of hot air and erodent particles. In addition, the angles of impingement change to various positions – from 0 to 90 degrees.

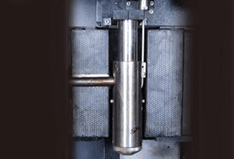

Erodent Particle Feed System

Stainless steel hoppers and vibrator with programmed motorized screw conveyor.

Erodent feed rate– 1 -10 gm/min (higher range available)

Particle hopper capacity– up to 3 liter (multiple ranges)

Particle speed– 30-200 m/sec (multiple ranges available)

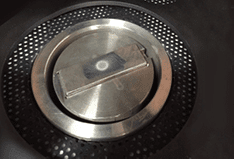

A Look Inside the AJ-1000

Each AJ-1000 includes an air pressure controller and a pressure gauge. Standard or user selected abrasive media are capable of evaluation.

Internal

Erosion Sample

High Temperature Furnace

Solution To

Aerospace

- Abrasion, Erosion Resistance

Metal

- Air Jet Erosion

Polymer

- Jet Erosion

Need Versatility?

Want Indentation and Scratch Testing?

Check out our Indentation and Scratch tester, the SMT-5000.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved