The PiQ Nanoindenter SMT-2000 Features & Benefits

Key Features:

- Closed-Loop Down Force Control

Real-time measurement and control of applied force

Programmable constant, linear, or step force profiles - True Force and True Depth Sensors

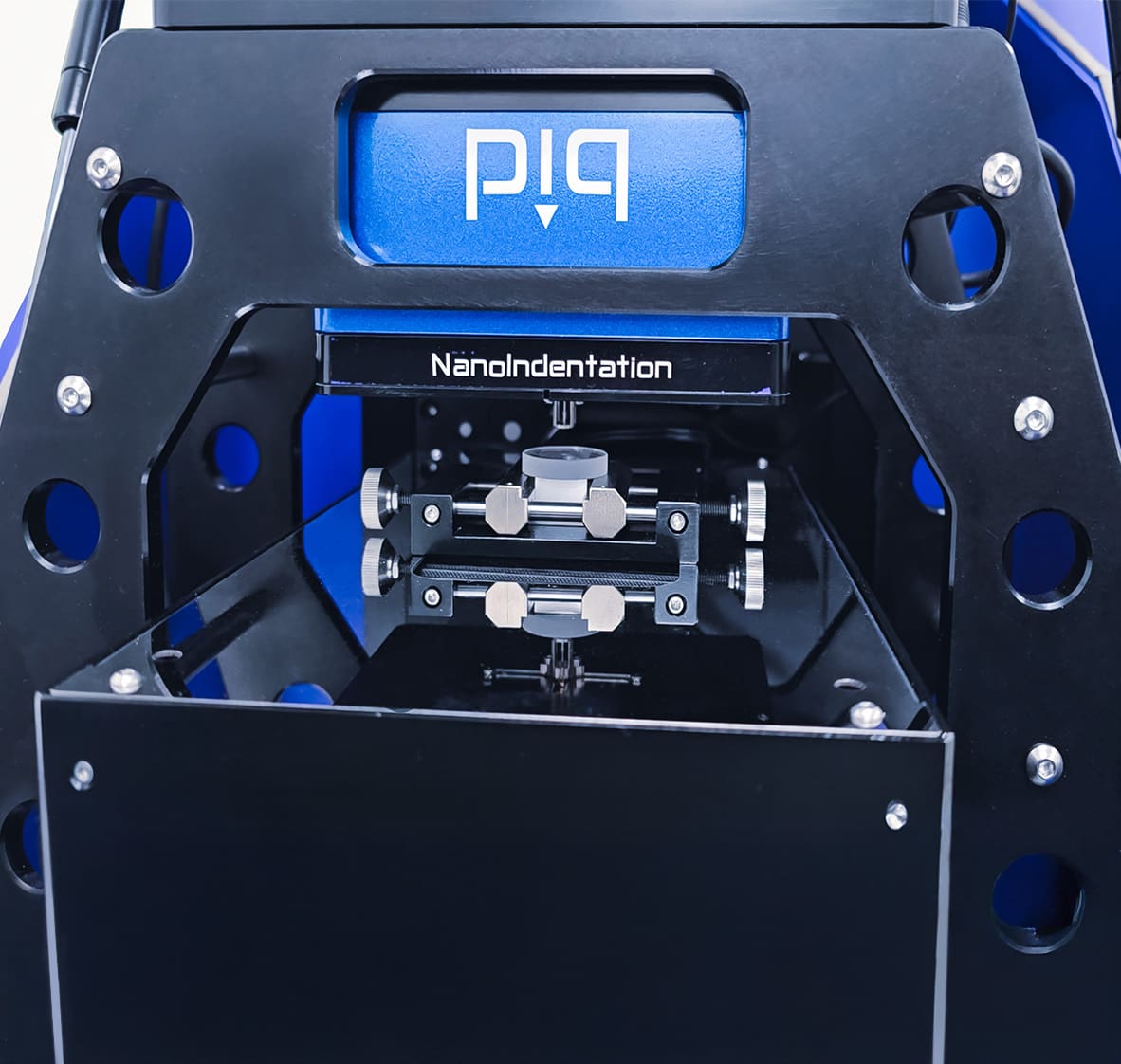

Real force and depth sensors with unique capacitive technology - Smart Nanoindenter Head

Force programmable and removable reference for the lowest frame compliance

(< 0.01 mm/N) - X, Y, and Z Motorized Tables

For indentation matrices and fully automated processes, a 3-axis motorized stage with a resolution of 20 nm - High Reliability – Robust Design

Soundproof enclosure for a compact SMT-2000 platform with integrated vibration-damping - Optional Optical Microscope

Recognizing the importance of visual inspection, the SMT-2000 can be equipped with an optical microscope for precise test area selection and post-test impression visualization (5 Mpx camera) - Full Digital Controller

Embedded state-of-the-art data acquisition controller connected with only one USB cable - Compliant with International Standards

Fully adheres to ISO 14577 and ASTM E2546-15 standards, ensuring that measurements are consistent with global industry requirements

What Is A Nanoindentation Test?

A nanoindentation tester is an instrument used to measure the mechanical properties of materials on a microscopic scale, typically at the nanometer level. This technique is beneficial for studying thin films, coatings, or small volumes of materials, where traditional methods may not be practical or feasible.

Why Choose the SMT-2000 Nanoindenter?

The SMT-2000 Nanoindenter is a state-of-the-art nanoindentation tester that combines piezo actuation and capacitive sensing technologies into a smart nanoindentation head. The SMT-2000 brings the highest precision measurements of mechanical properties, such as Hardness, Elastic Modulus, Creep, and many others.

Besides the IST module, the SMT-2000 incorporates environmental modules (temperature, humidity, corrosion). These capabilities allow the use of nano and micro indentation for quality control or cater to demanding engineers and researchers in many fields. This flexibility makes the SMT-2000 ideal for quality control, advanced materials research, and demanding R&D environments.

Need help or have a question?

A Nanoindentation Tester Like No Other

The SMT-2000 PiQ Nanoindenter is a compact, precise, and robust mechanical surface property analysis tool.

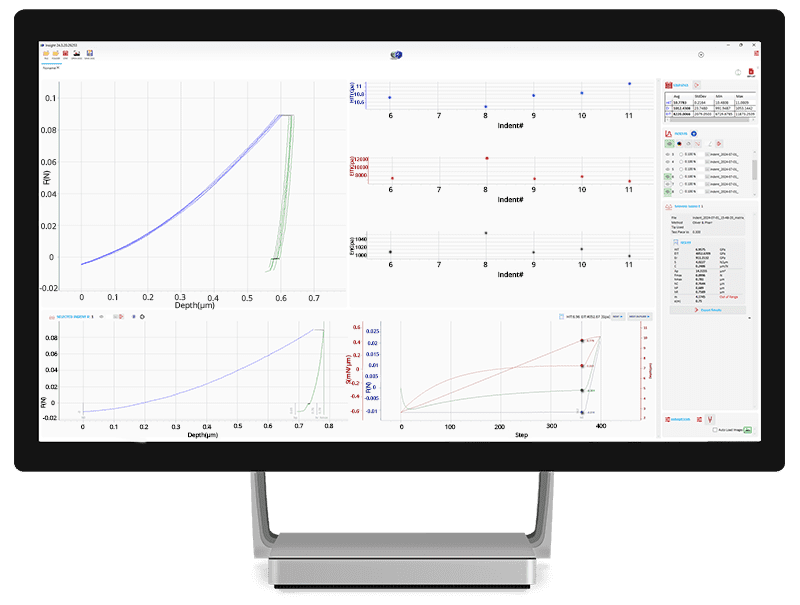

3D Imaging of Nanoindentation with Indentation Analysis and Insight

Nanoindentation Technology and Hardness Testing

What is nanoindentation hardness testing?

Nanoindentation hardness testing is a technique used to measure a material’s mechanical properties, such as hardness and elastic modulus, at the micro and nanoscale. A precision nanoindenter, such as the SMT-200, applies a controlled load to the surface, and the depth of penetration is analyzed to determine material performance. This method is widely used for coatings, thin films, and advanced materials where traditional hardness tests are not practical.

How does a nanoindenter measure modulus and hardness?

A nanoindentation tester measures hardness and modulus by recording the force applied by the indenter tip and the corresponding penetration depth. The load–displacement curve is analyzed using instrumented indentation testing methods (IIT) providing measurements of hardness, elastic modulus, and other surface properties critical for research and industrial applications.

The Nanoindenter Solution

Aerospace

- Thermal Spray Coatings

- Turbine, engine, components

- Anti corrosive coatings

Automotive

- Marr Resistance

- Thermal Spray Coatings

- DLC

- Paints

Bio-materials

- Bio compatible coatings

- Medical devices

- Joints

- Valves, pumps

Ceramics

- Ceramic coatings

- Bulk materials

Hard Coating

- Cutting tools

- Thermal spray

- DLC

Metal

- Bulk Materials

- Coatings

- Textured surfaces

Optics and Glasses

- Lenses

- Touch screen

- Consumer goods

Pharmaceutical

- Coatings on tablet

Polymer

- Marr resistance

- Coating

- Bulk materials

Semiconductor

- Screens

- Thin coatings

- Protective coatings

- Consumer goods

Need Scratch and Indentation Testing?

Take a look at the versatile SMT-5000 Surface Materials Tester for micro and macro scratch and indentation.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved