Home > Tribometers > Anwendungen >

ASTM D2783-19

Measurement of Extreme Pressure Properties of Lubricating Fluids

Four-ball Method

Differentiate between lubricating fluids having low, medium, and high level of extreme-pressure properties with the 4-ball ASTM D2783-19 method.

Summary of the ASTM D2783-19 Standard

This test method is used to assess the load carrying properties of lubricating fluids under extreme pressure conditions. The test is performed by rotating a ball against three balls in a container submerged under the test lubricant at various contact pressures, till failure is observed. Three determinations are made:

- Load-Wear Index

- Last non-seizure load

- Weld Point, by means of the Four-Ball Extreme Pressure (EP)

These tests are done using Multi-functional tribometer MFT-5000. During the test inline torque, down force, acoustic emission, electrical contact resistance and temperature values are recorded and reported. The test involves increasing load in steps of 10 seconds each till the balls are welded. The fully automated linear loading mode of MFT-5000 tester also allows to run the same test in one step by applying a linearly increasing force at a controlled rate vs. multiple steps each at constant load.

Four-ball Method Parameters

| Balls: | AISI standard steel No. E-52100 Grade 25 EP (100Cr6) |

| Ball diameter: | 12.7 mm |

| Normal Force: | Step increasing load (6, 8,10,13,16, 20, 24, 32, 40, 50, 63, 80, 100, 126, 160, 200, 250, 315, 400, 500, 620, 800) Kgf |

| Test Duration: | 10 seconds for each step |

| Speed: | 1760 rpm |

| Temperature: | Ambiant (27 °C) |

| Lubrication: | Lubricating Liquid |

| Data: | Torque (Tx) Normal Force (Fz) Frequency (Hz) Temperature (°C) |

Data Summary

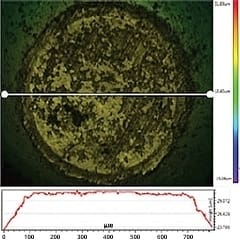

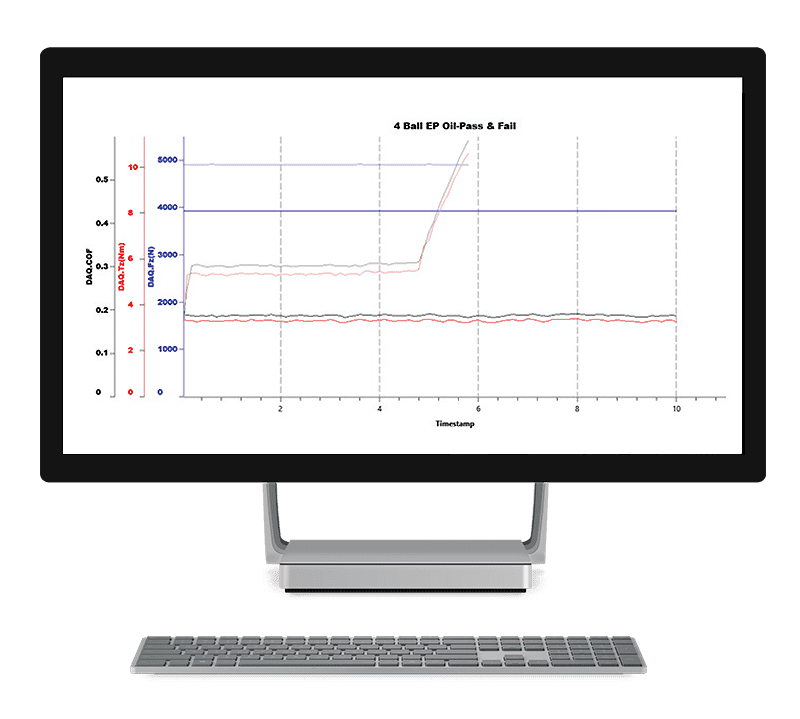

Representative test results are shown below. In the following example a lubricant that passes (does not seize) at 400Kg and welds at 500 Kg is shown. The MFT-5000 with its inline torque sensor also provides real time torque measurements along with the pass/fail criteria. The load wear index is calculated from the average wear diameter of these balls.

More on the Multi Function Tribometer (MFT-5000) Hardware

- Quad force load sensor (10,000 N)

- Torque sensor (22.6 Nm)

- Upper rotary module

- Four-ball module container assembly

- Temperature chamber

- Integrated 3D profilometer

Möchten Sie mehr erfahren?

Kontaktieren Sie uns und fordern Sie eine Demonstration an.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved