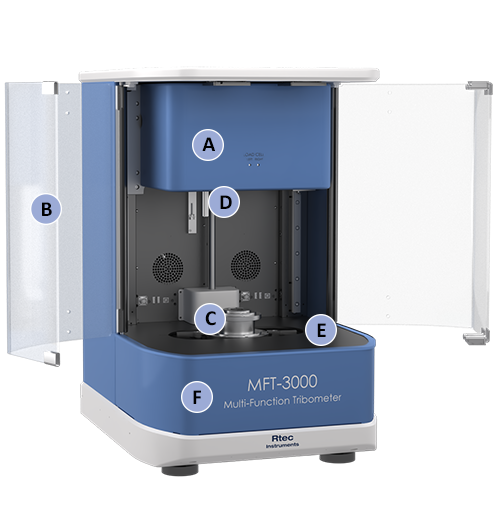

Tribometer MFT-3000

- Patented dual load sensor technology

- Load Range Nano, Micro, Macro

- -50 °C to 1000 °C

- Modular with Interchangeable Modules

The state-of-the art Multi Function Tribometer MFT-3000 is a versatile and technologically advanced bench top tribometer. With next generation patented dual force sensor technology, it generates friction tests from nano to macro test range with great accuracy. With ultra high resolution, high speeds, and a wide environmental control range, several tribological applications possible with ease.

Need help or have a question?

A Bench Top Tribometer Like No Other

A dual sensor tribomter like no other. Customizable for your needs.

Platform

Rigid heavy duty construction design to conduct tribology tests on a bench top design

Environmental control

Wide temperature (-50 °C to 1000 °C), humidity (5 to 95% RH), tribocorrosion and many more chambers available on the same platform

Lower Interchangeable Test Module

Interchangeable fast-exchange test modules

Dual Force Sensor

Dual simultaneous mounted patented range sensors from mN to 3000 N.

X Stage

High precision 150 mm X stage to move test modules automatically

Data Acquisition, Motion Controller

Advanced high speed, low noise, multiple channel, fast feedback and highest data acquisition rate (200KHz) controllers

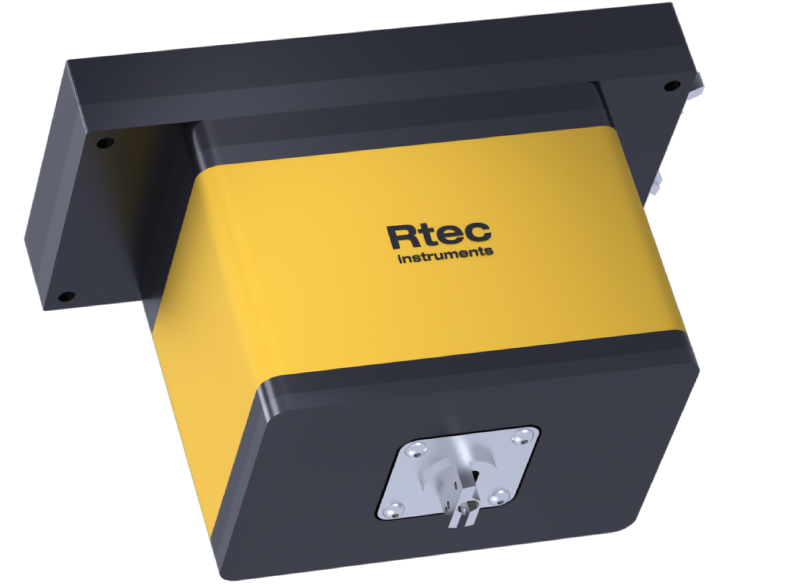

Interchangeable Modules

Multiple modules can be added on top of the XY stage:

Patented Dual Sensor Technology

- Automatically change from nano to macro force range.

- Full range available on same setup: No removing or interchanging sensors.

- Highest resolution across the entire range.

- Automatic sensor recognition.

Unmatched Load Cell Technology

Capacitive, Piezo, And More

The universal mechanical tester MFT-3000 has a wide range of patented load cells providing unparalleled stability and resolution. Additionally, the wide load range extends from nN to 3,000 N with easy interchangeable load cells.

Capacitive Load Cells

Highest resolution load cells with rigid design

Strain Gauge Load Cells

Sensors with widest load range

Piezo Load Cells

Highest resolution load cells with high frequency response

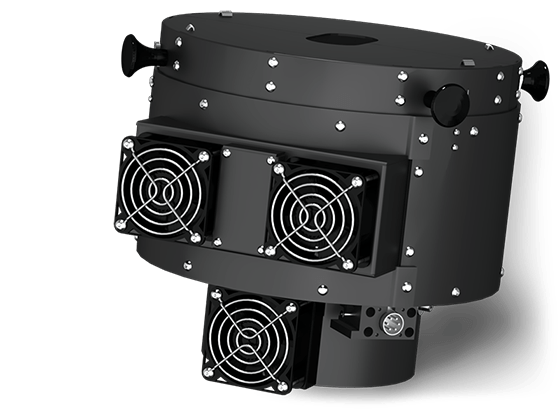

Environmental Chambers

High Heat and Cryogenic

Cryogenic to high temperature close loop chambers. -50 °C to 1000 °C

Controlled Humidity

Control humidity from 5 to 95% RH to simulate real life scenarios

Environmental Control

The Bench Top Tribometer Solution

Due to its multiple configurations, the MFT-3000 tribometer provides analysis for a wide range of industries:

Aerospace

- Thermal Spray Coatings

- Wear Resistance

- Fretting

- Vacuum

- High Temperature

- Cryogenic

- Abrasion, Erosion Resistance

Automotive

- Brake Testing

- Marr Resistance, Scratch Adhesion

- Thermal Spray Coatings

- Oil, Lubricant, Additives Testing

- Fretting and Wear Resistance

- Engine Related Tests

- Tribology, Friction, and Wear

Bio-materials

- Coatings Adhesion

- Scratch Resistance

- Fretting and Wear Resistance

- Corrosion

Ceramics

- Scratch Resistance

- Tribology and Friction Testing

Hard Coating

- Indentation

- Scratch Resistance

- Fretting

- Turning and Tapping Torque

- High Temperature

Lubricants

- Block on Ring, Timken, OK, EP

- 4Ball Wear and EP

- Rotary pin, ball, ring on disk

- HFRR

- SRV

- Tapping Torque, TCT, Drilling

- Piston Ring Liner

- Thrust Washer

- Low Temperature Testing

- High Temperature Testing

- Linear Reciprocating

- Variable Rolling to Sliding

Metal

- Hot Hardness

- Scratch Hardness

- Tribology and Friction Testing

- High Temperature

Optics and Glasses

- Scratch Resistance

- Indentation

Pharmaceutical

- Tribology and Friction

Polymer

- Scratch Resistance

- Indentation

- High Temperature

- Turning and Tapping Torque

Semicon

- Indentation

- Scratch Resistance

- Tribology and Friction Testing

Need More Versatility?

Need Compact Tribology?

Check out the benchtop Multi Function Tribometer, the MFT-2000.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved