SRV Testing on MFT-5000 Overview

Main Features:

- 5 micron to 4 mm Stroke, Up to 500 Hz oscillating frequency

- High resolution piezo sensors

- Electromagnetic Coils

- -40 to 500°C (optional 800°C) temperature

- 3000 N down force

- Rigid designs provide plot fretting loops

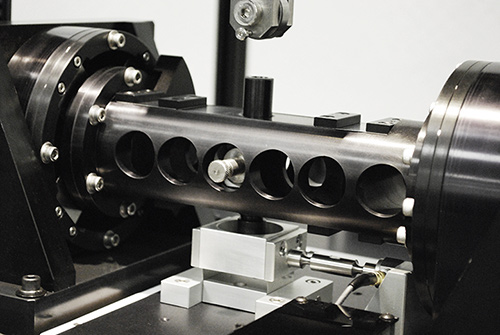

Rtec’s Tribometer SRV test system measures the coefficient of friction and wear between a lubricant, oil, grease, and two specimens in a loaded contact in linear oscillatory motion from 5 micron strokes. The sliding reciprocating friction module has a wide load, speed, and temperature range. Using various combinations of test conditions, it can test friction and wear data using several ASTM, DIN, ISO standards on the same tester.

Need help or have a question?

Learn More About The MFT-5000 Platform

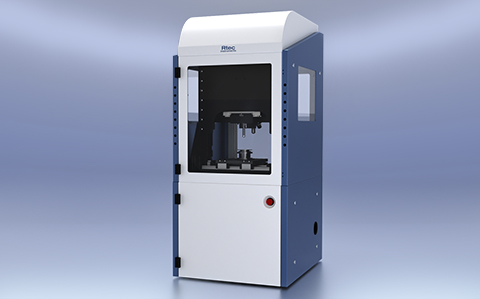

The MFT-5000 Tribometer

Learn more about the versatile MFT-5000 tribometer that provides friction, wear, and surface properties of various materials under a multitude of environments and testing conditions.

Linear Oscillating/Fast Reciprocating Test,

SRV Test

The MFT-5000 is set apart by its environmental control, reliability on long and short tests, and position and force sensors that provide control under any condition. High accuracy and thorough data every time.

Standard tests determines extreme pressure, friction wear properties of greases, solid bonded films, gear/hydraulic fluids, and lubricant oils. All tests are done in oscillation mode under controlled environmental conditions. ASTM G119, G174, G133, G203, G204, G206, D5706, D5707, D6425, D7217, D7420, D7594, D7421, DIN 51834 and more.

The SRV Testing Solution

Because the MFT-5000’s SRV module is so versatile, it is used extensively across a wide range of industries:

Automotive

- Oil, Lubricant, Additives Testing

- Engine Related Tests

Lubricants

- Oil, Lubricant, Additives Testing

The MFT-5000 Has More To Offer

Need Focused SRV Testing?

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved